Method for simple and rapid preparation of hydrogel bilayer film with high adhesion acting force

A hydrogel single-layer, high-adhesion technology, applied in the field of functional polymer materials, can solve the problems of complex preparation process and low adhesive energy, and achieve high adhesive strength, simple preparation method, excellent strength and elongation at break The effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

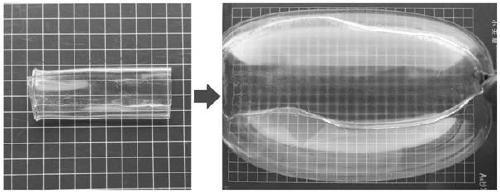

[0035] (1) In a 20mL glass bottle, disperse 1.5g of aluminum hydroxide sol with a concentration of 16.88% in 9.0g of pH=6 MES buffer evenly, then wrap the reaction bottle with tinfoil at room temperature, and stir for 30min by bubbling with nitrogen to remove Dissolved oxygen, then added monomers 0.217g acrylic acid (AA) and 2.17g N,N-dimethylacrylamide (DMAA) and 30mg photoinitiator 2-hydroxy-4'-(2-hydroxyethoxy)- 2-Methyl propiophenone, continue stirring with nitrogen for 15 minutes, then vacuumize for 20 minutes to remove residual gas, and finally inject the solution into a specific glass mold filled with nitrogen, and put the mold into an ultraviolet crosslinking instrument, at a wavelength of 365nm After irradiating with ultraviolet light for 60 minutes, the photoinitiator initiates free radical polymerization of the monomer, and finally obtains ADAgels, whose morphology is as follows figure 1 shown.

[0036] (2) Add and weigh 0.107g of morpholineethanesulfonic acid into...

Embodiment 2

[0042] (1) In a 20mL glass bottle, disperse 0.3g of aluminum hydroxide sol with a concentration of 16.88% in 10.2g of pH=6 MES buffer evenly, then wrap the reaction bottle with tinfoil at room temperature, and stir with nitrogen gas for 30min to remove Dissolved oxygen, add monomer 0.145g AA and 1.285g acrylamide (AM) and stir rapidly under nitrogen gas at room temperature for 15min, then evacuate for 20min to remove residual gas, put the mixed solution in an ice-water bath to cool for a period of time and sonicate for 10min , and then under the protection of ice bath and nitrogen environment, 8 μL of catalyst TEMED and 0.02 g of initiator potassium persulfate were added successively, and after stirring for 1 min, the solution was quickly injected into a specific glass mold filled with nitrogen, sealed and polymerized at room temperature for 48 hours, and then heated The initiator initiates the radical polymerization reaction of the monomer, and finally obtains AMAgels.

[004...

Embodiment 3

[0047] (1) In a 20mL glass bottle, disperse 1.69g of 15% zirconium hydroxide sol in 8.31g of pH=6 MES buffer evenly, then wrap the reaction bottle with tinfoil at room temperature, and stir for 30min by bubbling nitrogen to remove Dissolved oxygen, then add monomer 0.217g AA and 2.17g DMAA and 30mg photoinitiator 2-methyl-1-[4-methylthiophenyl]-2-morpholinyl-1-acetone, continue nitrogen Stir for 15 minutes, then evacuate for 20 minutes to remove the residual gas, and finally inject the solution into a specific glass mold filled with nitrogen, put the mold into an ultraviolet crosslinking instrument, and irradiate it with ultraviolet light with a wavelength of 365nm for 60 minutes. The monomer undergoes free radical polymerization reaction, and finally ADZ gels are obtained.

[0048] (2) Add and weigh 0.107g of morpholineethanesulfonic acid into 9.9mL of deionized water, stir well and then add 0.2g of chitosan, and adjust the pH to 6.0 with 1.0mol / L NaOH solution, take 2ml of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com