Method for purifying oil-containing waste water of catering and complete equipment thereof

A wastewater purification and treatment method technology, applied in the field of water treatment, can solve the problems of low treatment efficiency, troublesome membrane cleaning, large floor area, etc., and achieve the effect of saving maintenance costs, saving operating costs, and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The sources of the oily wastewater used in this example are: kitchen wastewater from hotels, hotels, canteens, holiday villages, scenic spots, and residential buildings; the impurities contained therein mainly include: food fiber, starch, animals and plants Fats, seasonings of all kinds, detergents and proteins.

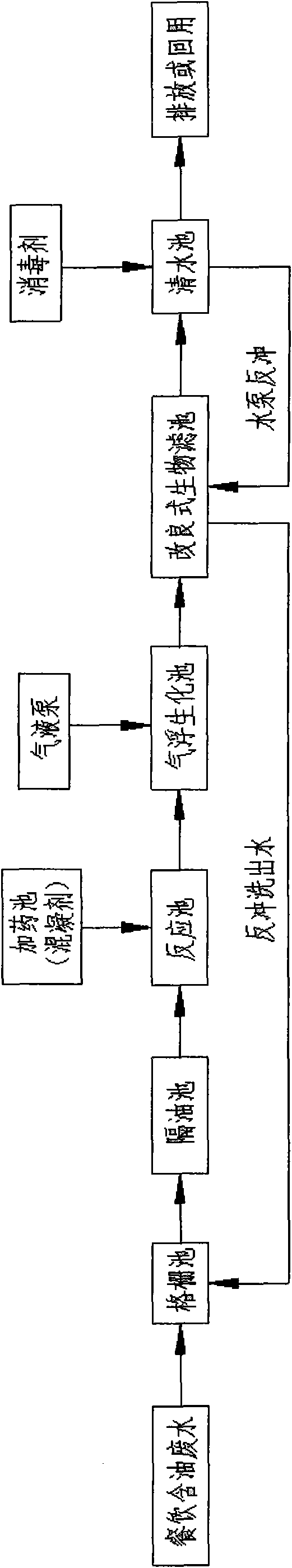

[0060] figure 1 It is a flow chart of the method for purification and treatment of oily wastewater from catering in this embodiment.

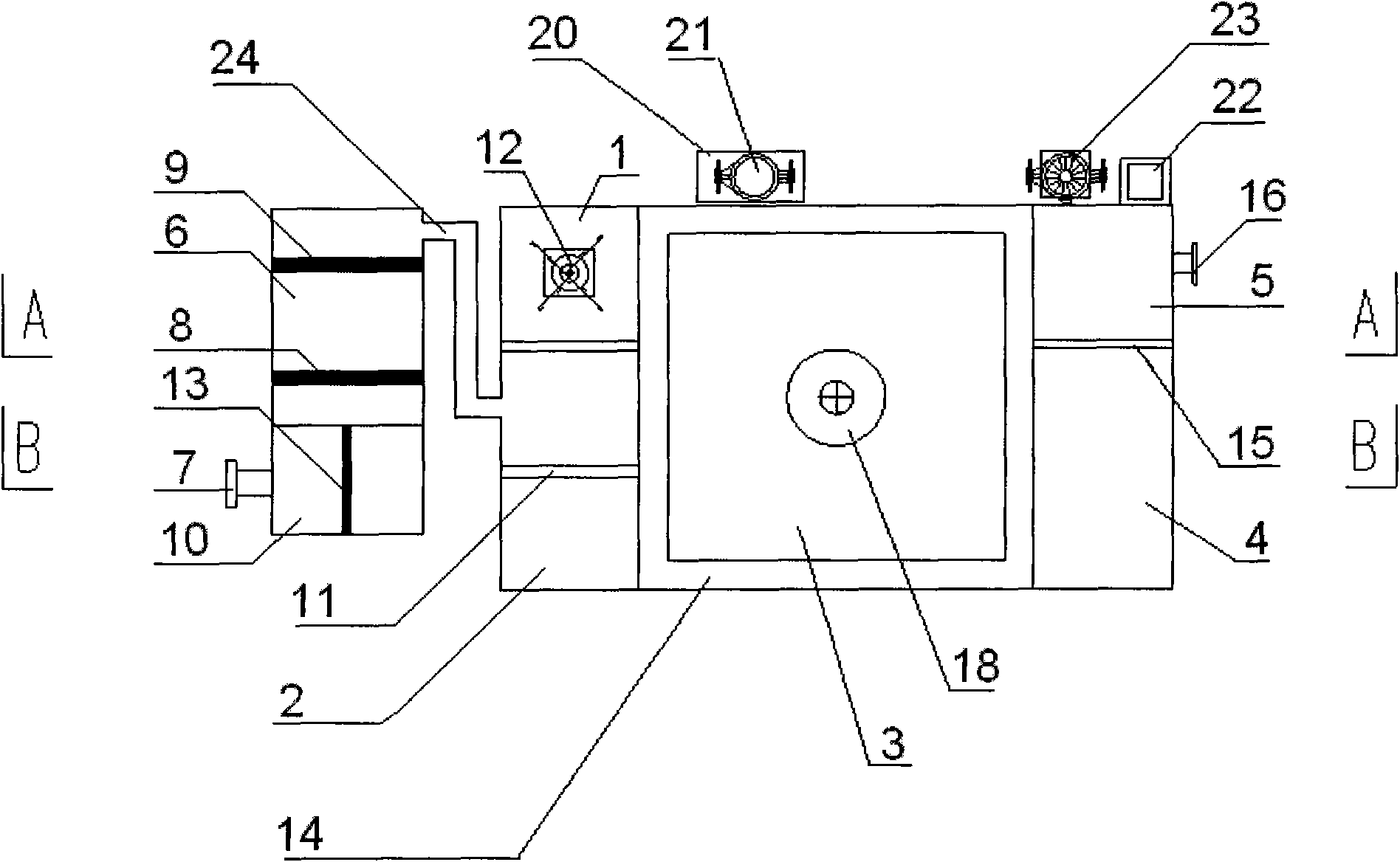

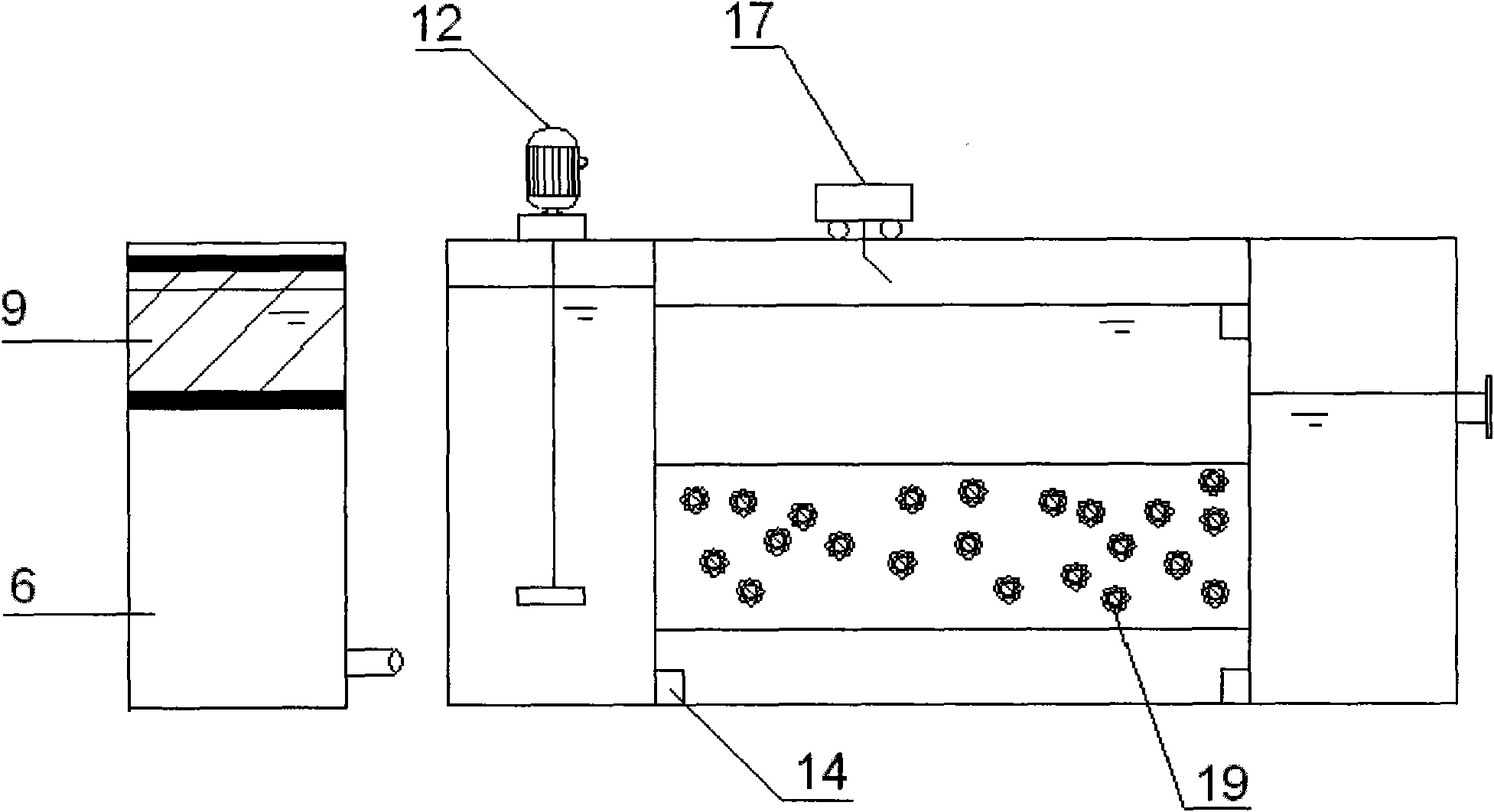

[0061] figure 2 It is a structural diagram of the complete set of equipment for purification and treatment of catering oily wastewater in this embodiment. The complete set of equipment for the treatment method of catering wastewater includes: dosing pool 1, reaction pool 2, air flotation biochemical pool 3, improved biological filter 4, clear water Pool 5, grease trap 6 and grille pool 10; wherein, the inside of grille pool 10 is provided with grille 13, and one side of grille pool 10 is provided with water inlet pipe 7, and...

Embodiment 2

[0084] The source of the catering oily wastewater used in this example and the impurities contained therein are the same as those in Example 1.

[0085] The method flow of purification treatment is:

[0086] 1) Mechanical oil separation: the oily waste water from food and beverages passes through the grid to remove suspended solids and impurities in the oily waste water, and then enters the grease trap for mechanical oil separation;

[0087] 2) Suspended matter coagulation treatment: the effluent after mechanical oil pollution separation enters the reaction tank, and the coagulant aluminum sulfate is added in the tank according to the dosing amount of 50mg / L, and after mechanical stirring, it enters the reaction tank and stays for 5 minutes to make the water body Most of the suspended solids and colloids form flocs, which is beneficial to the subsequent solid-liquid separation;

[0088] 3) Air flotation biochemical treatment: After the effluent after coagulation treatment com...

Embodiment 3

[0098] The components and proportions of the biological filter material in step 6) are: 30% of quartz sand; 30% of activated carbon; 40% of zeolite molecular sieve, and other processing steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com