Device and method for detecting diffusion coefficient of coal bed gas in coal matrix

A diffusion coefficient and coalbed methane technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of destroying the space structure of coal matrix, and the large difference between the detection results and the diffusion coefficient of coalbed methane, and achieve the effect of close diffusion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

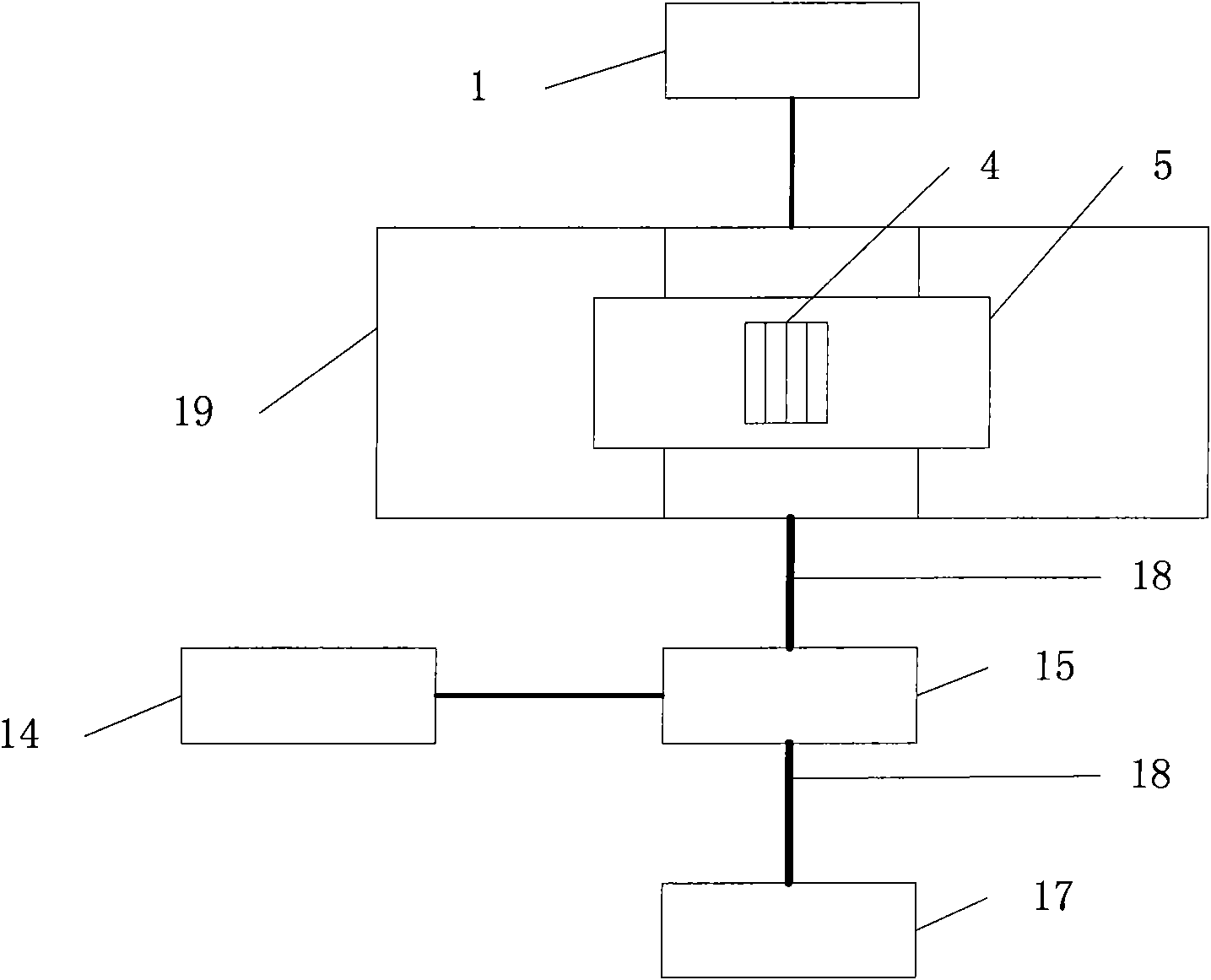

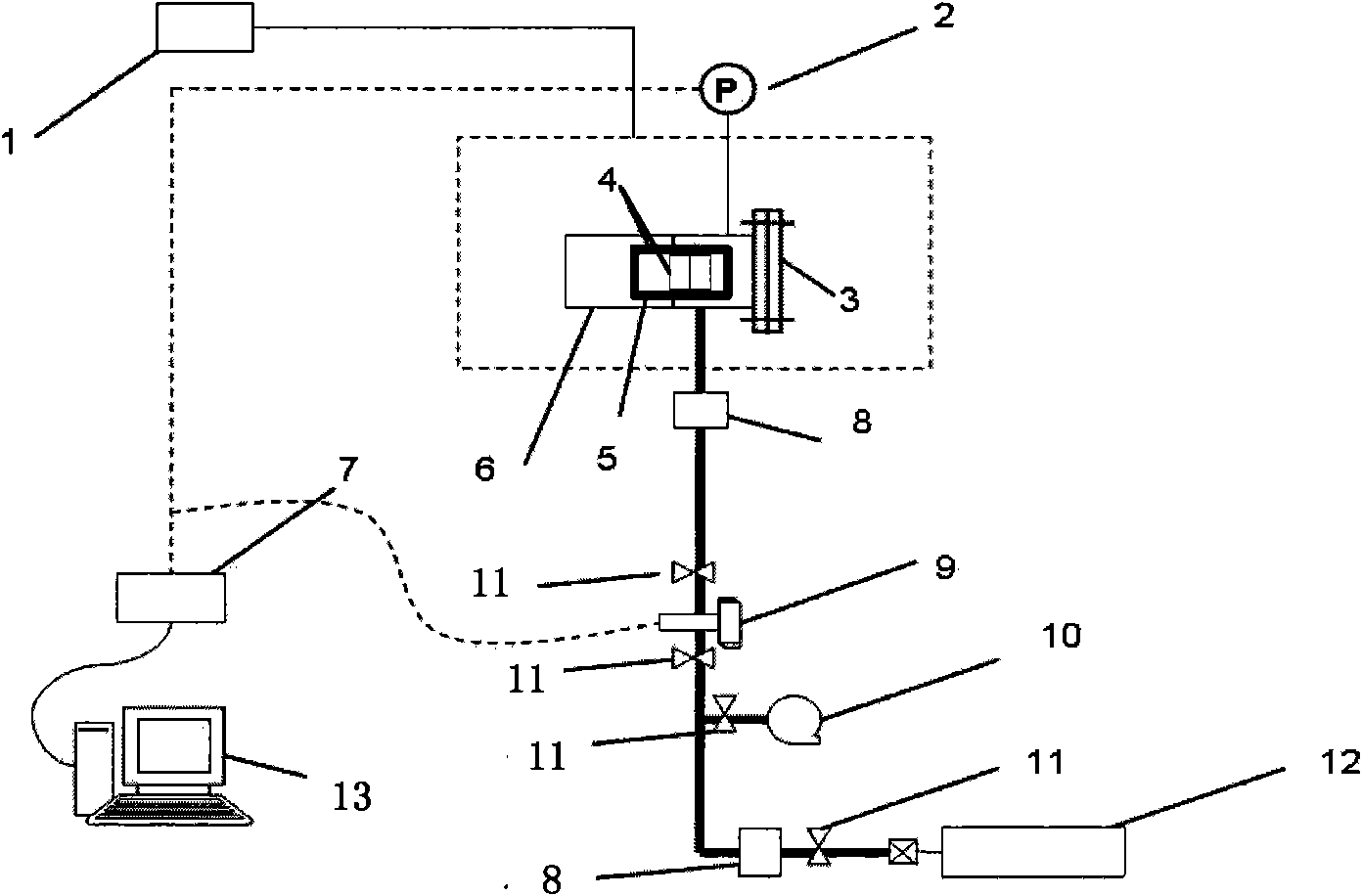

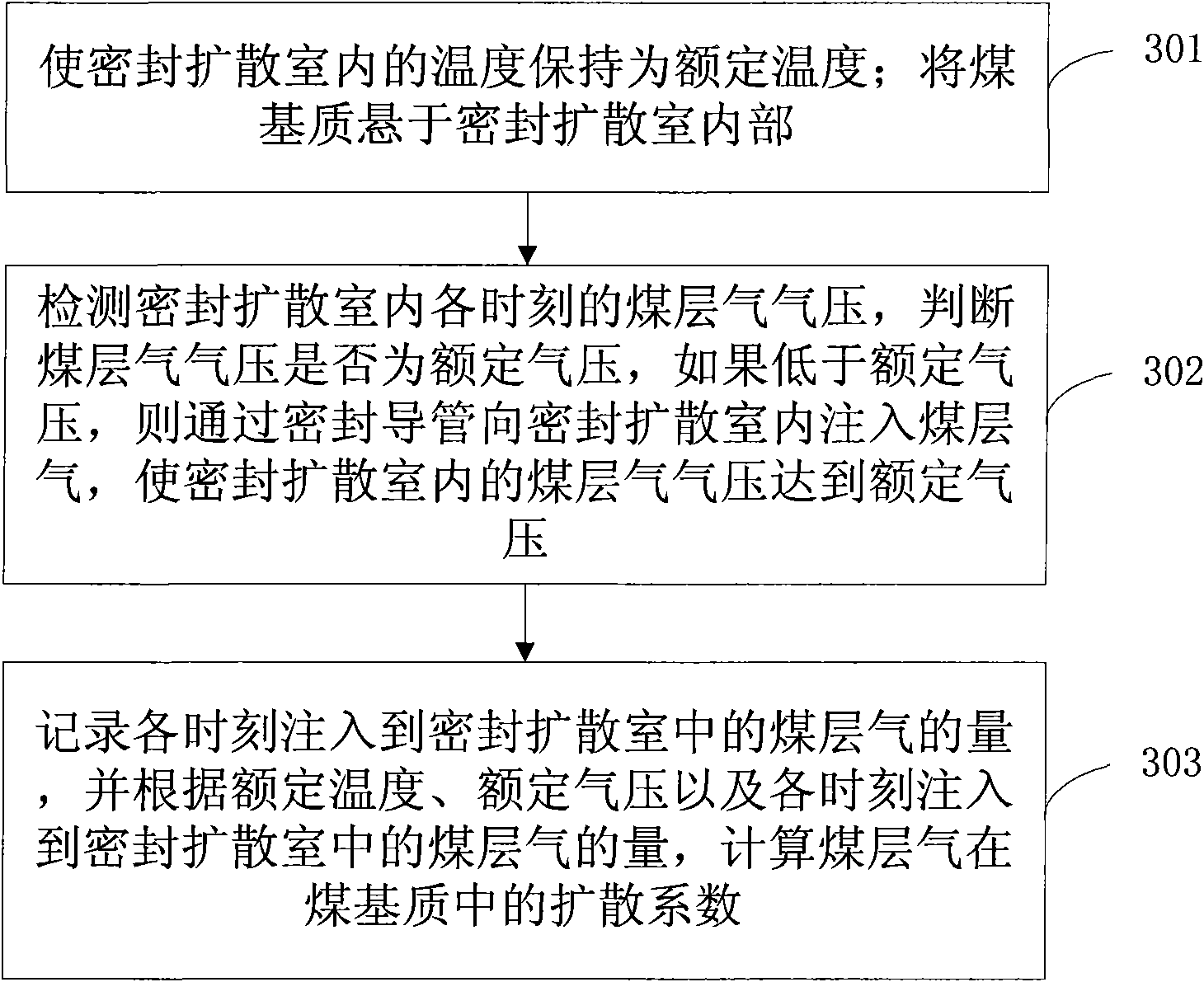

[0059] The core idea of the present invention is: use a constant temperature device to keep the temperature in the sealed diffusion chamber at the rated temperature, suspend the coal matrix inside the sealed diffusion chamber, so that all surfaces of the coal matrix can fully contact with the coalbed gas in the sealed diffusion chamber; Use a constant pressure device to detect the CBM pressure in the sealed diffusion chamber at each moment, and judge whether it maintains the rated pressure. If it is lower than the rated pressure, then inject the CBM into the sealed diffusion chamber through the sealed conduit, so that the CBM pressure in the sealed diffusion chamber reaches Rated air pressure; at the same time, record the amount of CBM injected into the sealed diffusion chamber at each time, and then calculate the CBM in the coal matrix according to the rated temperature, rated air pressure and the amount of CBM injected into the sealed diffusion chamber at each time Diffusio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com