Preparation method of environmental-friendly type pressure-sensitive oil for carbonless copying paper

A carbonless copy paper, environmentally friendly technology, used in paper, papermaking, paper coatings, etc., can solve the problems of large VOCs emissions, non-compliance with environmental protection, unfavorable to human health, etc., achieving excellent compatibility and synergy, easy to micro Encapsulated, safe to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

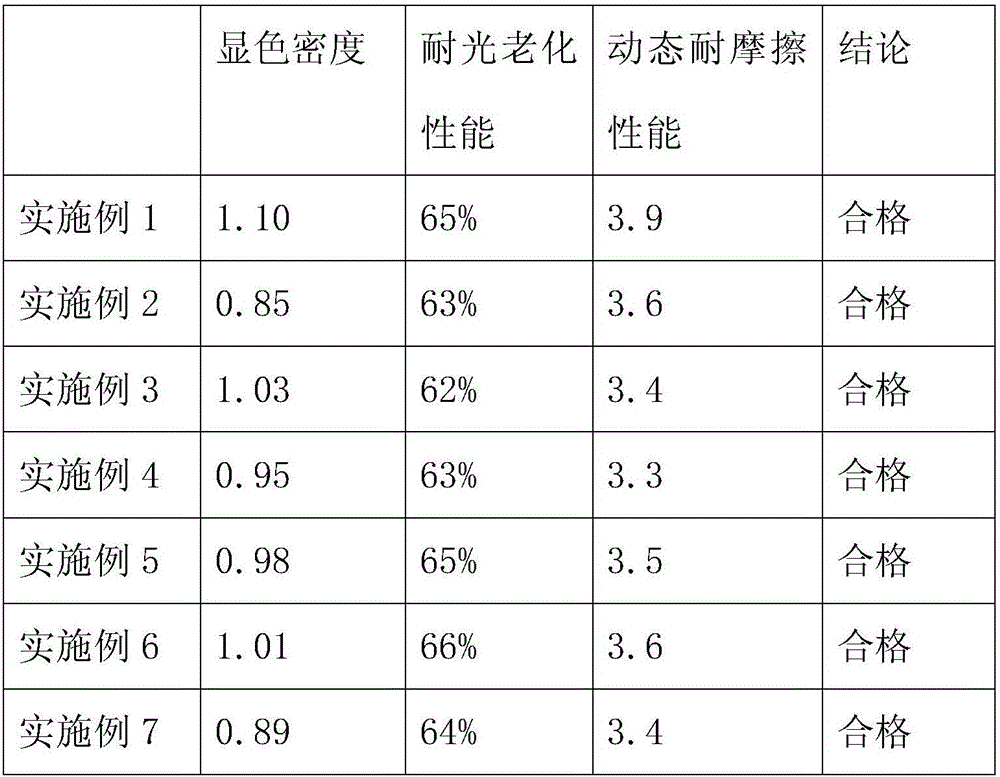

Examples

preparation example Construction

[0034] A preparation method of an environment-friendly carbonless copy paper pressure-sensitive oil, the preparation method comprising the following steps:

[0035] 1) Pretreatment: Heat the solvent oil compound to 60-70°C and stir evenly;

[0036] 2) Dissolving: under the condition of temperature 110°C-130°C, heat and dissolve 2-6 parts by weight of leuco dye and 20-40 parts by weight of solvent oil to obtain a chromogenic agent; wherein, the colorless dye is phenolic, phenothione One or more of azine series and fluorane series, phenol series can be crystal violet lactone (CVL), malachite green lactone (MGL), phenothiazine series can be benzomethylene blue (BLMB), fluoran series It can be fluorane black; solvent oil is prepared from the following components in terms of mass percentage: 0-40% of component A; 40-100% of component B, 0-20% of chloromethyl ester; Divided into vegetable oil or vegetable oil methyl ester, the B component is epoxidized vegetable oil or epoxy methyl...

Embodiment 1

[0043] A preparation method of an environment-friendly carbonless copy paper pressure-sensitive oil, the preparation method comprising the following steps:

[0044]1) Pretreatment: heat the solvent oil compound to 60°C, and stir evenly; the solvent oil is prepared from the following components in mass percentage: 60% epoxy soybean oil; 20% chloromethyl ester, castor oil 20%;

[0045] 2) Dissolving: at a temperature of 110°C, 2 parts by weight of CVL and 30 parts by weight of solvent oil were heated and dissolved to obtain a color developing agent;

[0046] 3) Pre-emulsification: Add 5 parts by weight of emulsifier, 20 parts by weight of urea-formaldehyde resin and 43 parts by weight of deionized water to the chromogenic agent obtained in step 2) and mix, then stir at a stirring speed of 800r / min; Among them, the emulsifier is composed of calcium dodecylbenzenesulfonate and styrylphenyl polyoxyethylene ether in a mass ratio of 6:4;

[0047] 4) Emulsification: Carry out high-s...

Embodiment 2

[0052] A preparation method of an environment-friendly carbonless copy paper pressure-sensitive oil, the preparation method comprising the following steps:

[0053] 1) Pretreatment: Heat the solvent oil compound to 63°C and stir evenly; the solvent oil is prepared from the following components in mass percentage: epoxy soybean oil 65%; chloromethyl ester 15%, palm oil 20%;

[0054] 2) Dissolving: at a temperature of 120°C, 2 parts by weight of MGL and 30 parts by weight of solvent oil were heated and dissolved to obtain a chromogenic agent;

[0055] 3) pre-emulsification: in step 2) in the chromogenic agent that obtains, add the polyacrylamide of 5 weight parts, the chitosan of 20 weight parts and the deionized water of 43 weight parts and mix, then stir, stirring speed is 900r / min;

[0056] 4) Emulsification: Carry out high-speed shear emulsification to the required particle size of the capsule, the shear speed is 8000r / min, and the shear time is 5min to obtain the emulsio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com