Device and method for alternating reinforced water injection permeation strengthening and wetting of low-porosity coal seam

A porosity and coal seam technology, applied in safety devices, earthwork drilling, mining fluids, etc., can solve problems such as coal seam water injection difficulties, achieve the effect of increasing coal porosity and permeability, and improving water injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

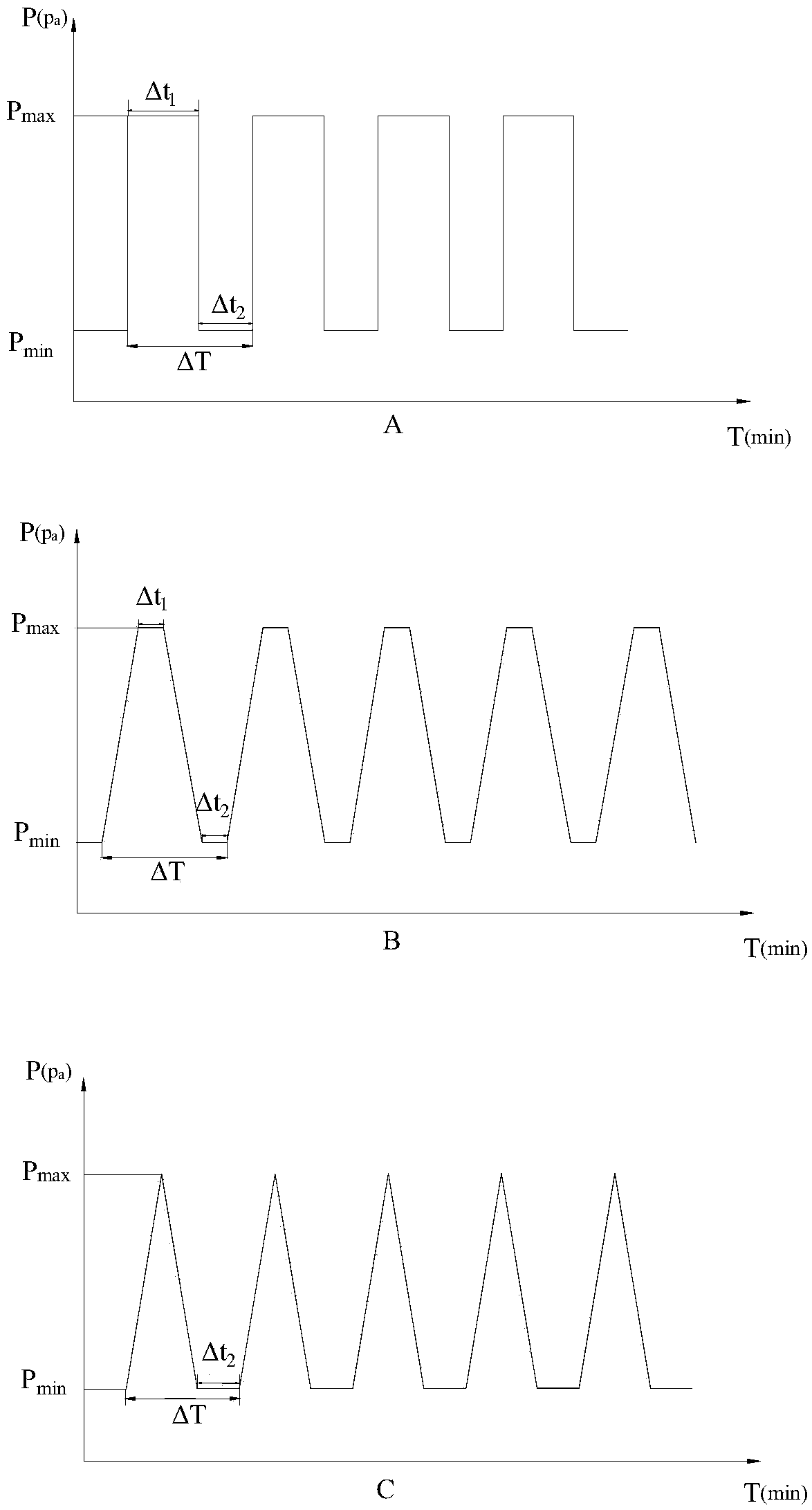

[0043] The waveform of alternating water pressure action is a rectangular wave, see figure 2 (A) shown. P max is the maximum water injection pressure; P min is the minimum water injection pressure; ΔT is the alternating water injection cycle; Δt 1 0~30min; Δt 2 10 to 20 minutes.

Embodiment 2

[0045] The waveform of alternating water pressure action is trapezoidal wave, see figure 2 (B) shown. P max is the maximum water injection pressure; P min is the minimum water injection pressure; ΔT is the alternating water injection cycle; Δt 1 0~30min; Δt 2 10 to 20 minutes.

Embodiment 3

[0047] The waveform of alternating water pressure action is a triangular wave, see figure 2 (C) shown. P max is the maximum water injection pressure; P min is the minimum water injection pressure; ΔT is the alternating water injection cycle; Δt 1 0~30min; Δt 2 10 to 20 minutes.

[0048] Under the impact of high and low alternating circulating water pressure, the coal body will produce obvious fatigue damage, increase the pores and cracks of the alternately strengthened water injection coal body, and then make the pressure water penetrate into the coal matrix along the cracks and pores, and finally achieve the improvement of the coal seam. The purpose of water injection, wetting, dust suppression and anti-scour effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com