Label wheel rotary printing machine

A printing machine, label technology, applied in the direction of rotary printing machine, printing machine, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

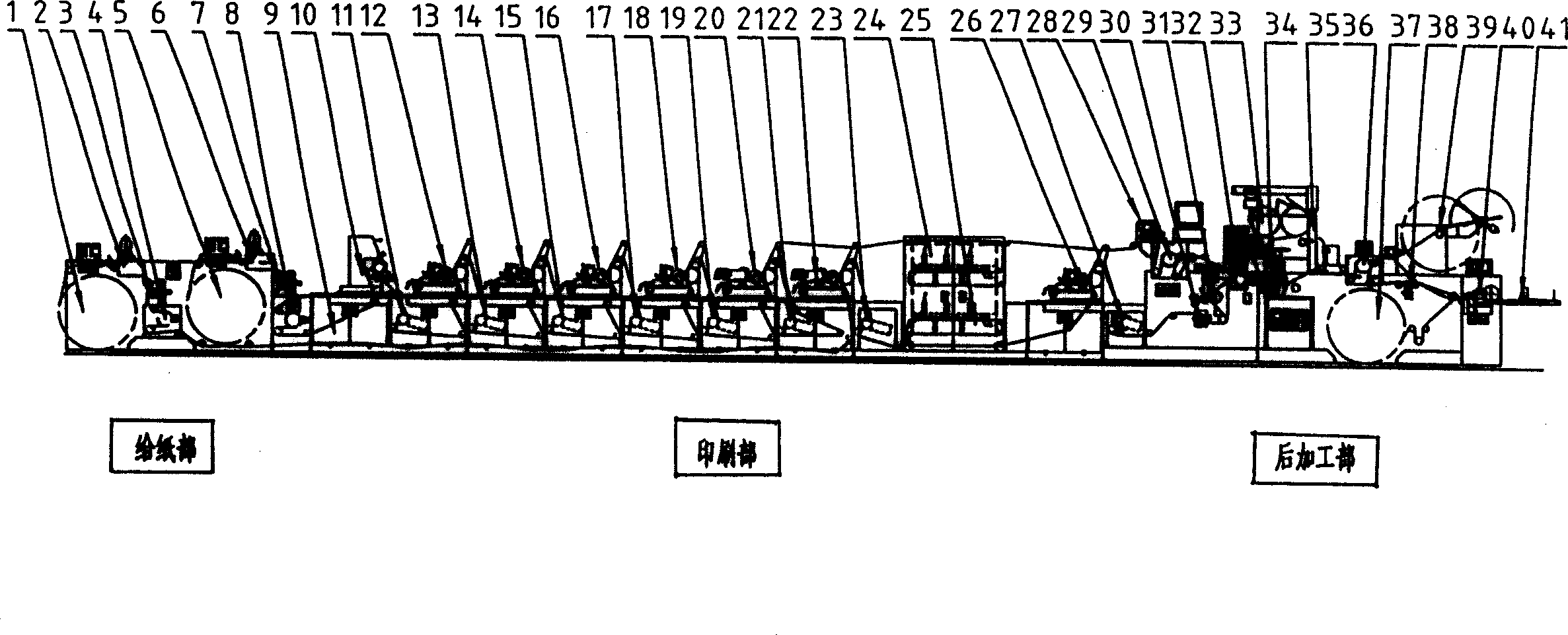

[0030] As shown in FIG. 1 , it is a structural schematic diagram of a label rotary printing machine. The label rotary printing machine is composed of three major parts: a paper feeding unit, a printing unit, and a post-processing unit.

[0031] The described paper feeder device consists of a first paper feeder 1, a corona device 2, a deviation correction device 3, a servo motor traction roller device 4 for the first paper feeder, a second paper feeder 5, a corona device 6, and a deviation correction device 7. The second paper feeding part is composed of a servo motor traction roller device 8, etc. The first paper feeding part 1 and the second paper feeding part 5 are both cantilever mounted on the G side wallboard of the paper feeding part. , The upper end of the second paper feeding part 5 is respectively installed with corona devices 2, 6, and deviation correction devices 3, 7, and the rear ends of the first paper feeding part 1 and the second paper feeding part 5 are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com