Production of superfine mono-dispered nano-zirconium dioxide

A zirconium dioxide and preparation process technology, applied in zirconia and other directions, can solve the problems of large particles, low purity and poor dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

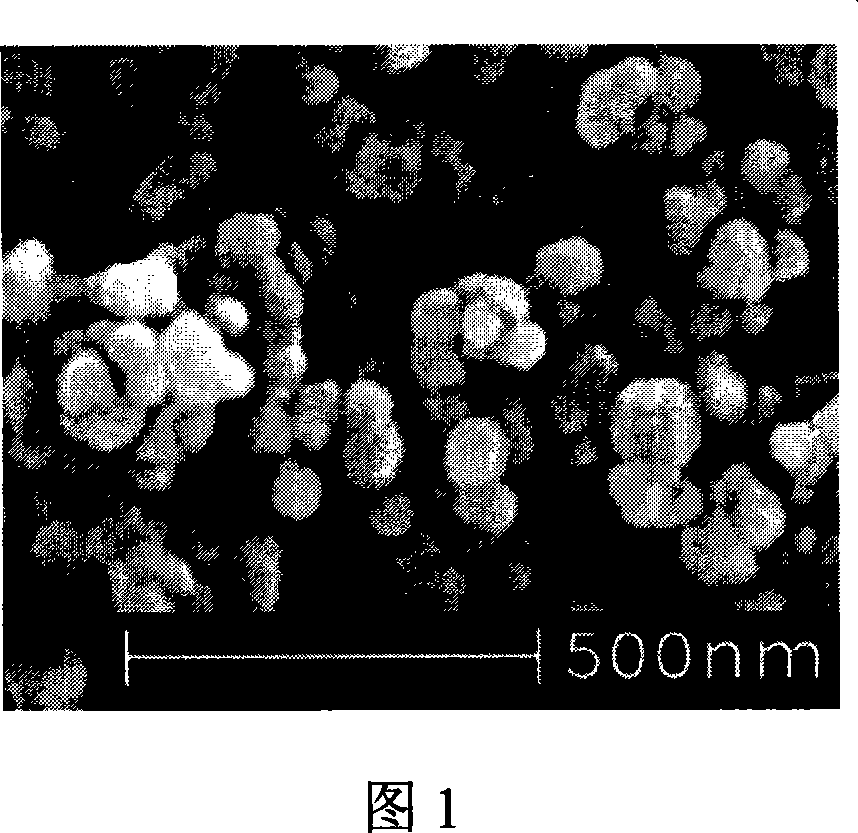

[0019] Embodiment 1: take by weighing zirconium oxychloride 120g and dissolve in deionized water, be mixed with 0.3mol / L zirconium oxychloride solution for subsequent use; Pass 40g liquid ammonia into 960ml deionized water, be mixed with the ammoniacal liquor that concentration is 4%, then add to Add 1.3g of additive to the ammonia water, the additive is a mixture of polyacrylic acid amide and polyethylene glycol mixed in a ratio of 1:1.5, after stirring evenly, slowly add the zirconium oxychloride solution into the ammonia water to react, continue stirring, and control The reaction temperature is 35°C. When the pH value of the reaction solution is detected to be 9, the feeding is stopped immediately, and the obtained zirconium hydroxide hydrosol is sent to a filter press and washed with water. When the chloride ion content in the washing water is less than 120ppm At the same time, take out the zirconium hydroxide filter cake and put it into the alcohol liquid tank and wash it ...

Embodiment 2

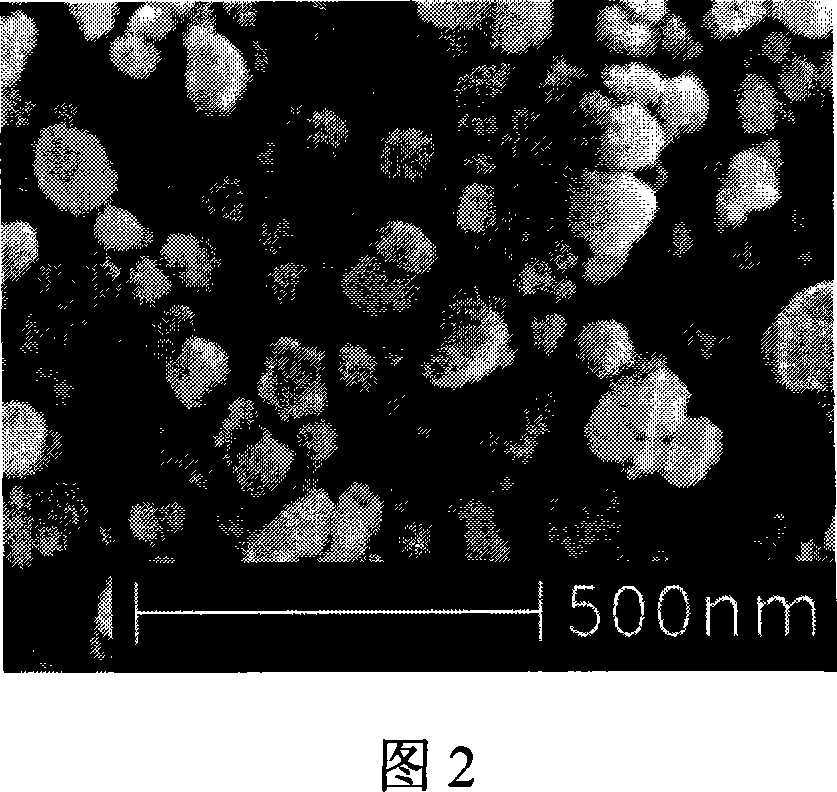

[0020] Embodiment 2: take by weighing 170g of zirconium oxychloride and dissolve in deionized water, and prepare a 0.2mol / L zirconium oxychloride solution for subsequent use; pass into 950ml deionized water in 50g of liquid ammonia, and be mixed with the ammoniacal liquor that concentration is 5%, then Add 1.0 additive to the ammonia water, the additive is a mixture of polyacrylic acid amide and polyethylene glycol mixed in a ratio of 1:2, after stirring evenly, slowly add the zirconium oxychloride solution to the ammonia water for reaction, continue stirring, and control The reaction temperature is 30°C. When the pH value of the reaction solution is detected to be 9, the feeding is stopped immediately, and the obtained zirconium hydroxide hydrosol is sent to a filter press and washed with water. When the chloride ion content in the washing water is less than 120ppm At the same time, take out the zirconium hydroxide filter cake and put it into the alcohol liquid tank and wash i...

Embodiment 3

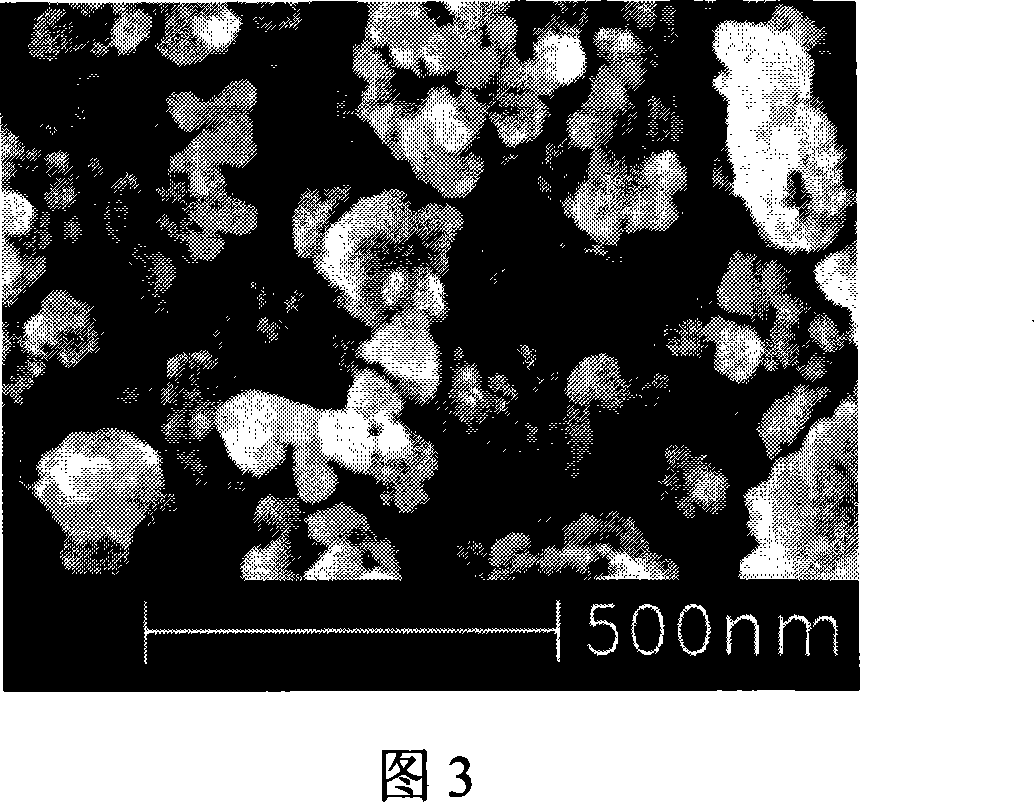

[0021] Embodiment 3: take by weighing zirconium oxychloride 170g and dissolve in deionized water, be mixed with 0.4mol / L zirconium oxychloride solution for subsequent use; Pass 60g liquid ammonia into 940ml deionized water, be mixed with the ammoniacal liquor that concentration is 6%, then add to Add 1.5g of additive to the ammonia water, the additive is a mixture of polyacrylic acid amide and polyethylene glycol mixed in a ratio of 1:1.8, after stirring evenly, slowly add the zirconium oxychloride solution into the ammonia water to react, continue stirring, and control The reaction temperature is 27°C. When the pH value of the reaction solution is detected to be 9, the feeding is stopped immediately, and the obtained zirconium hydroxide hydrosol is sent to a filter press and washed with water. When the chloride ion content in the washing water is less than 120ppm At the same time, take out the zirconium hydroxide filter cake and put it into the alcohol liquid tank and wash it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com