Test method for coal matrix deformation mechanical parameters

A testing method and technology of mechanical parameters, applied in measuring devices, scientific instruments, suspension and porous material analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

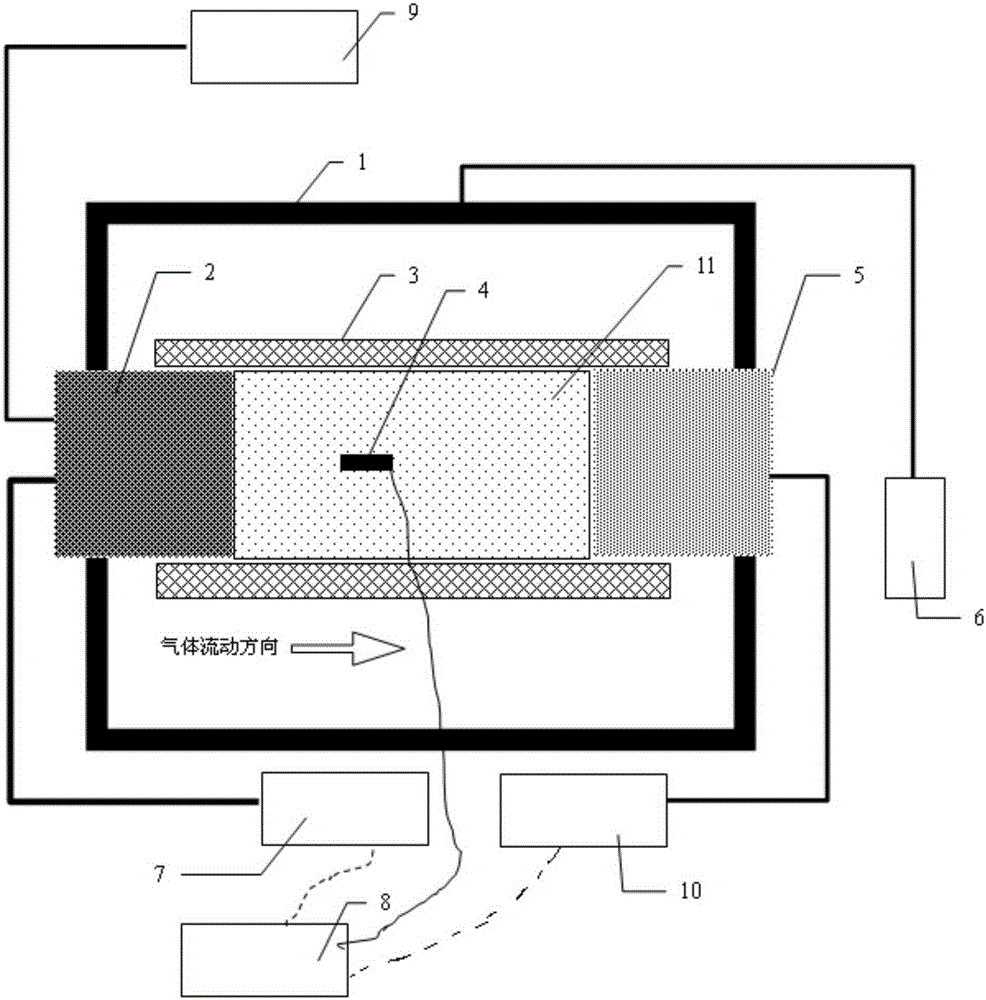

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. In this example, the Young's modulus of elasticity E in the direction perpendicular to the bedding direction is determined by uniaxial compression experiments. ⊥ =2.1GPa, Poisson's ratio ν perpendicular to the bedding direction ⊥ = 0.323.

[0041] like Figure 1-3 Shown, the coal matrix deformation mechanics parameter test method of the present invention, concrete test procedure is as follows:

[0042] The first step: processing and making coal sample test specimens

[0043] The whole coal block is processed into a cylindrical shape, the axial direction is perpendicular to the coal bedding direction, and the circumferential direction is parallel to the coal bedding direction; the axial strain gauge 4 is pasted on the outer surface of the cylindrical coal sample 11 along the axis; the coal sample 11 is inserted into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com