Long-distance deep hole water injection process for coal bed of fully mechanized work surface

A working face, long-distance technology, used in safety devices, mining equipment, earth-moving drilling, etc., can solve problems such as low production efficiency, impact on production, and physical harm to safety production operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

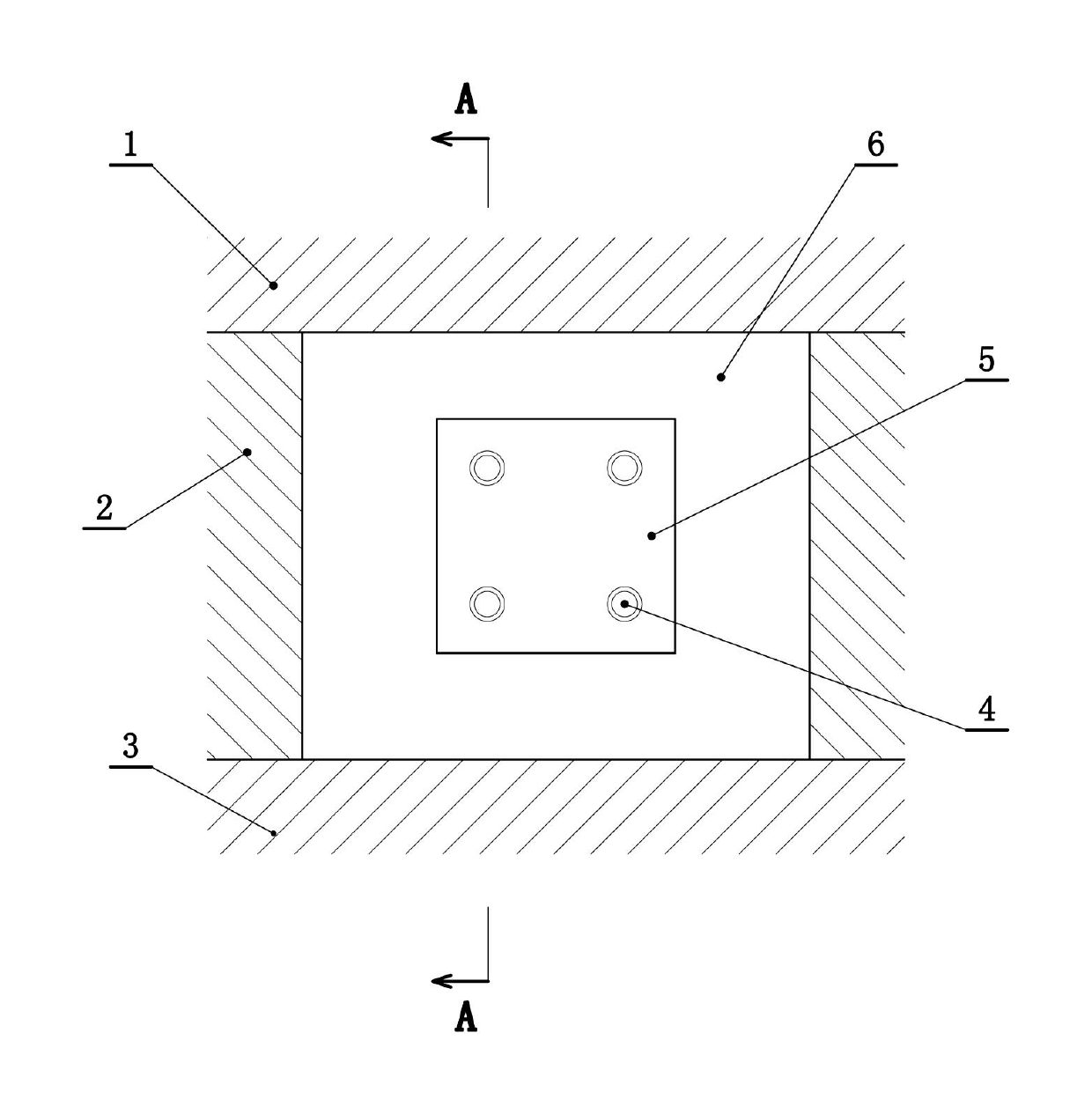

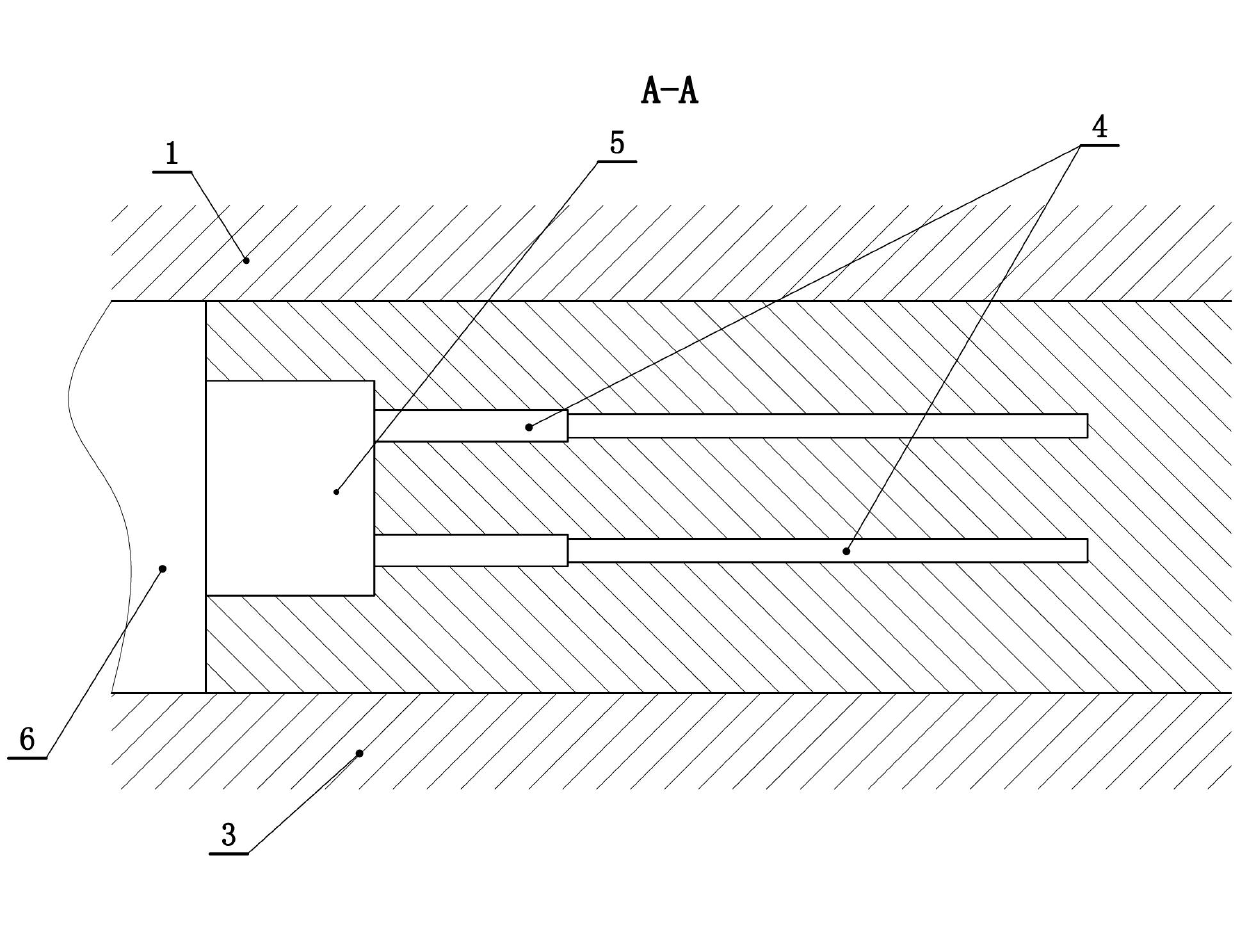

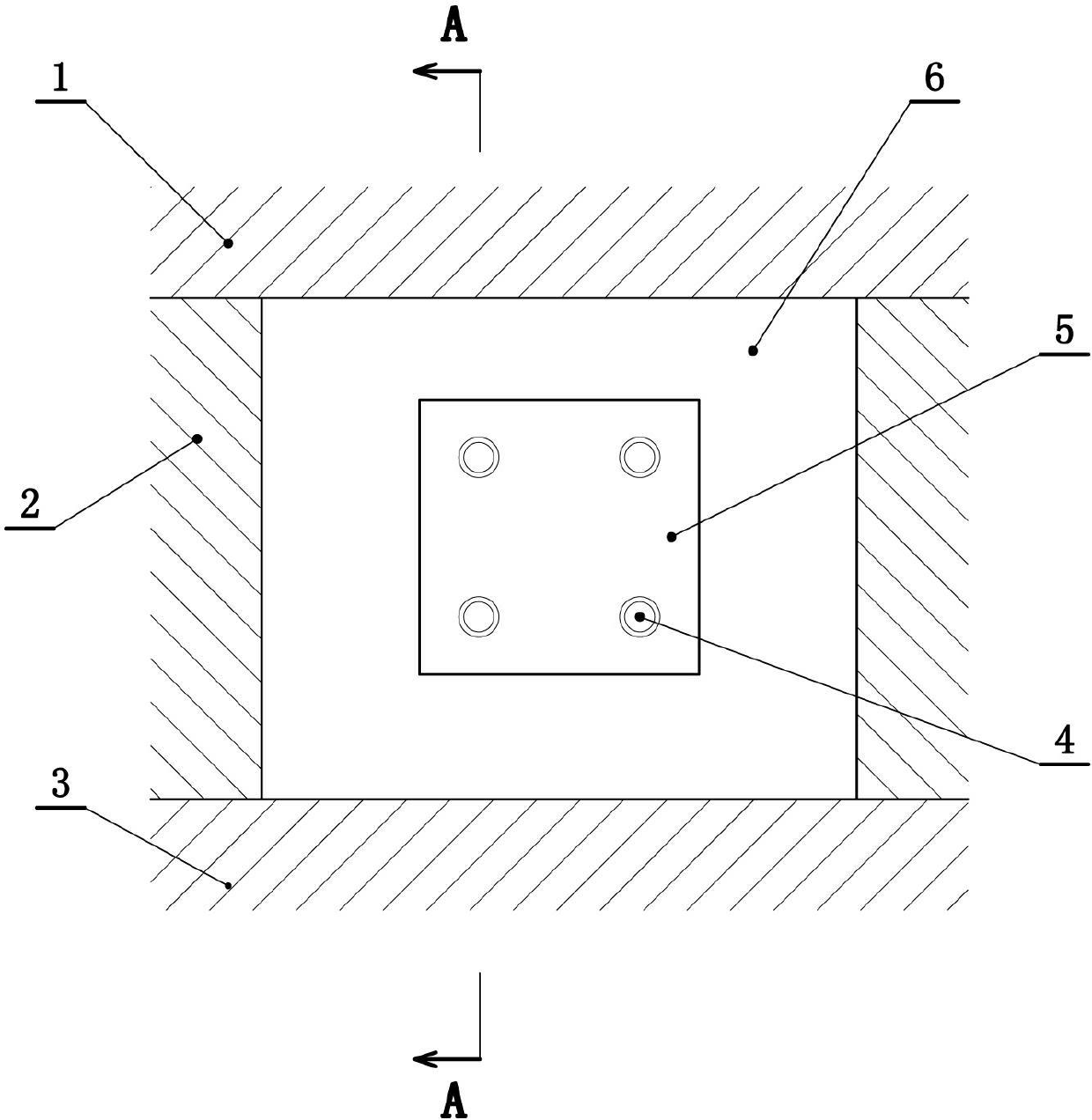

[0017] A long-distance deep-hole water injection technology for coal seams in fully mechanized excavation working faces, such as figure 1 , figure 2 shown, including the following steps:

[0018] a. A drilling rig nest is drilled ahead of the coal wall at the construction site of the excavation face;

[0019] b. Drill holes along the direction of roadway extension in the drilling rig nest;

[0020] c. Use a hole sealer to seal the borehole. The hole sealer includes a high-pressure rubber expansion tube, a safety valve and a quick connector; insert the hole sealer completely into the borehole so that the waterway at the job site is connected to the hole sealer, and the high-pressure glue expands. The tube is expanded under water pressure to seal the hole. Drill four holes in the step b, wherein the upper two holes are 1 / 3 of the roadway height fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com