Process method for treating coking wastewater

A technology for coking wastewater and treatment process, which is applied in the fields of metallurgical wastewater treatment, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of long biochemical treatment process, small pH range of micro-electrolysis, and poor shock load resistance. , to achieve the effect of strengthening the solid-liquid mixing effect, good effect and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

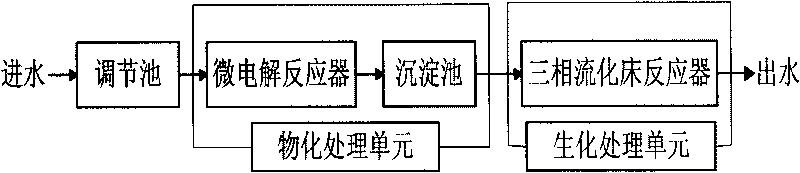

[0021] A coking wastewater treatment process method, including a physical and chemical treatment unit and a biochemical treatment unit; the coking wastewater enters the physical and chemical treatment unit after being regulated by a regulating tank, and the physical and chemical treatment unit is composed of a micro-electrolysis reactor (micro-electrolysis tower) and a sedimentation tank. The micro-electrolysis reaction The device is filled with scrap iron scraps, scrap copper scraps and light bulk materials; the effluent from the micro-electrolysis reactor enters the biochemical treatment unit after being settled in the sedimentation tank; the biochemical treatment unit is a three-phase fluidized bed reactor, and the three-phase The fluidized bed reactor is a filter-type internal circulation three-phase fluidized bed reactor. In the reactor, immobilized activated sludge pellets are used to achieve simultaneous denitrification and carbon removal. The phase forms an internal cir...

Embodiment 2

[0028] A coking wastewater treatment process The treatment process is the same as in Example 1. Among them, the influent COD, ammonia nitrogen, volatile phenol and chroma are about 3500mg / L, 200mg / L, 330 and 800 times respectively. The micro-electrolysis reactor is filled with industrial waste iron shavings, waste copper shavings and coke, and the mass ratio is 10:2:1. The inlet water pH of the micro-electrolysis reactor is 6.0, and the hydraulic retention time is 20 minutes. The three-phase fluidized bed reactor is filled with immobilized activated sludge pellets, and the filling volume accounts for 20% of the effective volume of the reactor. The filter area uses coke as the filter material, the height of the filter layer is 1.2m, the pH of the three-phase fluidized bed reactor feed water is 7.2, the dissolved oxygen is 6mg / L, the temperature is 32°C, and the hydraulic retention time is 20h. The COD of the effluent is 90-120mg / L, the ammonia nitrogen is 5-12mg / L, the volatil...

Embodiment 3

[0030] A coking wastewater treatment process The treatment process is the same as in Example 1. Among them, the influent COD, ammonia nitrogen, volatile phenol and chroma are about 3500mg / L, 200mg / L, 330 and 800 times respectively. The micro-electrolysis reactor is filled with industrial waste iron shavings, waste copper scraps and zeolite with a mass ratio of 10:2:1. The inlet water of the micro-electrolysis reactor has a pH of 4.0 and a hydraulic retention time of 45 minutes. The three-phase fluidized bed reactor is filled with immobilized activated sludge pellets, and the filling volume accounts for 30% of the effective volume of the reactor. The filter area uses coke as the filter material, the height of the filter layer is 1.2m, the pH of the feed water of the three-phase fluidized bed reactor is 7.8, the dissolved oxygen is 4mg / L, the temperature is 30°C, and the hydraulic retention time is 30h. The effect is the same as that of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com