A carbon fuel cell coal-based fuel combined processing device and processing method thereof

A combined processing and fuel cell technology, applied in fuel cells, fuels, solid fuels, etc., can solve the problems of increasing the cost of carbon fuel cells, destroying the activity of cathode and anode, and complicated steps, so as to facilitate the electrochemical reaction of the anode and improve the microstructure , The effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

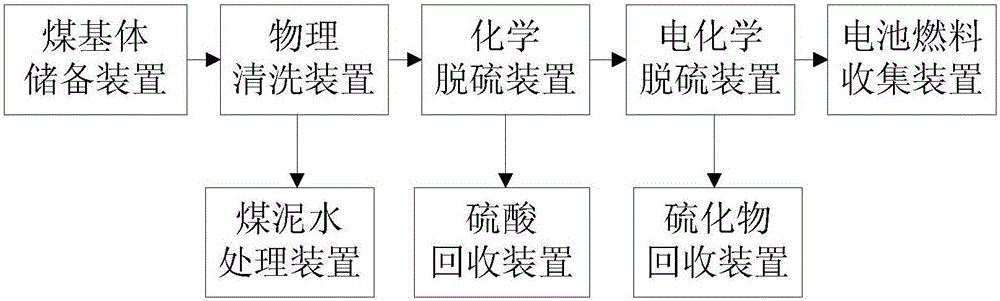

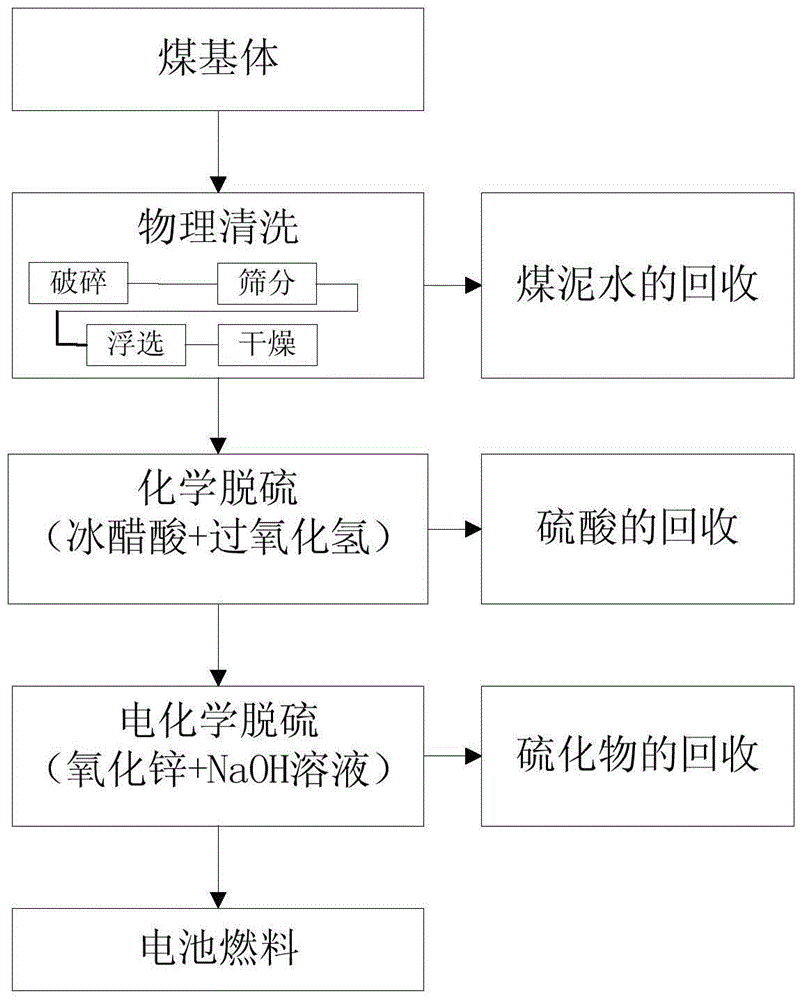

[0039] like figure 1 As shown, the carbon fuel cell coal-based fuel joint processing device in this embodiment includes a coal matrix storage device, a physical cleaning device, a chemical desulfurization device, an electrochemical desulfurization device, a battery fuel collection device, a coal slime water treatment device, a sulfuric acid recovery device and a vulcanization device. Material recovery device; wherein, the coal matrix is stored in the coal matrix storage device, and the coal matrix storage device is connected to the physical cleaning device through the transmission pipeline; the physical cleaning device is connected to the chemical desulfurization device through the transmission pipeline, and the bottom of the physical cleaning device is connected to the slime water treatment device The chemical desulfurization device is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com