Carbonless copying paper with guard wires and making method thereof

A technology of carbonless copy paper and security thread, applied in the field of papermaking, can solve the problem that anti-counterfeiting carbonless paper cannot achieve anti-counterfeiting and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

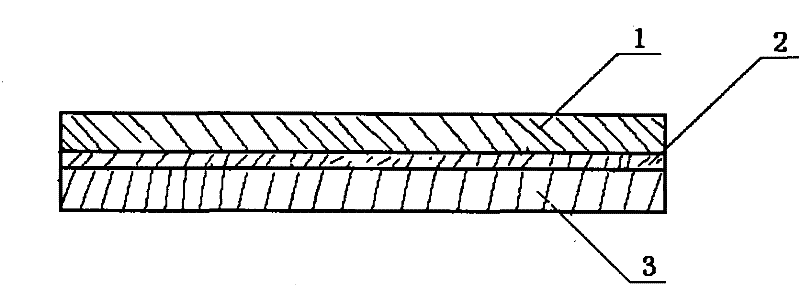

[0041] The carbonless copy paper with safety thread in this example is composed of three papers with different structures, which are divided into carbonless upper paper (CB), middle paper (CFB), and lower paper (CF). Each original paper has a safety line An anti-counterfeit security thread 2 is embedded between the upper layer pulp fiber 1 and the lower layer pulp fiber 3 of the security thread, and the embedding method is a fully embedded security thread embedded inside the processed paper; the upper paper (CB) is processed paper coated with a coating on the back of the base paper; The middle paper (CFB) is processed paper coated on both sides of the base paper; the bottom paper (CF) is processed paper coated on the front side of the base paper.

[0042] The base paper contains the following raw materials in parts by weight: 400 parts of bleached softwood pulp, 400 parts of bleached hardwood pulp, 100 parts of talcum powder, 10 parts of rosin gum, 50 parts of aluminum sulfate,...

Embodiment 2

[0062] The difference between this embodiment and embodiment 1 is:

[0063] The carbonless copy paper with safety line is composed of 5 processed papers with different structures, which are divided into carbonless upper paper (CB), middle paper (CFB), and lower paper (CF), and each base paper has a layer of fiber on the safety line An anti-counterfeit security thread 2 is embedded between 1 and the pulp fiber 3 of the lower layer of the security thread, and the anti-counterfeit security thread 2 is embedded in a partially visible window security thread. The uppermost sheet (CB) is processed paper coated on the back of the original paper; the middle three sheets (CFB) are processed paper coated on both sides of the base paper; the bottom sheet (CF ) is processed paper coated with a coating on the front side of the base paper.

[0064] The base paper contains the following raw materials in parts by weight: 600 parts of bleached softwood pulp, 600 parts of bleached broadleaf pul...

Embodiment 3

[0068] The difference between this embodiment and embodiment 1 is:

[0069] The base paper contains the following raw materials in parts by weight: 800 parts of bleached coniferous pulp, 800 parts of bleached straw pulp, 300 parts of talcum powder, 20 parts of rosin gum, 100 parts of aluminum sulfate, 20 parts of cationic starch, 50 parts of oxidized starch, polyacrylamide 2 copies;

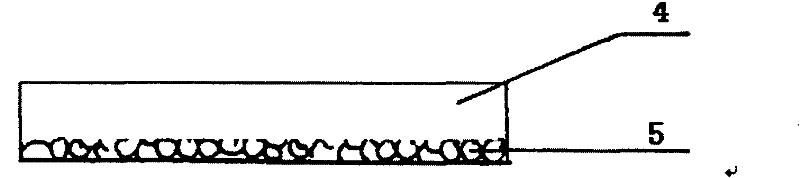

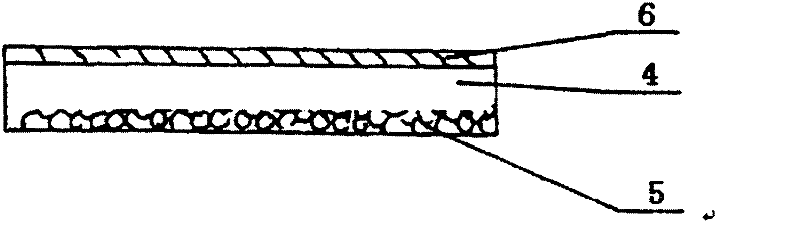

[0070] The microcapsule coating 5 comprises the following raw materials in parts by weight: 200 parts of melamine microcapsules, 80 parts of GG starch, 60 parts of tapioca oxidized starch, and 15 parts of styrene-butadiene latex;

[0071] The color developer coating 6 contains the following raw materials in parts by weight: 30 parts of tapioca oxidized starch, 120 parts of kaolin, 32 parts of activated clay color developer, 30 parts of styrene-butadiene latex, and 10 parts of sodium pyrophosphate;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com