Digital carbonless copy paper

A carbonless copy paper, digital technology, applied in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of easy separation, reduced contact angle, difficult bonding strength, etc., to achieve the effect of improving hydrophobicity and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

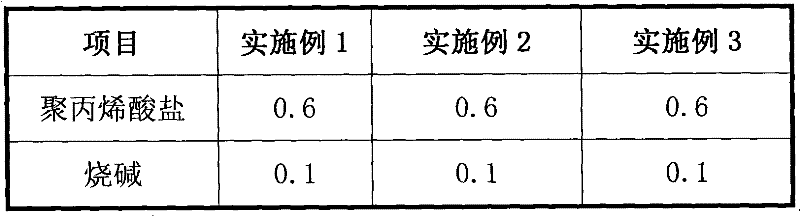

[0029] Concrete embodiment is as follows: (component content ratio is: mass parts)

[0030]

[0031]

Embodiment 1

[0033] ①Paint preparation and coating:

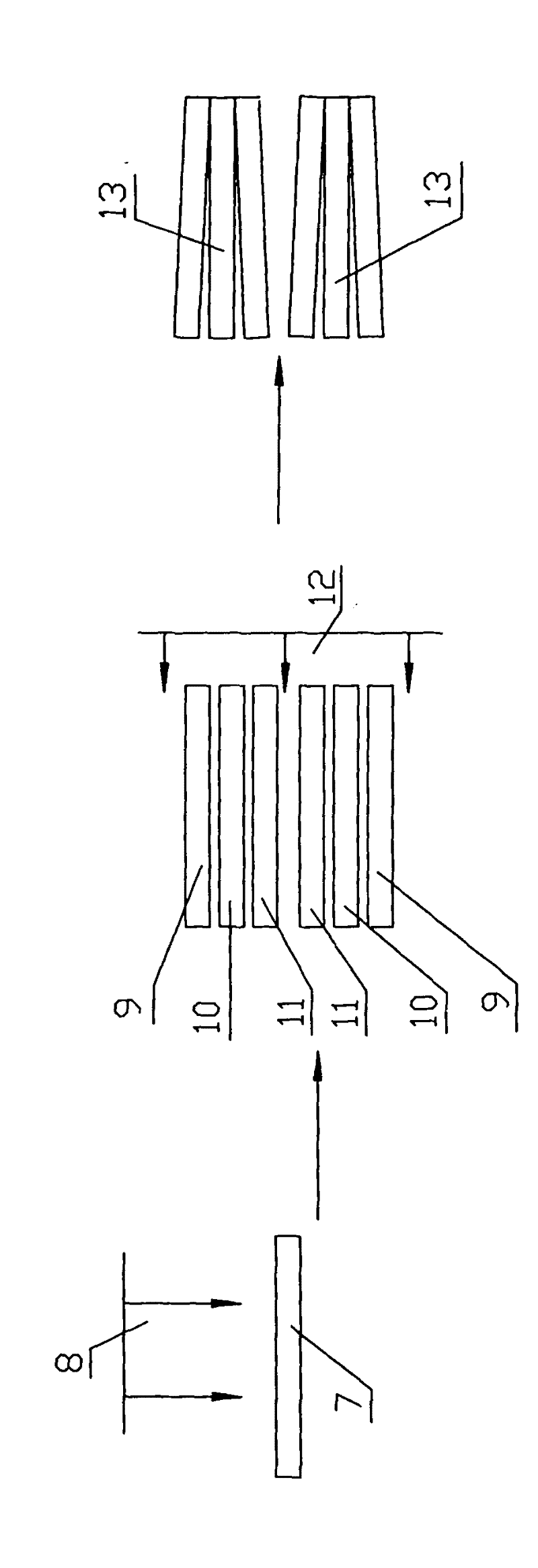

[0034] According to the above-mentioned paint addition sequence, the high-speed dispersion uniform paint, the solid content is 22%; the carbon-free copying paper produced under the curtain coating with a coating speed of 400m speed,

[0035] ②The weight of finished paper and collation:

[0036] The weight of carbonless paper is 48g;

[0037] Duplex (upper paper + lower paper).

[0038] ③Separation effect and strength:

[0039] The parts in the printed product can be separated by lightly tapping, and the bonding strength between the pages in the middle of each part is good.

Embodiment 2

[0041] ①Paint preparation and coating:

[0042] According to the above-mentioned paint addition sequence, the high-speed dispersion uniform paint, the solid content is 31%; the carbon-free copying paper produced under the curtain coating with a coating speed of 1200m speed,

[0043] ②The weight of finished paper and collation:

[0044] The weight of carbonless paper is 55g;

[0045] Triple (top paper + middle paper + bottom paper).

[0046] ③Separation effect and strength:

[0047] The parts in the printed product can be separated by lightly tapping, and the bonding strength between the pages in the middle of each part is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com