Pulverized coal stabilizer for coal bed gas reservoir and application method thereof

A stabilizer and coalbed methane technology, which is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of high requirements for use, stratum blockage, short validity period, etc., and achieve good water solubility , good weather resistance, simple on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A coal powder stabilizer used in coalbed methane reservoirs is prepared according to the following mass percentages: 40% of 2-chloroethyltrimethylammonium chloride, 5% of zirconium oxychloride, 25% of methanol and 30% of water.

[0034] Its preparation method is to directly mix all raw materials in proportion and evenly, and then it can be used directly.

[0035] Its method of use includes the following situations:

[0036] In the pre-fluid stage, the pulverized coal stabilizer is prepared and then pumped into the formation;

[0037] During the fracturing process, the pulverized coal stabilizer is prepared and then pumped into the formation;

[0038] After fracturing, the pulverized coal stabilizer is pumped into the formation as a displacement fluid;

[0039] In the production process, when the wellbore is blocked, the pulverized coal stabilizer is prepared and pumped into the formation.

[0040] The performance test of the pulverized coal stabilizer of the present ...

Embodiment 2

[0050] A coal powder stabilizer for coalbed methane reservoirs, configured according to the following mass percentage: the synthetic product of epichlorohydrin and dimethylamine (synthetic conditions are: epichlorohydrin: dimethylamine is 1:1.2) 35% , zirconium oxychloride 5%, methanol 25%, water 35%.

[0051] The performance test of the pulverized coal stabilizer of the present embodiment is as follows:

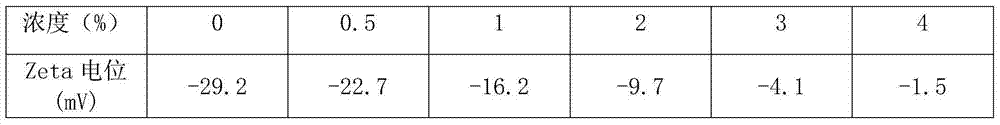

[0052] Zeta potential test

[0053] The product of embodiment 2 is added water and is made into the tensio-active agent dilute solution of different concentrations. After the coal sample was taken and pulverized, surfactants of different concentrations were added, stirred at high speed for 30 minutes, and allowed to stand for 24 hours to reach equilibrium, and the Zeta potential was measured. The experimental test temperature was room temperature. as shown in Table 3.

[0054] table 3

[0055] concentration(%) 0 0.25 0.5 0.75 1 2 4 Zeta potential -2...

Embodiment 3

[0062] A coal powder stabilizer for coalbed methane reservoirs is prepared according to the following mass percentages: 30% of octadecyltrimethylammonium bromide, 5% of zirconium hydroxy, 25% of methanol, and 40% of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com