Pressure-resistant carbon-free duplicating paper and production thereof

A carbonless copy paper, pressure-resistant technology, applied in the field of papermaking processing, can solve the problems of distortion, carbonless copy paper bluish, microcapsules easily broken, etc., and achieves long storage time, clear writing on the printed surface, and good pressure resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

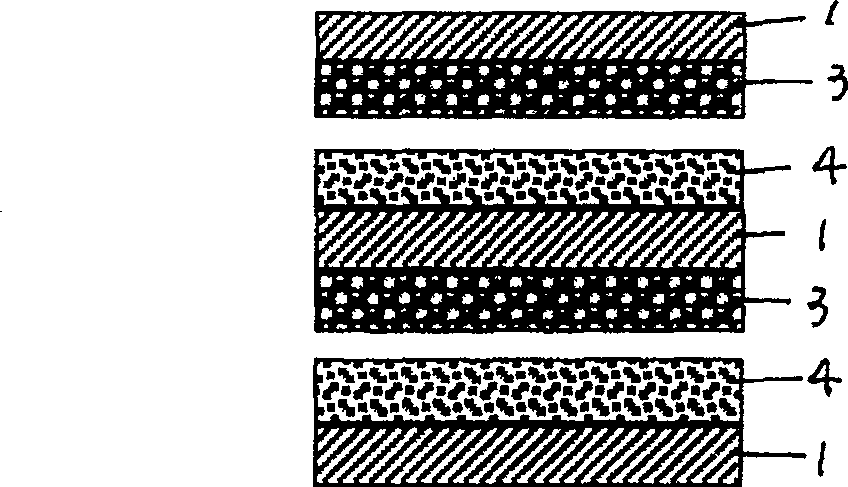

[0045] Such as figure 1 As shown, the pressure-resistant carbonless copy paper of the present invention is composed of triplets, the back of the base paper 1 is coated with the color-developing layer 3 as the first couplet; the front of the base paper 1 is coated with the color-developing layer 4, and the back is coated with three layers of the color-developing layer 3 The pressure-sensitive paper is used as the middle page, and the middle page can be multiple pages; the base paper 1 is coated with a color-developing layer 4 on the front side and is the last page.

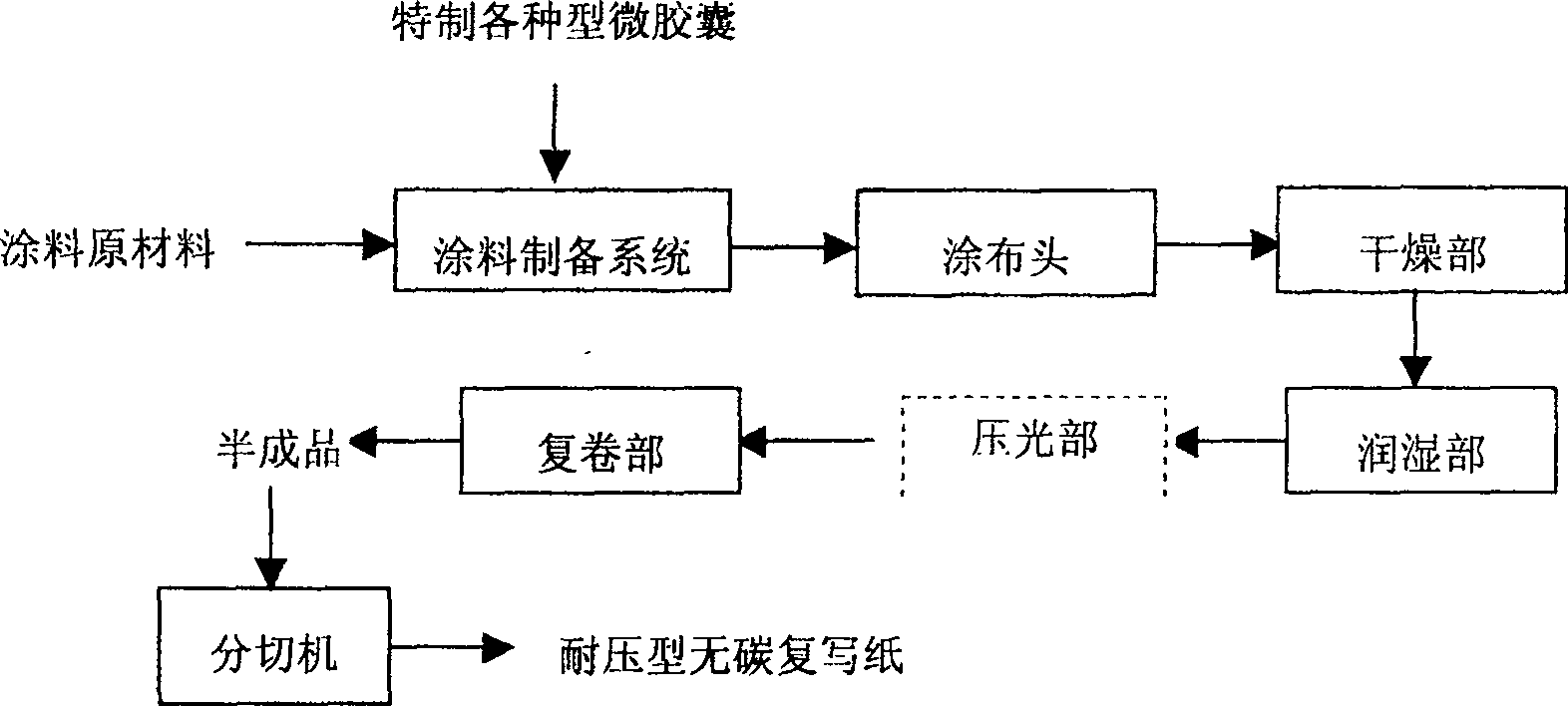

[0046] Production process for preparing pressure-resistant carbonless copy paper:

[0047] 1. Preparation of coating (unit: kg / ton paper dry weight)

[0048] 1. Preparation of microcapsules: Take 40% of water, 10% of sodium acrylate sulfamate, 12% of melamine formaldehyde resin, 37% of color oil, 15% of ammonia water, and 1.0% of formic acid at normal temperature. 28m / s, the pH value is adjusted to 3.0-5.0 during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com