Ball-throwing type high energy gas fracturing device

A technology of high-energy gas fracturing and high-energy gas, which is applied in the field of coalbed methane well fracturing, can solve the problems of limited production stimulation effect, difficulty in effective mining of coalbed methane, and low proportion of fractured fissures, so as to save time, reduce consumption intensity, The effect of increasing the permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

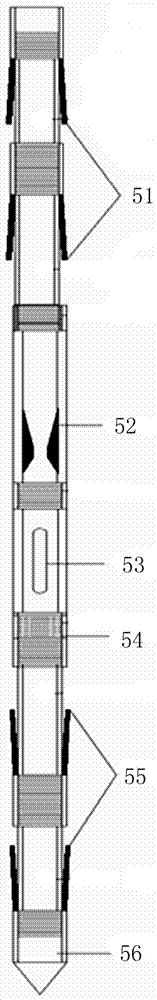

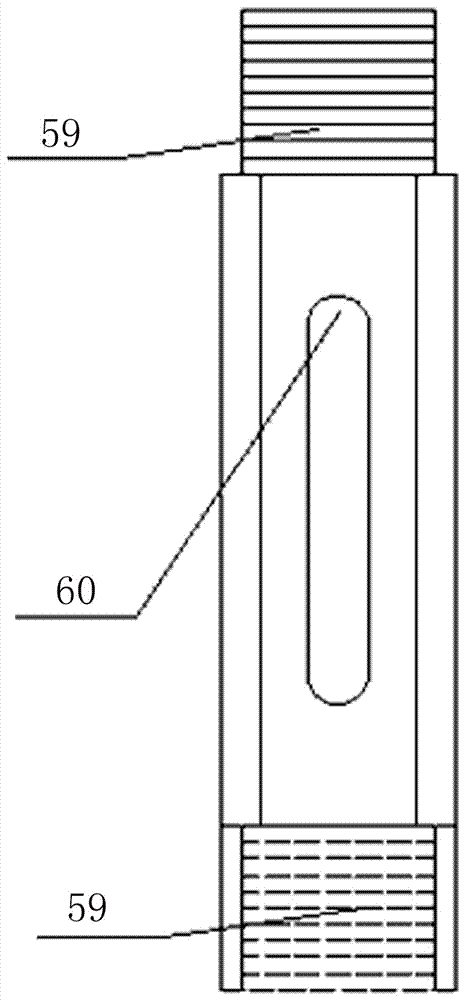

[0021] like figure 1 The pitching-type high-energy gas fracturing device shown includes an upper isolation unit 51, a shock trigger unit 52, an energy release unit 53, a pressure recording unit 54, a lower isolation unit 55, and guide shoes 56 connected in sequence from top to bottom. , the vibration trigger unit 52 completes the vibration of the ball sealing ball, the energy release unit 53 completes the release of the high-energy gas produced by the sealing ball burst, and the top of the upper isolation unit 51 is connected with the ground fracturing vehicle pump truck through the coiled tubing. The device can meet the two main contents of vibration and release, and the released gas can enter the target layer. The functions of each unit are as follows:

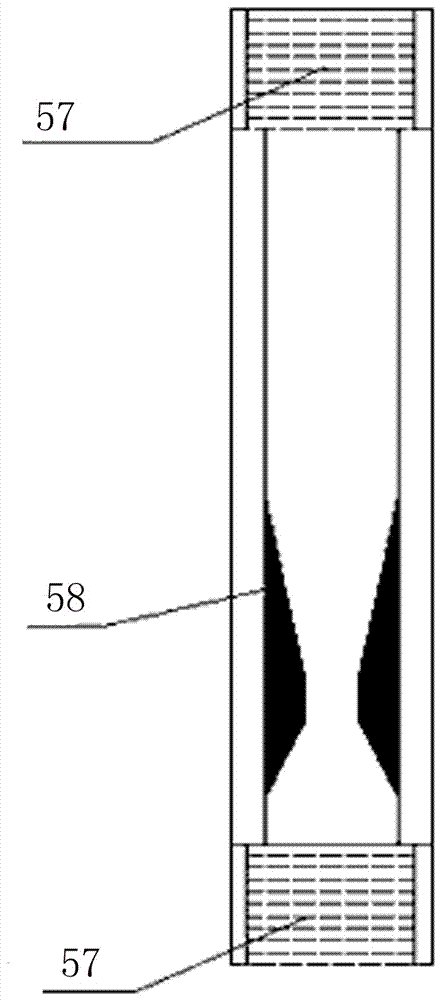

[0022] 1) Upper and lower cup packer units

[0023] The upper isolation unit 51 and the lower isolat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com