Coal bed gas yield forecasting method

A technology for production forecasting and coalbed methane, which is applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problem of reduced permeability, no consideration of the influence of coal pulverized plugging permeability, lack of coal fracture compression coefficient and coal volume shrinkage coefficient Comprehensive improvement and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to make the object, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

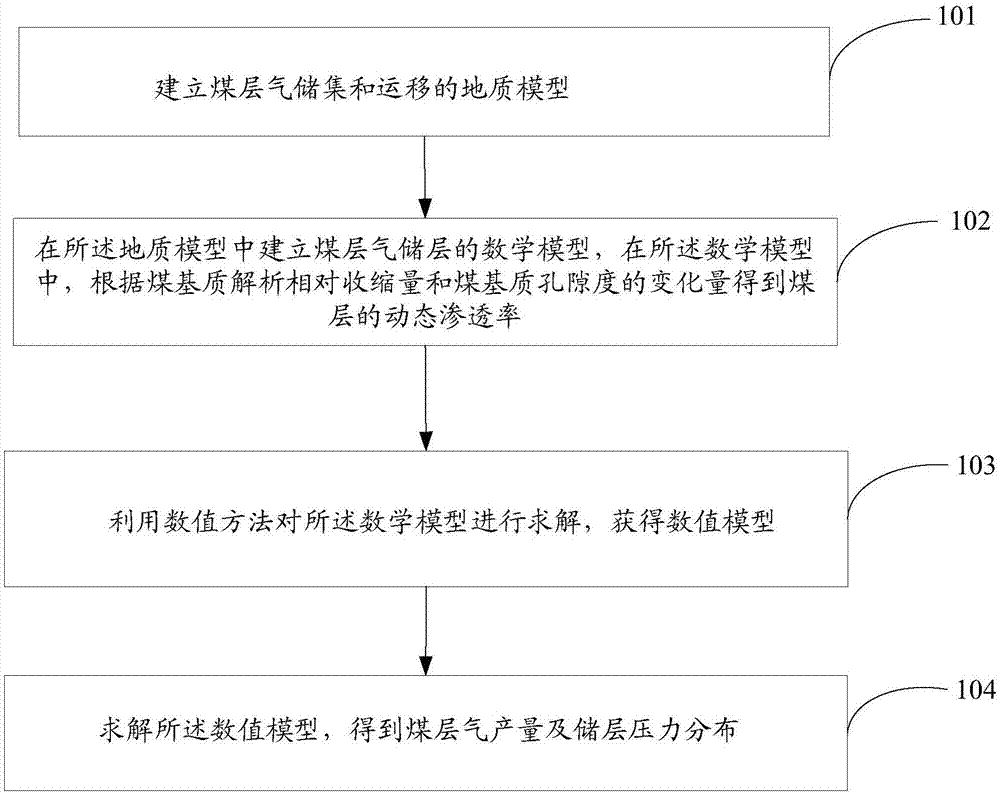

[0070] refer to figure 1 , a method for predicting coalbed methane production according to an embodiment of the present invention, comprising the steps of:

[0071] Step 101: Establish a geological model for coalbed methane storage and migration;

[0072] Specifically, according to the actual situation of the studied coalbed methane reservoir, construct the following figure 1 The two-dimensional geological model shown, input relevant parameters, the relevant parameters include grid step size, reservoir thickness h, porosity φ and permeability K o and other geological parame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com