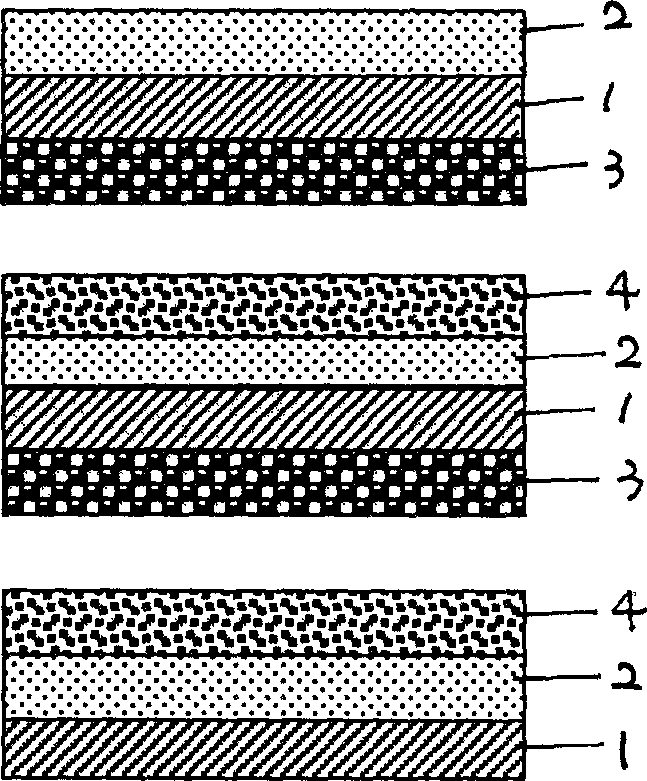

High non-transparent carbon-free duplicating paper and production thereof

A carbonless copy paper, transparent technology, applied in the field of papermaking processing, can solve the problems of non-copying or poor copying effect, low opacity and poor confidentiality of carbonless copying paper, and achieve clear writing, long storage time and good printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

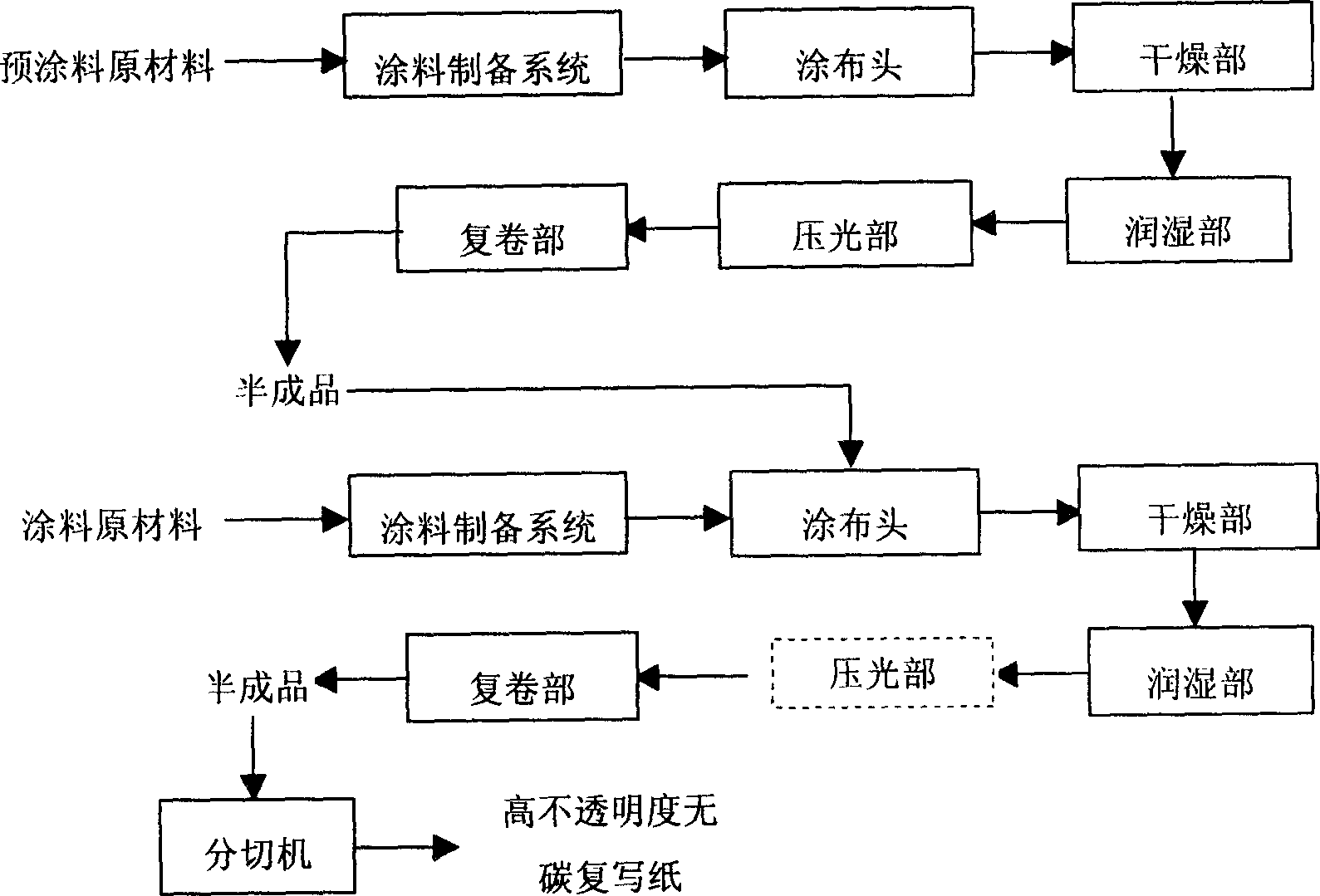

Method used

Image

Examples

Embodiment Construction

[0042] 1. Preparation of coating

[0043] 1. Preparation of pre-coating paint: Take water 150, polyacrylic acid 2, kaolin 70, calcium carbonate 30 and alumina 10 at room temperature according to the weight ratio (unit: kg / ton paper dry weight), and the line speed is 18-28m After the high-speed dispersion of / s is complete, add carboxylated styrene-butadiene latex 30, oxidized starch 4, purple dye 0.1 and blue dye 0.1 to mix, stir evenly, and set aside.

[0044] 2. Preparation of chromogenic layer coating CB: Take water 40, polyacrylic acid 1.0, starch spacer 35, microcapsules 42, carboxylated styrene-butadiene latex 8 and oxidation Mix starch 5, stir evenly, and set aside.

[0045] 3. The preparation of the color layer coating CF: take water 100, polyacrylic acid 1.0 and kaolin 130 at room temperature according to the weight ratio (unit: kg / ton dry weight of paper), and disperse at a high speed with a line speed of 18-28m / s Then add zinc salicylate resin 23, carboxylated sty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| opacity | aaaaa | aaaaa |

| opacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com