Method for strengthening oxidative desulfurization and deashing of high-sulfur coal by coupling effect of electric field and pyrolusite

A technology for oxidative desulfurization and pyrolusite is applied in the field of pre-combustion desulfurization of coal, which can solve the problems of reducing coal quality, high cost, and strong reaction conditions, and achieve the effects of improving coal quality, high added value and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

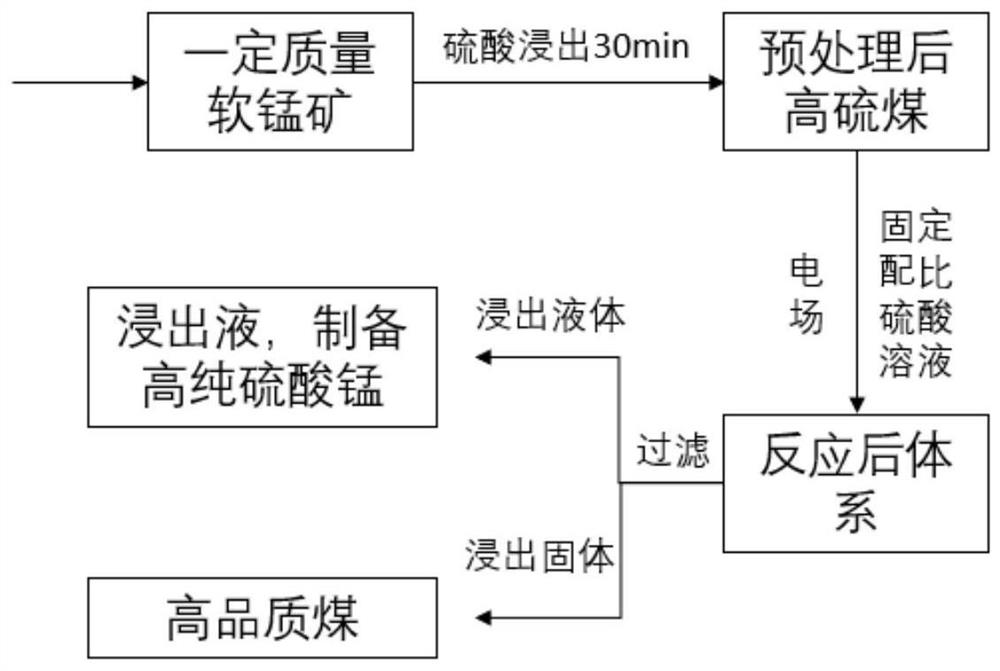

[0034] A method for strengthening the oxidative desulfurization and deashing of high-sulfur coal through the coupled action of an electric field and pyrolusite, specifically comprising the following steps:

[0035] (1) Pretreatment steps of raw coal:

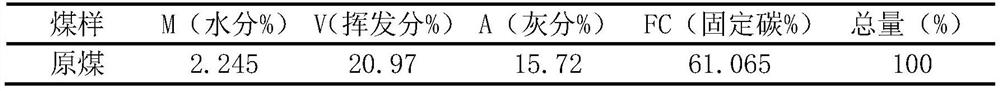

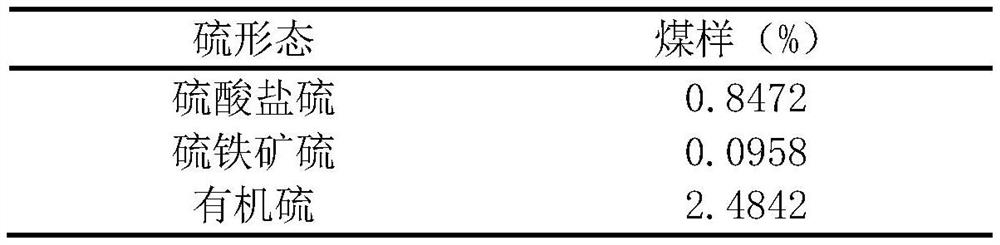

[0036] After the coal sample is dried, it is sent to a grinding or ball mill to crush it to a certain particle size, and the flotation method is used to adopt different pretreatment methods according to the flotation results, and the raw coal and the pretreated coal sample are subjected to industrial analysis, elemental analysis, total sulfur content, organic sulfur content, inorganic sulfur content (sulphate sulfur, pyrite sulfur);

[0037] According to the pretreatment scheme, scheme B was used for pretreatment in this experiment. Under the condition of 60°C, 5mol / L hydrochloric acid was used for acid leaching treatment of high-sulfur raw coal powder to be treated for 6h, and washed with a large amount of deionized water until...

Embodiment 2

[0050] A method for strengthening the oxidative desulfurization and deashing of high-sulfur coal through the coupled action of an electric field and pyrolusite, specifically comprising the following steps:

[0051] (1) Pretreatment steps of raw coal:

[0052] After the coal sample is dried, it is sent to a grinding or ball mill to crush it to a certain particle size, and the flotation method is used to adopt different pretreatment methods according to the flotation results, and the raw coal and the pretreated coal sample are subjected to industrial analysis, elemental analysis, total sulfur content, organic sulfur content, inorganic sulfur content (sulphate sulfur, pyrite sulfur);

[0053] According to the pretreatment plan, plan A was used in this experiment for pretreatment. Under the condition of 60°C, 5 mol / L hydrochloric acid was used to acid-leach the high-sulfur raw coal powder to be treated for 6 hours, and then washed with a large amount of deionized water until neutr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com