Composite toughening material of nanometer carbon pipe/nanometer zirconium exide and its preparation method

A composite toughening material, nano-zirconia technology, which is applied in the field of carbon nanotube/nano-zirconia composite toughening material and its preparation, can solve the problems that have not been found in the relevant reports of CNTs/nano-zirconia composite toughened ceramic materials, etc. To achieve the effect of improving fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] 1. Preparation of CNTs suspension:

[0026] The CNTs prepared by the chemical vapor deposition method were boiled in HF for 2 hours to remove the amorphous carbon on the surface of the CNTs, and washed with water until pH=7-7.5. Add the acid boiled CNTs to deionized water, add 0.1-0.6% surfactant corresponding to the mass of deionized water, and ultrasonically disperse.

[0027] 2. Preparation of CNTs / zirconium hydroxide

[0028] Add zirconium chloride to the CNTs suspension, and its concentration can be adjusted according to the actual needs, according to the amount of CNTs in the CNTs aqueous suspension, ranging from ZrCl 4 The mass ratio of CNTs to CNTs is preferably 4-40. When more zirconium chloride is added, the prepared nano-zirconia particles will be more, on the contrary, there will be less zirconium oxide particles; add enough concentrated ammonia water while stirring rapidly, and a large amount of zirconium hydroxide will be formed instantly gel:

[0029] ...

Embodiment 1

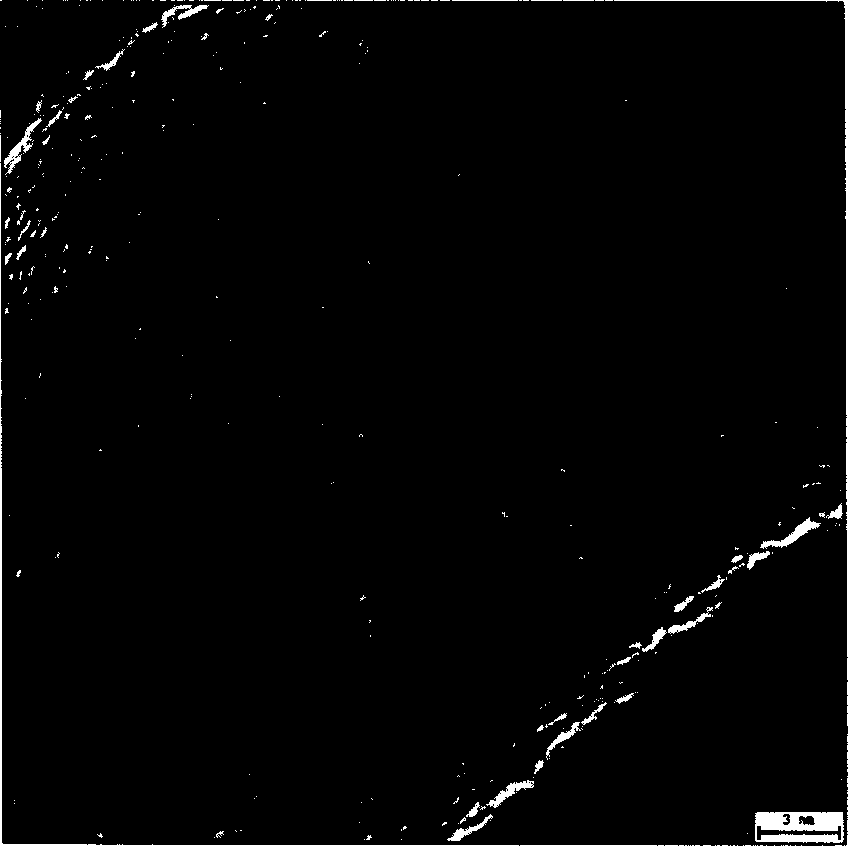

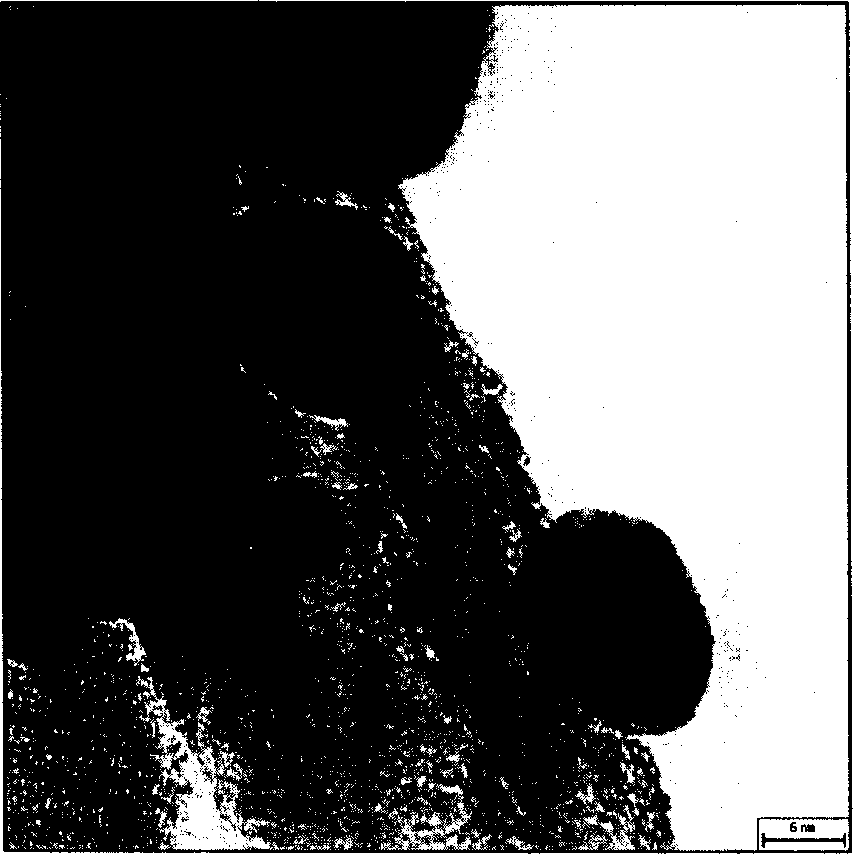

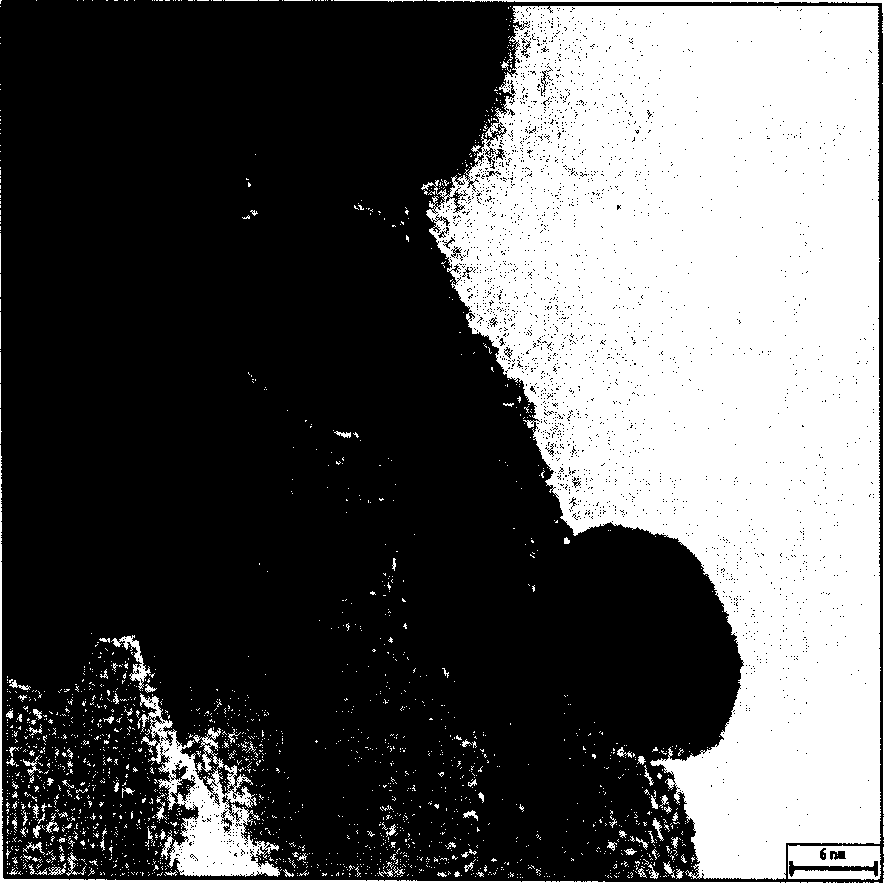

[0038] Add 0.5g of CNTs to 100ml of deionized water, add 0.1g of sodium dodecylsulfonate, and sonicate for 15min. Add 2g of zirconium chloride to the CNTs slurry and fully dissolve it. Quickly pour 20% concentrated ammonia water until no new precipitates are produced, and a large amount of zirconium hydroxide gel is formed. Filter and wash with water until neutral, dry in an oven at 100°C to remove crystal water. The XRD pattern of CNTs / zirconium hydroxide shows that zirconium hydroxide is amorphous (see Figure 2a ), SEM showed that the zirconium hydroxide particles were about 2-5nm. CNTs / zirconium hydroxide was heated in a tubular resistance furnace at 550° C. under the protection of an argon atmosphere for 3 hours, and then cooled with the furnace temperature to obtain CNTs / nanometer zirconia materials. The XRD pattern showed that zirconia had a cubic crystal structure (see Figure 2b ). High-resolution transmission electron microscopy (HRTEM) detection results (see Fi...

Embodiment 2

[0040] Add 0.15g of CNTs to 100ml of deionized water, add 0.3g of dodecyloxyamine, and sonicate for 15min. Add 4g of zirconium chloride to the CNTs slurry and fully dissolve it. Quickly pour 20% concentrated ammonia water until no new precipitates are produced, and a large amount of zirconium hydroxide gel is formed. Filter and wash with water until neutral, dry in an oven at 200°C to remove crystal water. The XRD pattern of CNTs / zirconium hydroxide shows that zirconium hydroxide is amorphous, and SEM shows that the zirconium hydroxide particles are about 10nm. The CNTs / zirconium hydroxide was heated in a tubular resistance furnace at 600°C under the protection of argon atmosphere for 2h, and then cooled with the furnace temperature to obtain the CNTs / nano-zirconia material. The XRD pattern showed that the zirconium oxide had a cubic crystal structure. High-resolution transmission electron microscopy (HRTEM) detection results (see Figure 1c ) shows that the particle size o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com