Ferro-manganese composite oxide catalyst and preparation method thereof

A technology of composite oxides and catalysts, applied in the field of water treatment, can solve the problems of secondary pollution of water bodies, large quantities, and increased treatment costs, and achieve the effects of simplified treatment, simple process flow, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of Fe-Mn Composite Oxide Catalyst

[0037] Preparation steps:

[0038] 1) Take 100g of polyvinyl alcohol and add 10L of distilled water, heat and stir to dissolve, and cool to room temperature to obtain a polyvinyl alcohol solution.

[0039] 2) Add the polyvinyl alcohol solution and the sodium dodecylbenzenesulfonate solution with a molar concentration of 0.2mol / L to the ferrous sulfate solution with a molar concentration of 1.2mol / L, stir magnetically for 2min, and then add a solution with a molar concentration of 2.5mol / L. The sodium carbonate solution of L, makes mixed solution; Polyvinyl alcohol solution: sodium dodecylbenzene sulfonate solution: ferrous sulfate solution: sodium carbonate solution volume ratio is 5:20:30:8;

[0040] 3) Add natural ferromanganese ore to the mixed solution prepared in step 2), stir and react for 4 hours, add 300 g of natural ferromanganese ore per liter of mixed solution; separate the solid particles after the reaction, d...

Embodiment 2

[0042] With the preparation method of the iron-manganese composite oxide catalyst described in embodiment 1, the difference is:

[0043] In step 3), the dried solid particles were calcined at 550° C. for 3 hours to obtain an iron-manganese composite oxide catalyst, which was designated as material b.

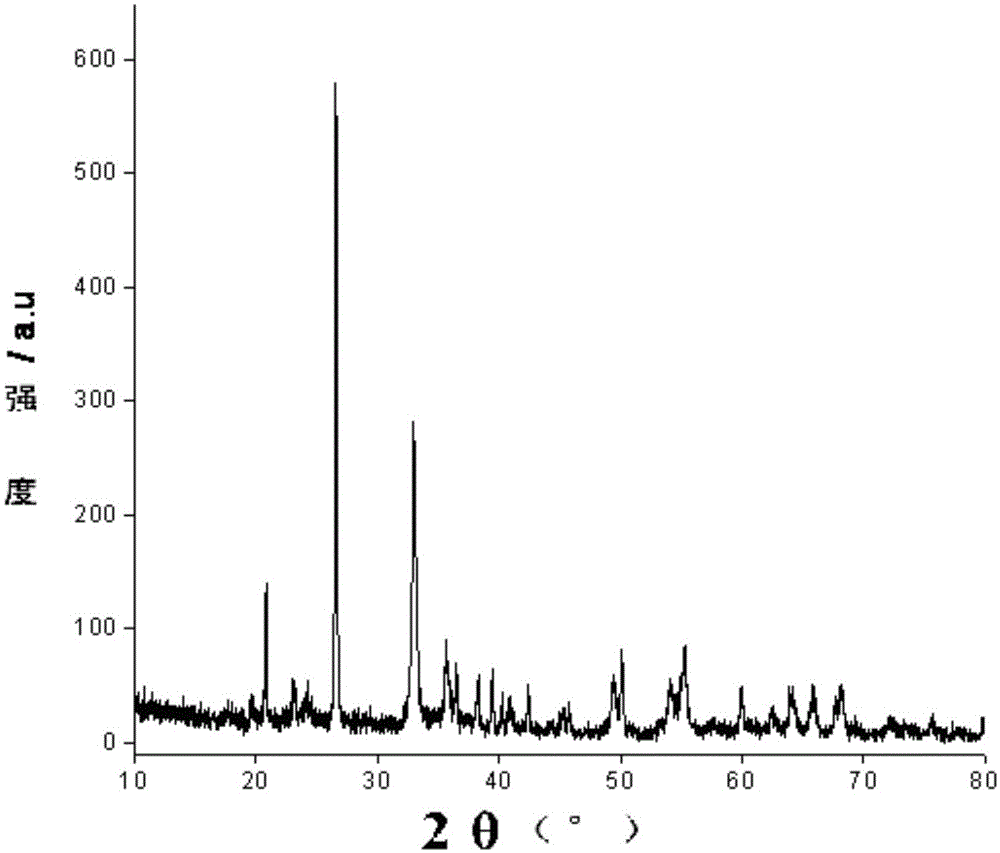

[0044] Material b was characterized by XRD using Cu-Kα rays, and the obtained XRD pattern is as follows figure 1 As shown, it shows SiO at 2θ of 20.8°, 26.6°, 36.5°, 36.5°, 40°, 50°, 60° 2 Characteristic peaks; at 2θ of 23°, 33°, 38.3°, 55.3° show α-Mn 2 o 3 Characteristic peaks; at 2θ of 24°, 33.1°, 35.6°, 49.3°, 54° show α-Fe 2 o 3 Characteristic peaks.

[0045] According to fluorescence spectrum analysis, the above-mentioned iron-chromium composite oxide SiO 2 The content is about 15%, α-Mn 2 o 3The content is about 30-50%, α-Fe 2 o 3 The content is about 20-40%, and the trace elements are about 0.1%.

Embodiment 3

[0047] With the preparation method of the iron-manganese composite oxide catalyst described in embodiment 1, the difference is:

[0048] In step 3), the dried solid particles were calcined at 650° C. for 3 hours to obtain an iron-manganese composite oxide catalyst, which was designated as material c.

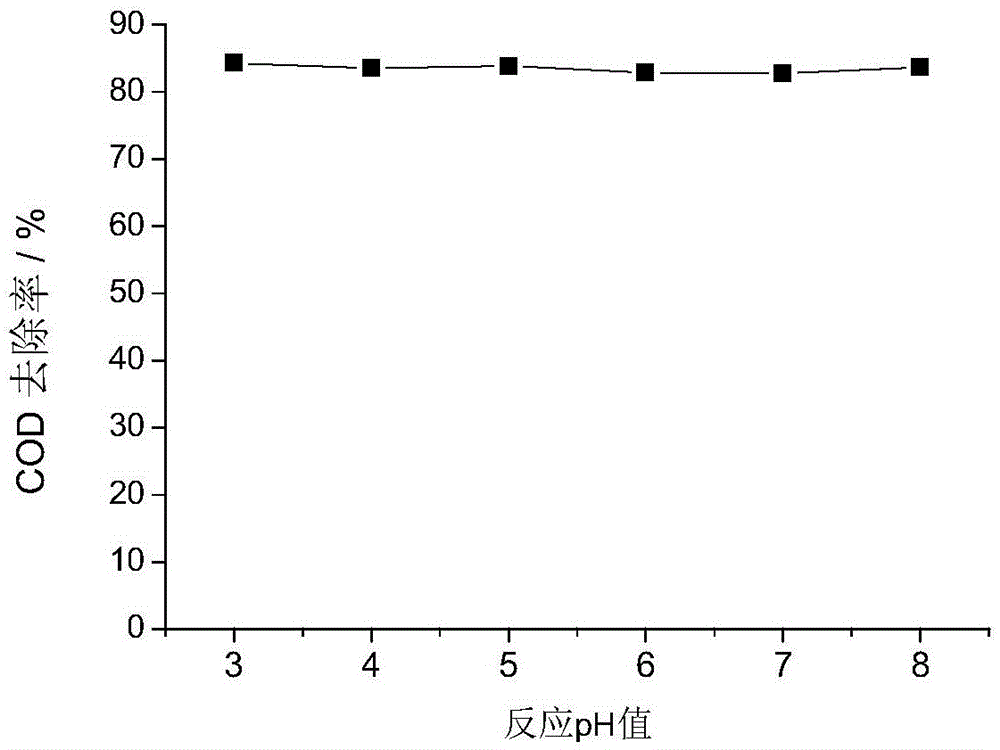

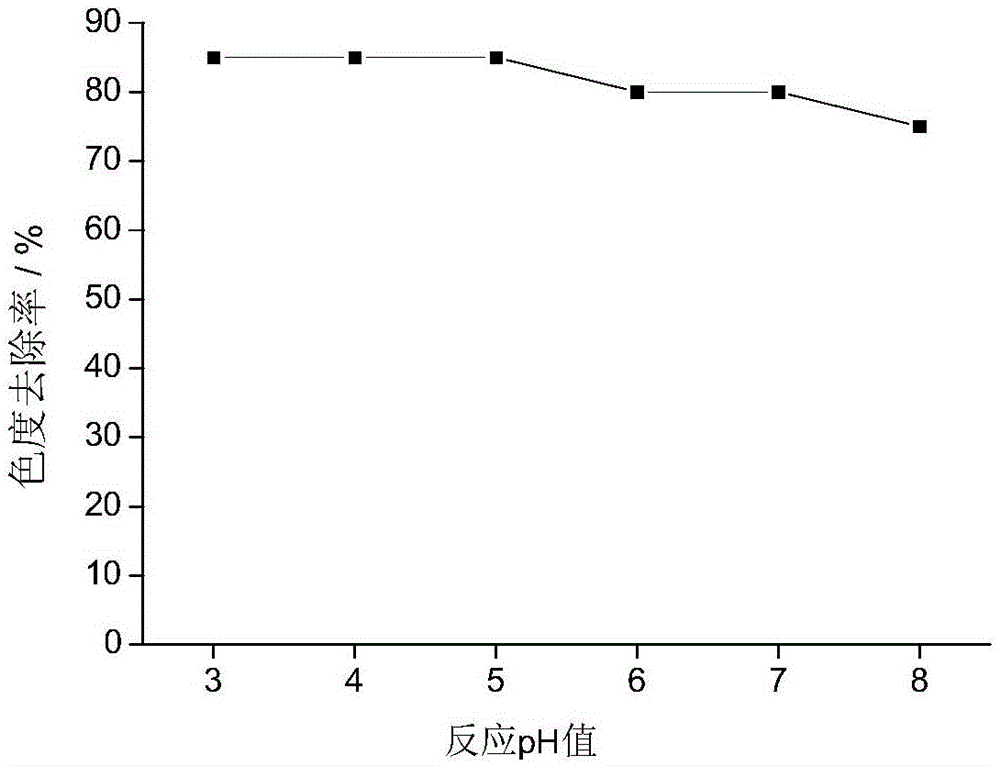

[0049] The catalyst of the present invention is applicable to a wide range of pH. Within the range of pH 3-8, the treatment effects of the iron-manganese composite oxide particles of the present invention on COD, chroma and ss can be seen in the pH range. Figure 2-Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com