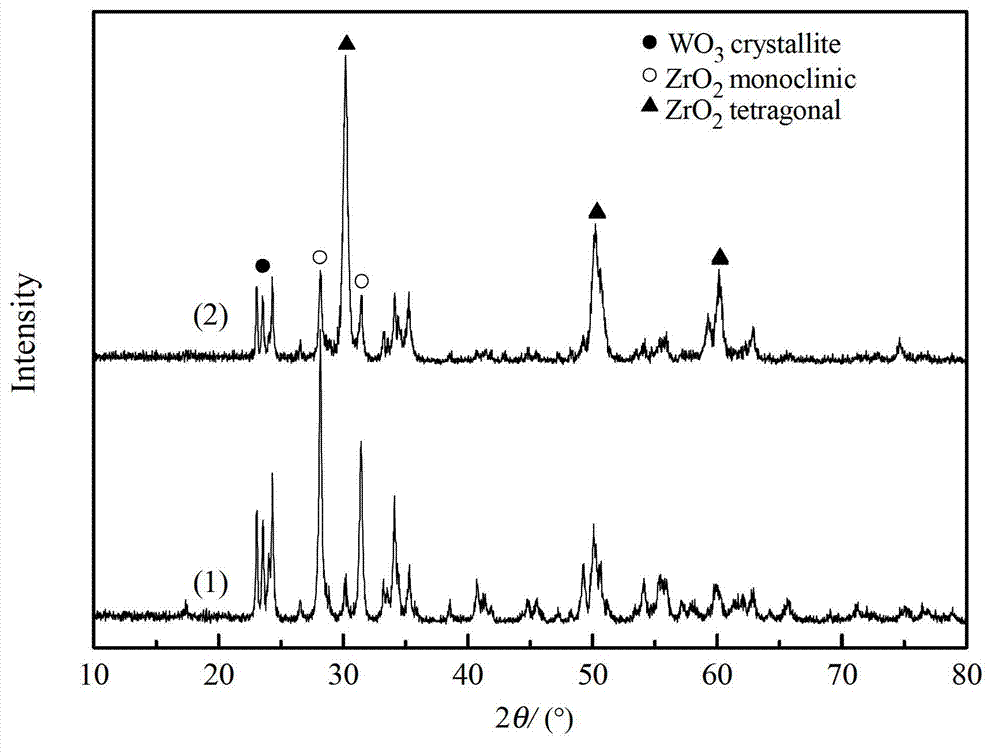

Preparation method of WO3/ZrO2 solid super acidic catalyst

A solid super acid and catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., to achieve enhanced catalytic activity, low reaction temperature, and small specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

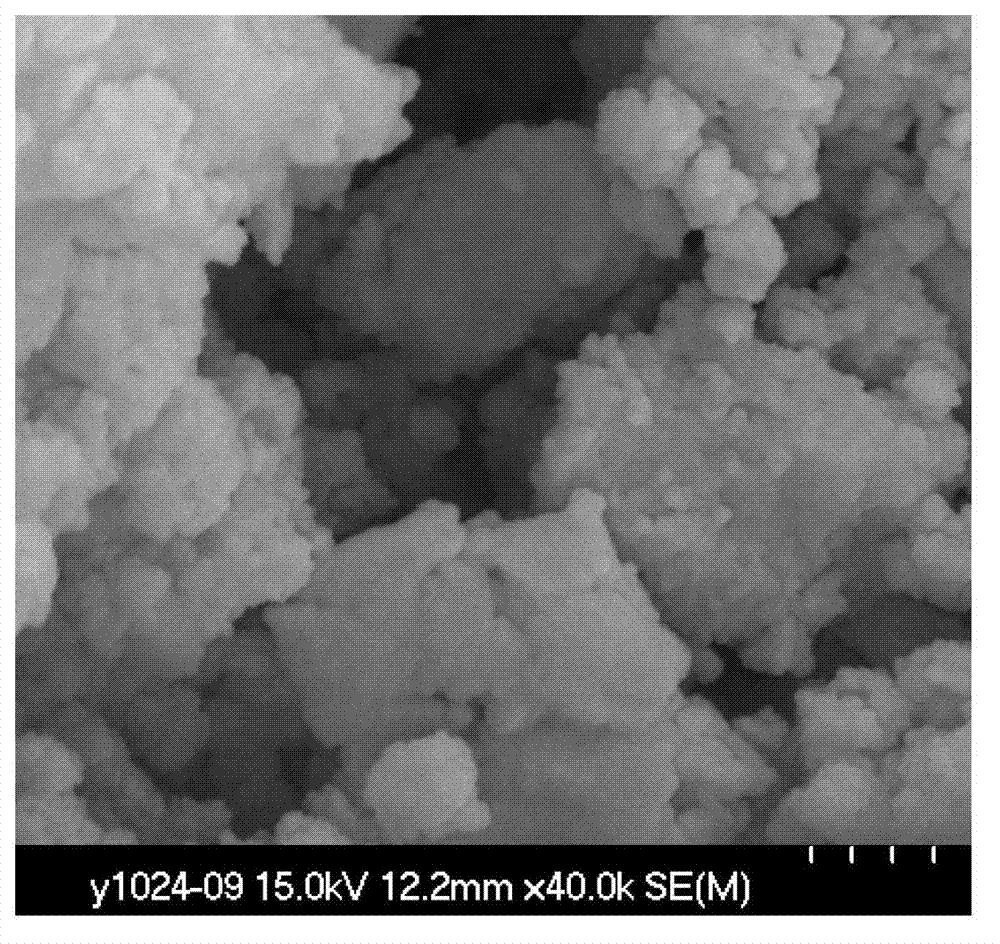

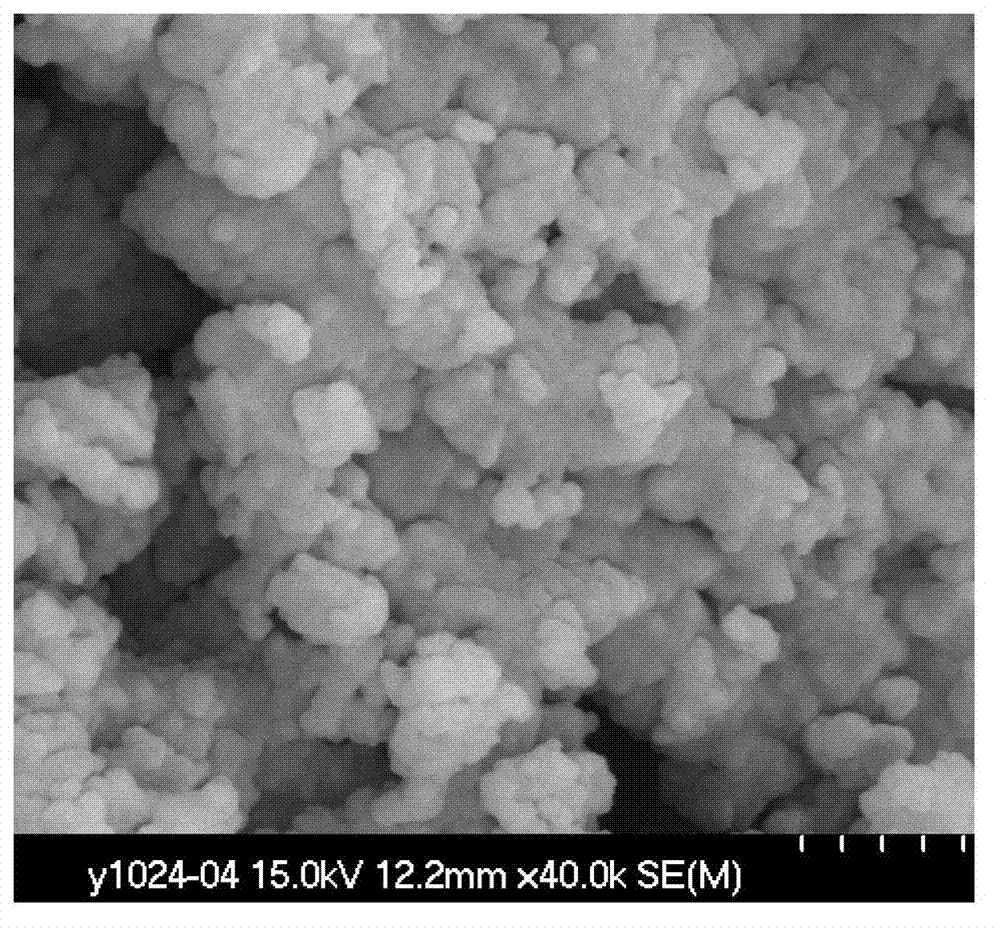

[0018] Example 1. Under the condition of stirring, add 0.6 m 3 min -1 25% volume fraction of concentrated ammonia water was added dropwise at a high speed to form a hydrogel, and the pH value was adjusted to 9~10. Stirring was continued for 1-2 hours, and after aging at room temperature for 1-12 hours, the prepared hydrogel was transferred to a round-bottomed flask connected with a condenser tube, and heated at 90-110°C for 1-12 hours. Suction filter and wash the precipitate with deionized water until there is no chloride ion. Then filter the cake in a constant temperature drying oven with a concentration of 99% C 2 h 5 Soak in OH for 1~12 hours. Take out after cooling to room temperature, filter to remove residual C 2 h 5 OH, dry at 90~120°C for 1~12 hours, grind it finely to get white powder zirconium hydroxide carrier. Then impregnate Zr(OH) with ammonium metatungstate solution (W mass fraction is 15%) 4 , calcined at 800°C for 2 to 5 hours under a static air atmos...

Embodiment 2

[0024] The catalyst was prepared according to the method of Example 1, except that the mass fraction of W in the mixture was 10%. The conversion rate of n-heptane catalyzed by the obtained catalyst and the selectivity of isoheptane were shown in Table 3.

[0025] n-heptane conversion Isoheptane selectivity Product yield 38.56 95.83% 36.95%

[0026] table 3

[0027] Note: In the evaluation of reaction performance, samples were taken for analysis after 20 minutes of stable reaction, and the test time was all over 48 hours.

Embodiment 3

[0029] The catalyst was prepared according to the method of Example 1, except that the mass fraction of W in the mixture was 18%. The conversion rate of n-heptane catalyzed by the obtained catalyst and the selectivity of isoheptane were shown in Table 4.

[0030] n-heptane conversion Isoheptane selectivity Product yield 32.81% 90.68% 29.75%

[0031] Table 4

[0032] Note: In the evaluation of reaction performance, samples were taken for analysis after 20 minutes of stable reaction, and the test time was all over 48 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com