Method for preparing titanium pigment by using titanium residues obtained by directly reducing titanium-iron oxide

A technology of oxides and titanium dioxide, applied in the direction of titanium oxide/hydroxide, titanium dioxide, process efficiency improvement, etc., can solve the problems of titanium dioxide-free process technology, removal of impurities, and inability to fully utilize titanium resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

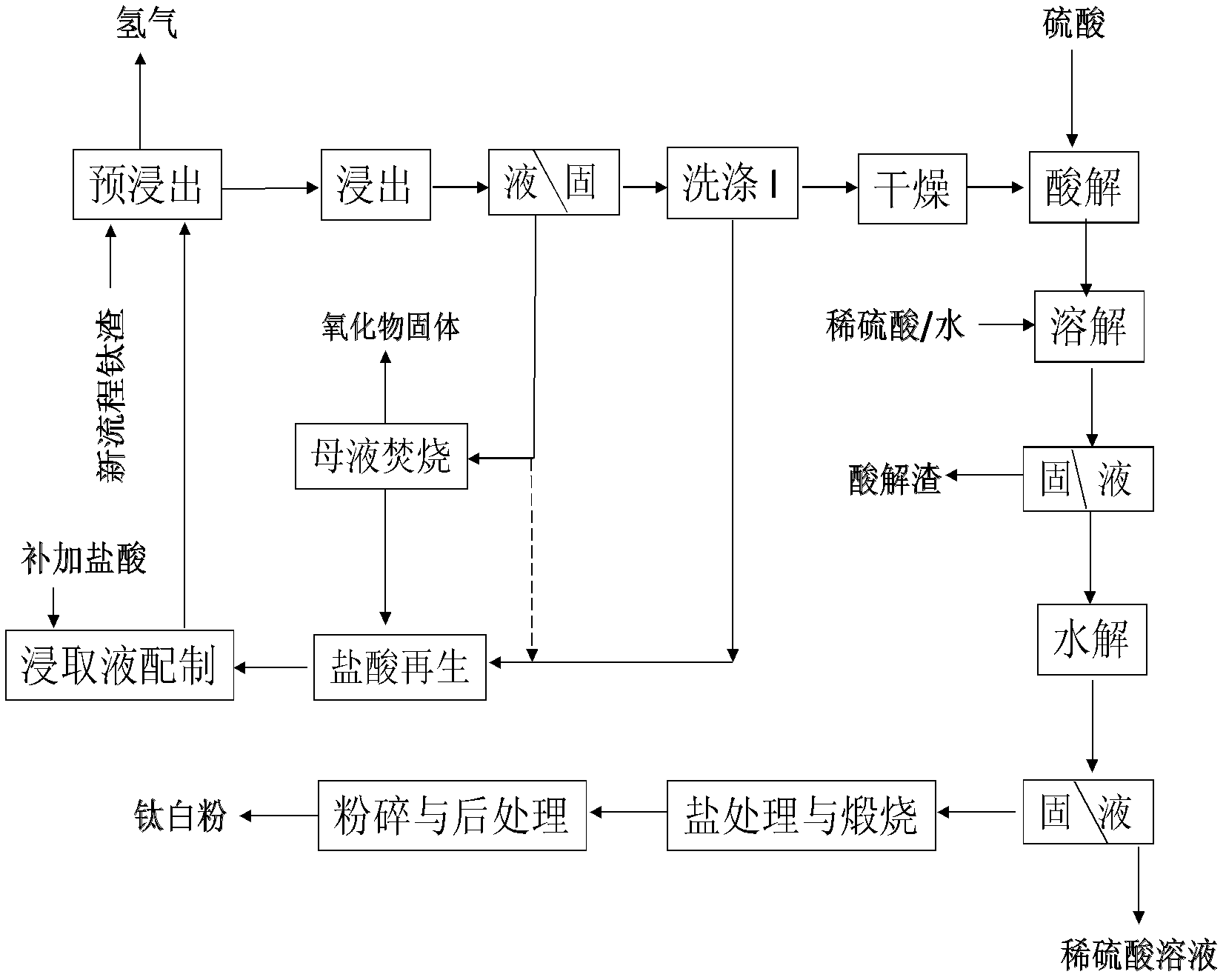

Method used

Image

Examples

Embodiment 1

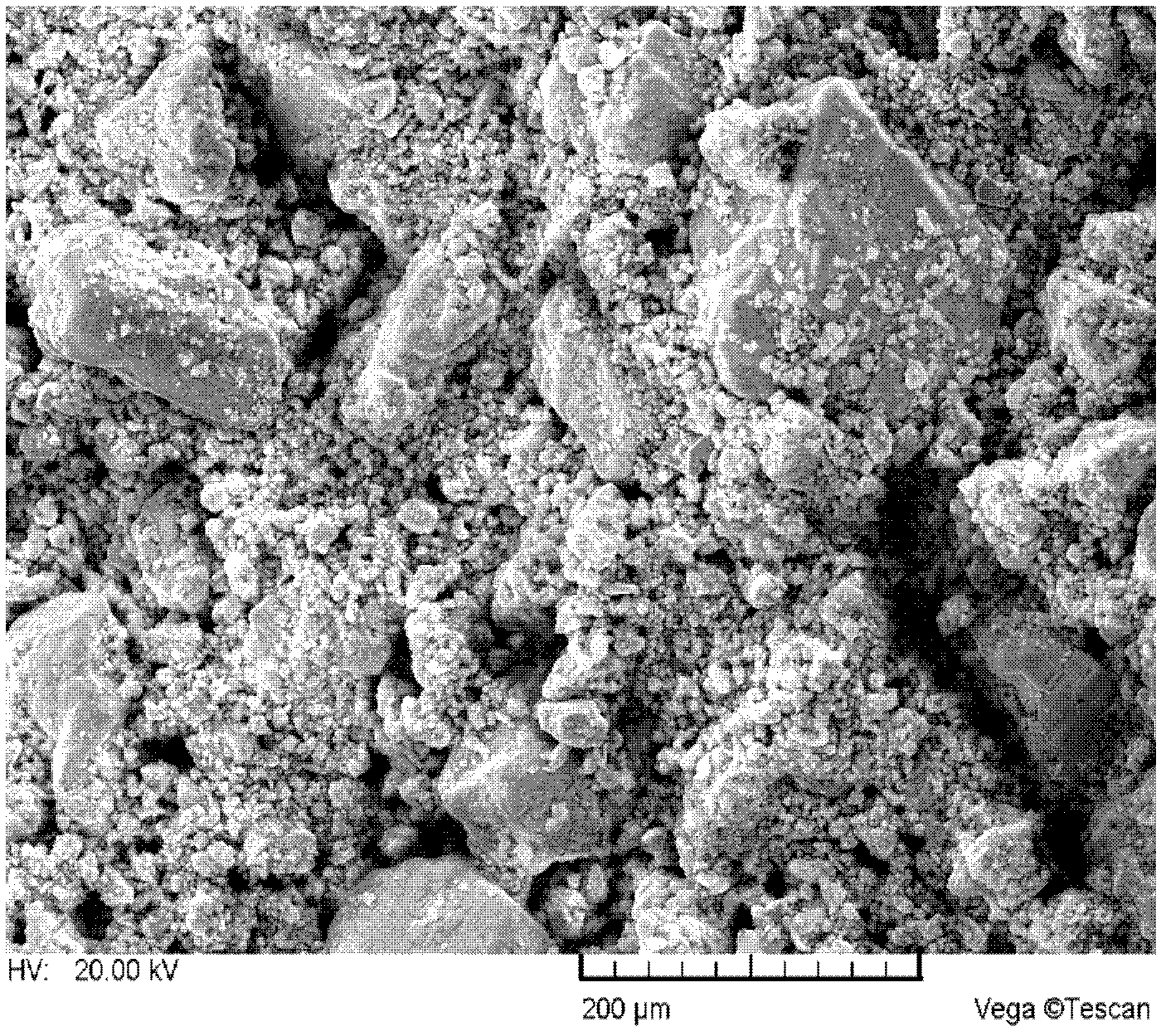

[0216] Example 1 Preparation of titanium-rich hydrochloric acid leaching slag by leaching and directly reducing titanium slag using pure dilute hydrochloric acid

[0217] 1. Measure 1.2 liters of 20% hydrochloric acid and pour it into a 2-liter glass;

[0218] 2. Weigh 600 grams of negative 50 mesh titanium slag purchased from the market by direct reduction electric furnace melting titanium slag—direct reduction new process titanium slag (1), pour it into a 2-liter glass cup and mix it with hydrochloric acid solution, and the slurry will automatically heat up to 92°C and stirred for 2 hours. This process is pre-soaking, which is mainly to leach the iron in the new process titanium slag-1 first, which is an exothermic reaction, so the temperature will automatically rise;

[0219] 3. Move to a 3-liter zirconium reaction tank and heat to about 140°C for pressure leaching;

[0220] 4. After two hours, stop heating and cool down to 80°C naturally;

[0221] 5. Rapidly filter the ...

Embodiment 2

[0226] Example 2 Preparation of titanium-rich hydrochloric acid leaching slag by using hydrochloric acid leaching solution to leach titanium slag from a new process of direct reduction

[0227] 1, prepare the leaching solution containing 18% hydrochloric acid with the leaching mother liquor of embodiment 1 and 32% new hydrochloric acid, this leaching solution is the hydrochloric acid composite system solution containing soluble chloride salts such as aluminum chloride, calcium chloride, magnesium chloride , Table 10 is the main components of the leaching solution. Measure 1.4 liters of this extract and pour it into a 2 liter glass;

[0228] Table 10 Example 2 Leaching Solution Main Component Analysis

[0229] the element

[0230] 2. Weigh 600g-50 mesh new process titanium slag-1, pour it into a 2-liter glass cup and mix it fully with the leaching solution, the slurry will automatically heat up to 91°C, and stir for 2 hours to pre-soak;

[0231] 3. Move to a 3-liter...

Embodiment 3

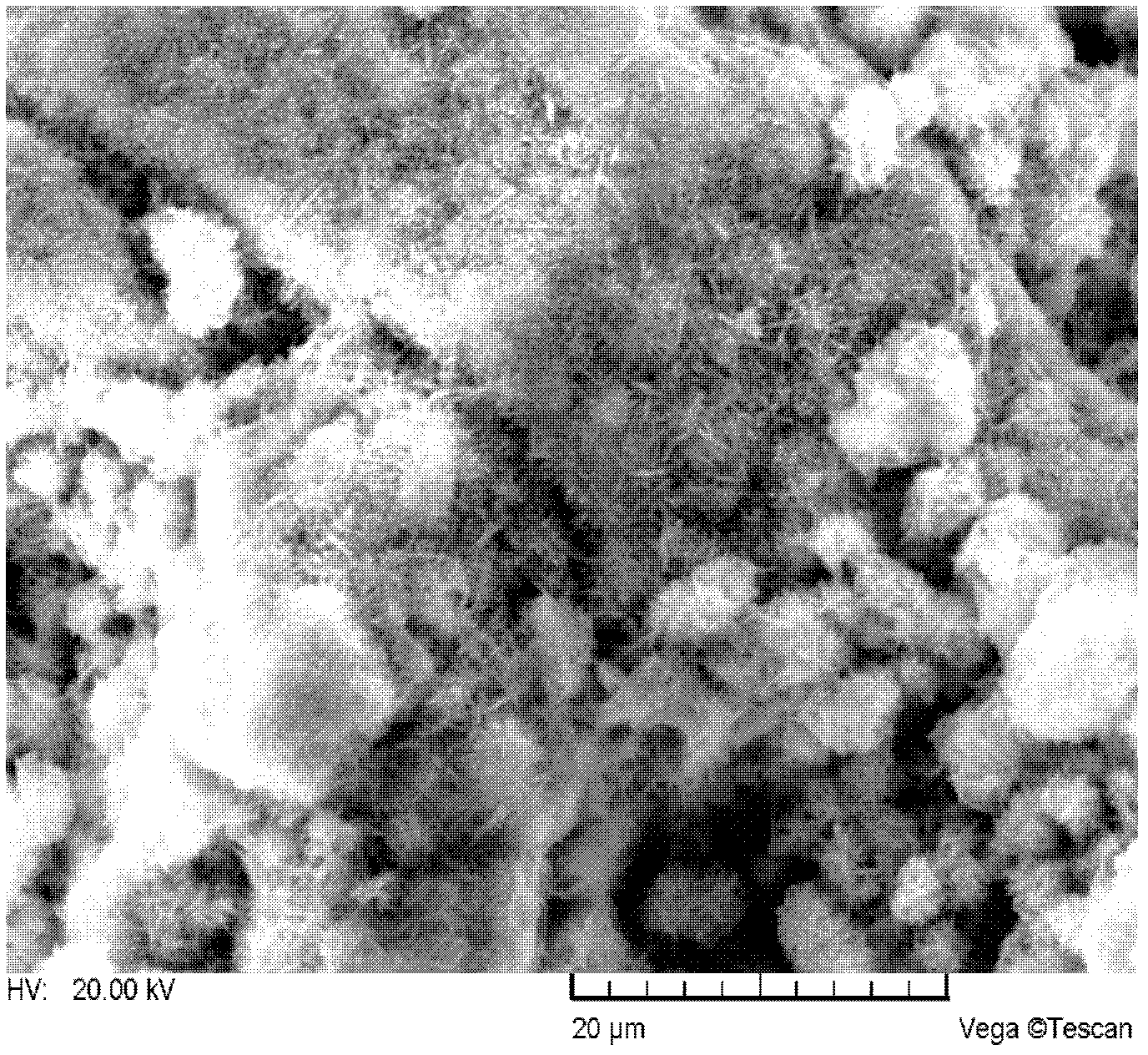

[0239] Example 3 Preparation of titanium-rich hydrochloric acid leaching slag using hydrochloric acid leaching solution to leach titanium slag from a new process of direct reduction

[0240] 1, prepare the leaching solution containing 18% hydrochloric acid with the leaching mother liquor of embodiment 1 and 32% new hydrochloric acid, this leaching solution is the hydrochloric acid composite system solution containing soluble chloride salts such as aluminum chloride, calcium chloride, magnesium chloride , measure 1.4 liters of the leaching solution, and pour it into a 2-liter glass;

[0241] 2. Weigh 600g-50 mesh new process titanium slag-2, pour it into a 2-liter glass cup and mix it fully with the leaching solution, the slurry is automatically heated to 80°C, and stirred for 2 hours to pre-soak;

[0242] 3. Move to a 3-liter zirconium reaction tank and heat to about 145°C for further leaching;

[0243] 4. After 2 hours, stop heating and cool naturally to 80°C;

[0244] 5. R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com