Patents

Literature

39results about "Chlorine production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

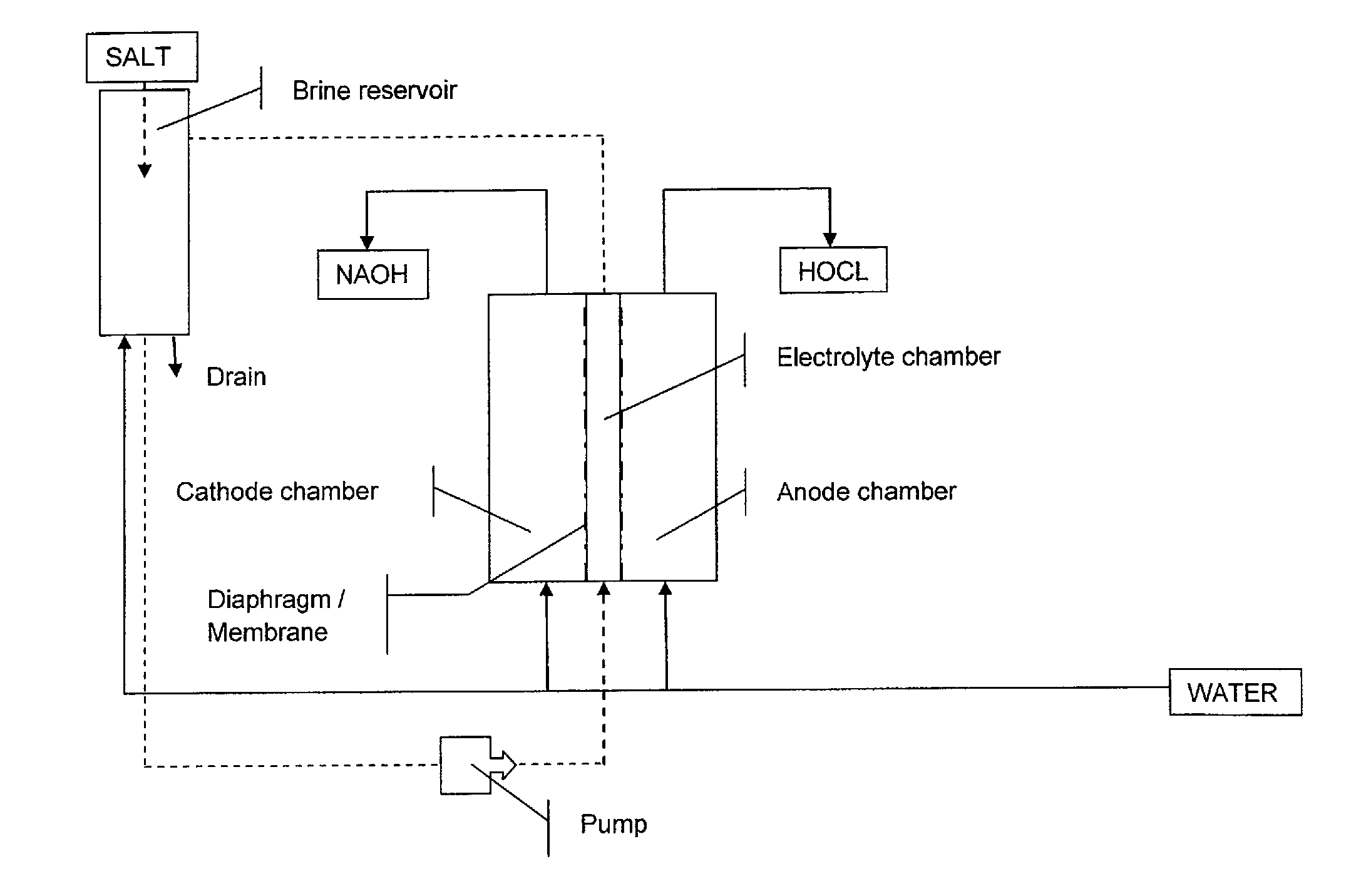

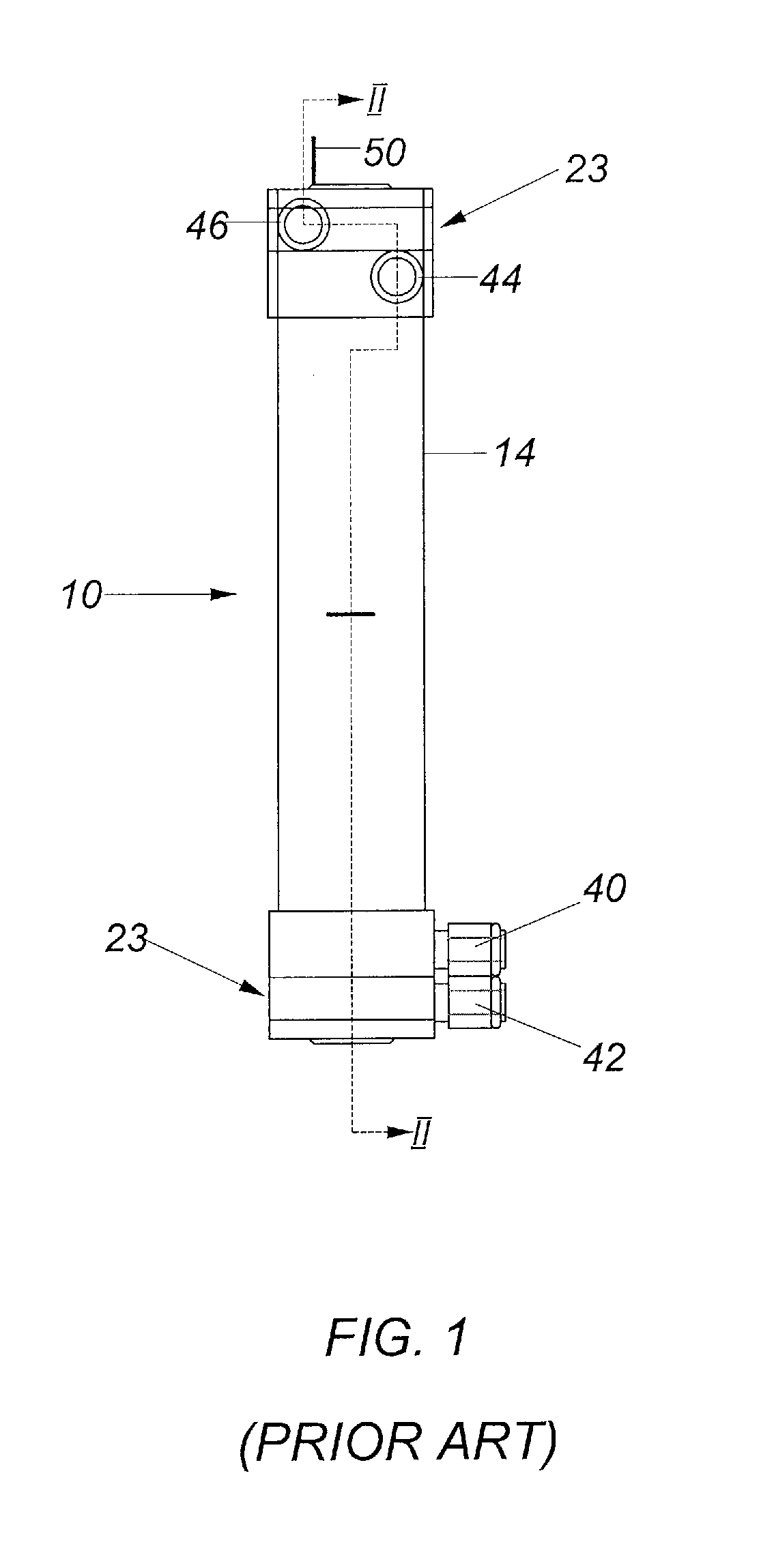

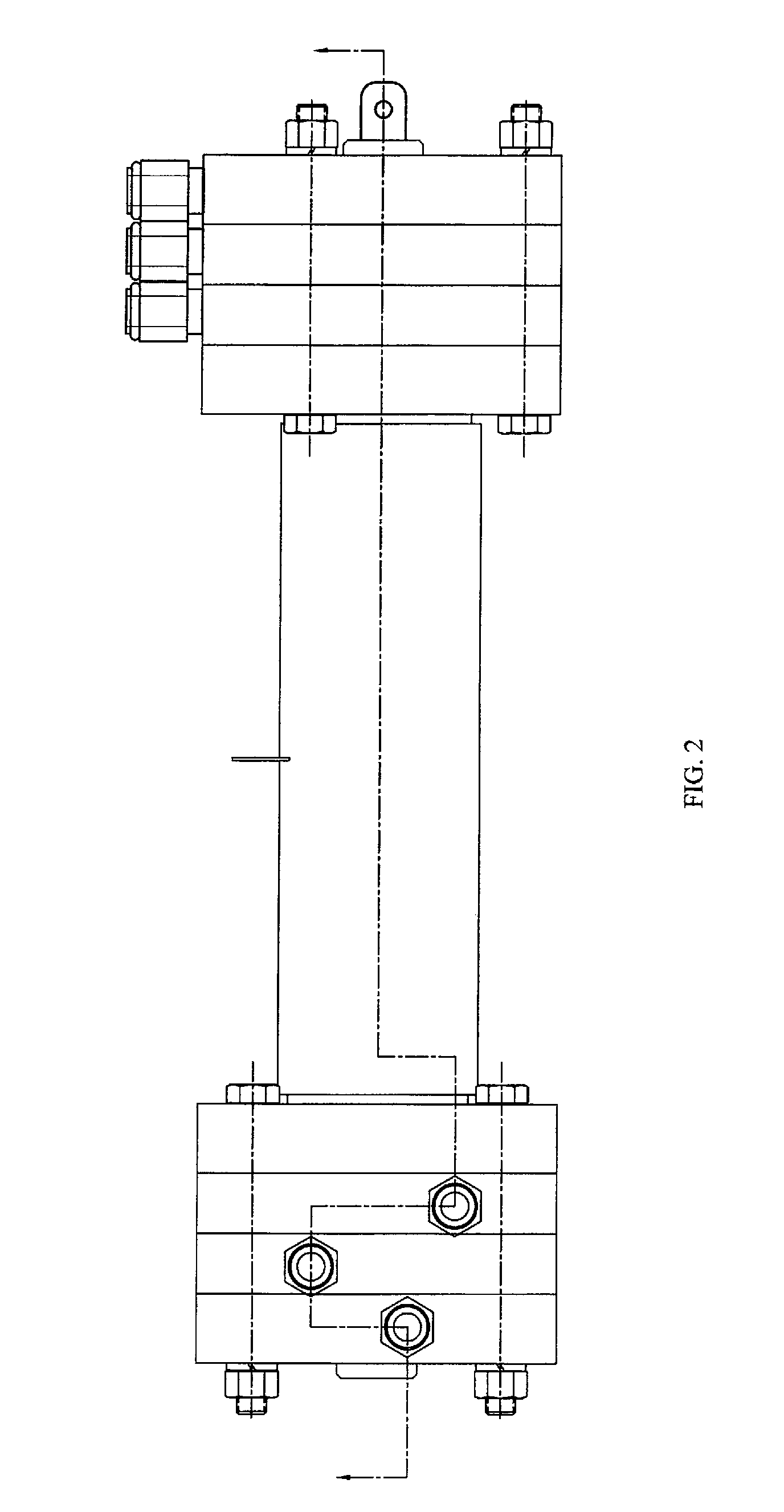

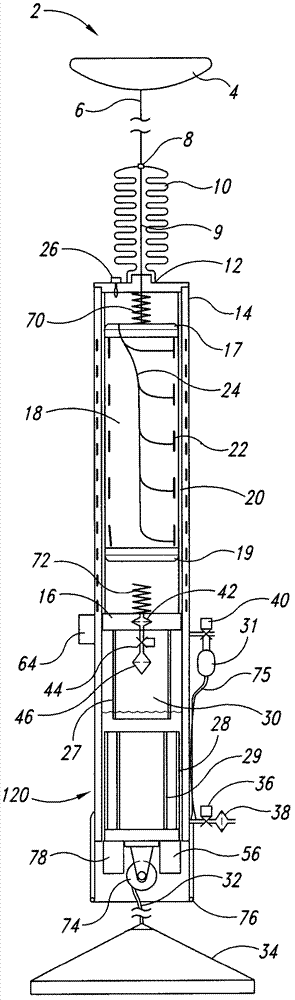

Dual diaphragm electrolysis cell assembly and method for generating a cleaning solution without any salt residues and simultaneously generating a sanitizing solution having a predetermined level of available free chlorine and pH

InactiveUS20130146473A1Improve cleanlinessSanitizing all hard surfacesCellsPhotography auxillary processesPotassiumCell assembly

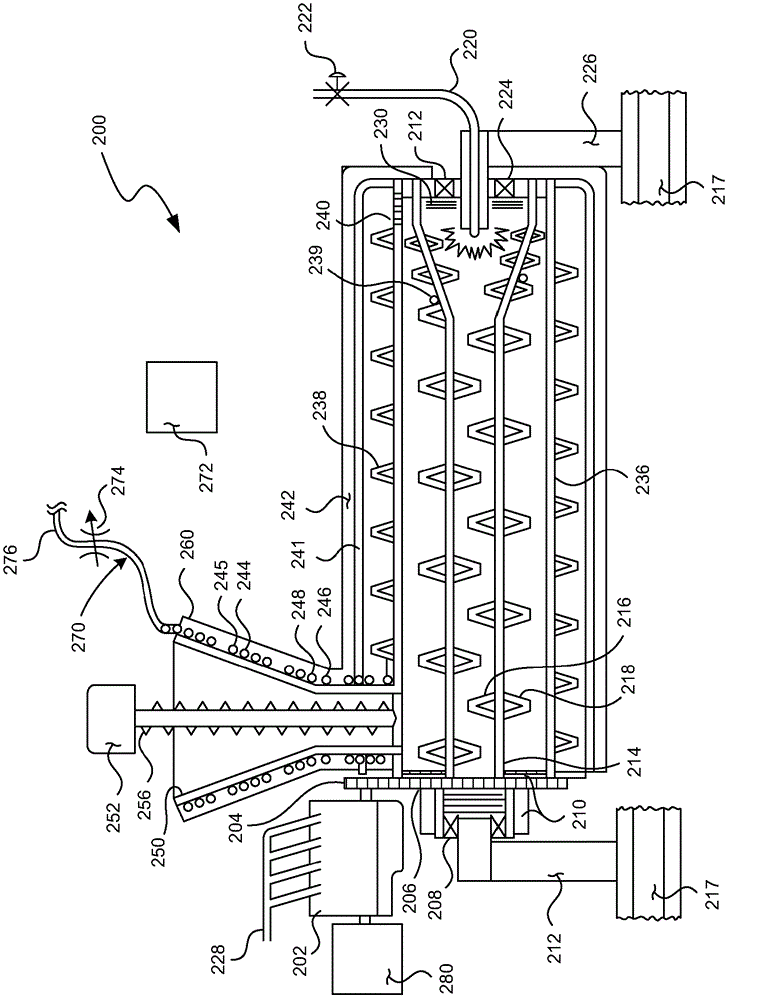

An Electrolysis cell assembly to produce diluted Sodium Hydroxide solutions (NAOH) and diluted Hypochlorous Acid (HOCL) solutions having cleaning and sanitizing properties. The electrolysis cell consists of two insulating end pieces for a cylindrical electrolysis cell comprising at least two cylindrical electrodes with two cylindrical diaphragms arranged co-axially between them. The method of producing different volumes and concentrations of diluted NAOH solutions and diluted HOCL solutions comprises recirculating an aqueous sodium chloride or potassium chloride solution into the middle chamber of the cylindrical electrolytic cell and feeding softened filtered water into the cathode chamber and into the anode chamber of the cylindrical electrolysis cell.

Owner:AQUAOX

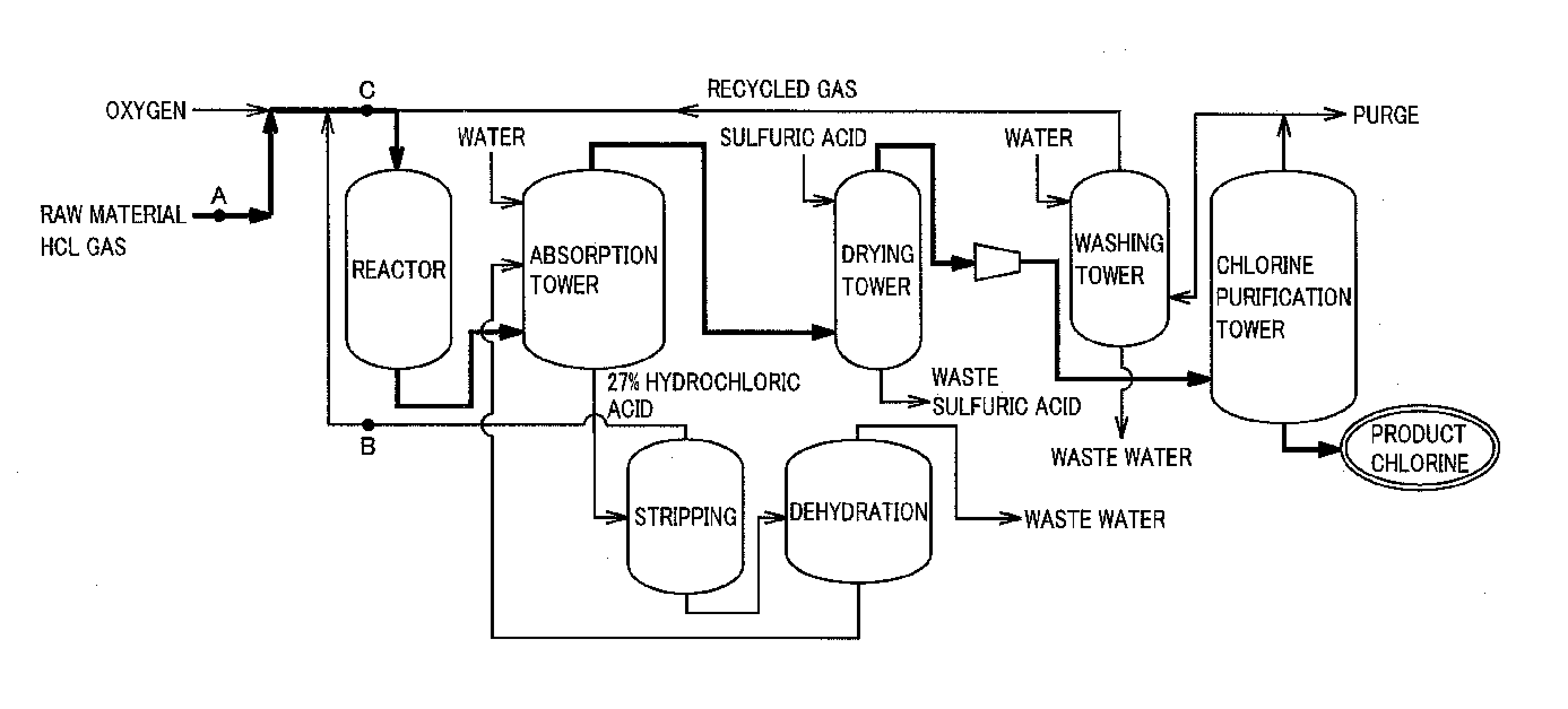

Method for producing chlorine

InactiveUS6977066B1High activityEquipment and operational costPreparation from chloridesChlorine productionReaction zoneOxygen

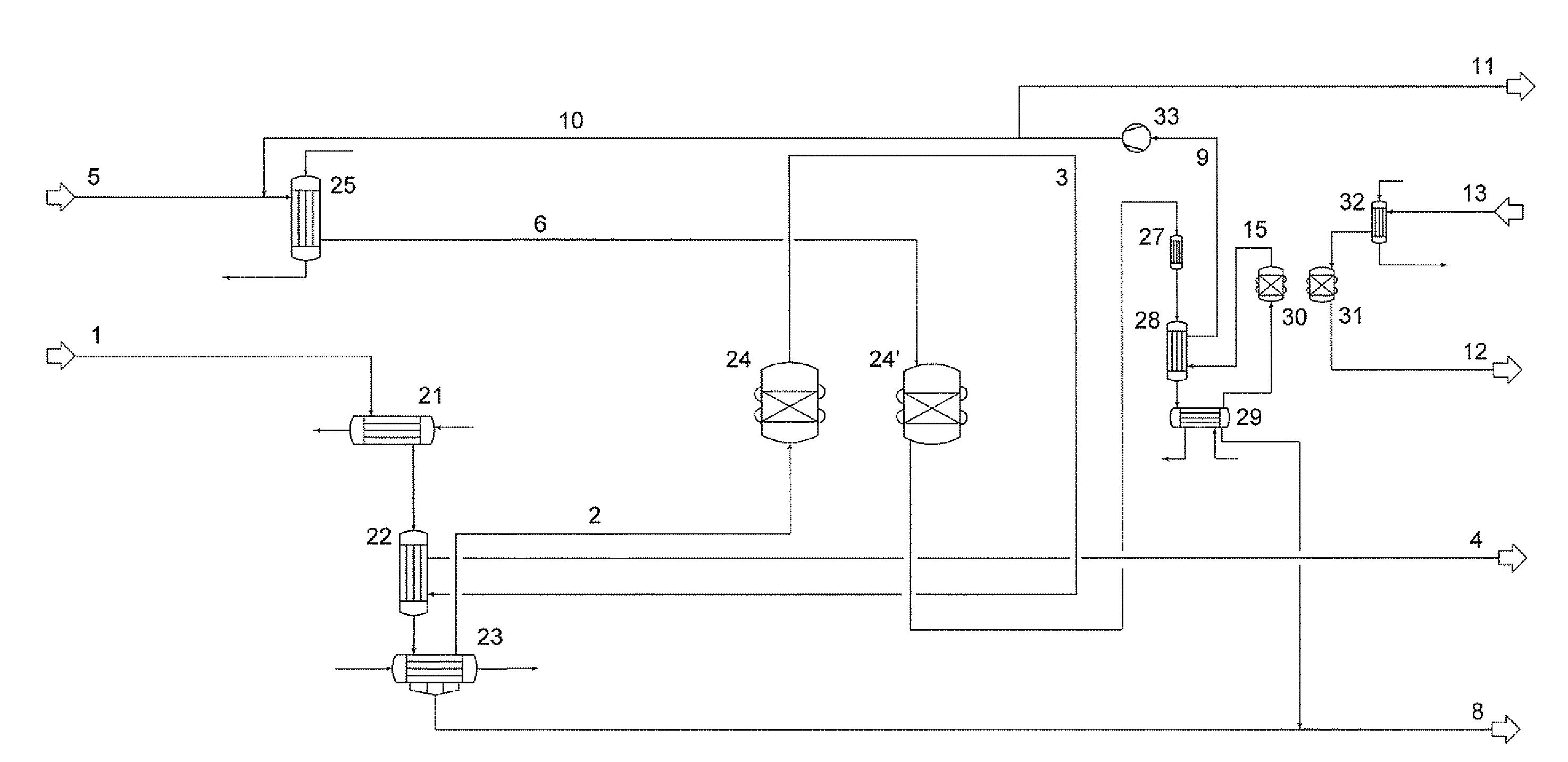

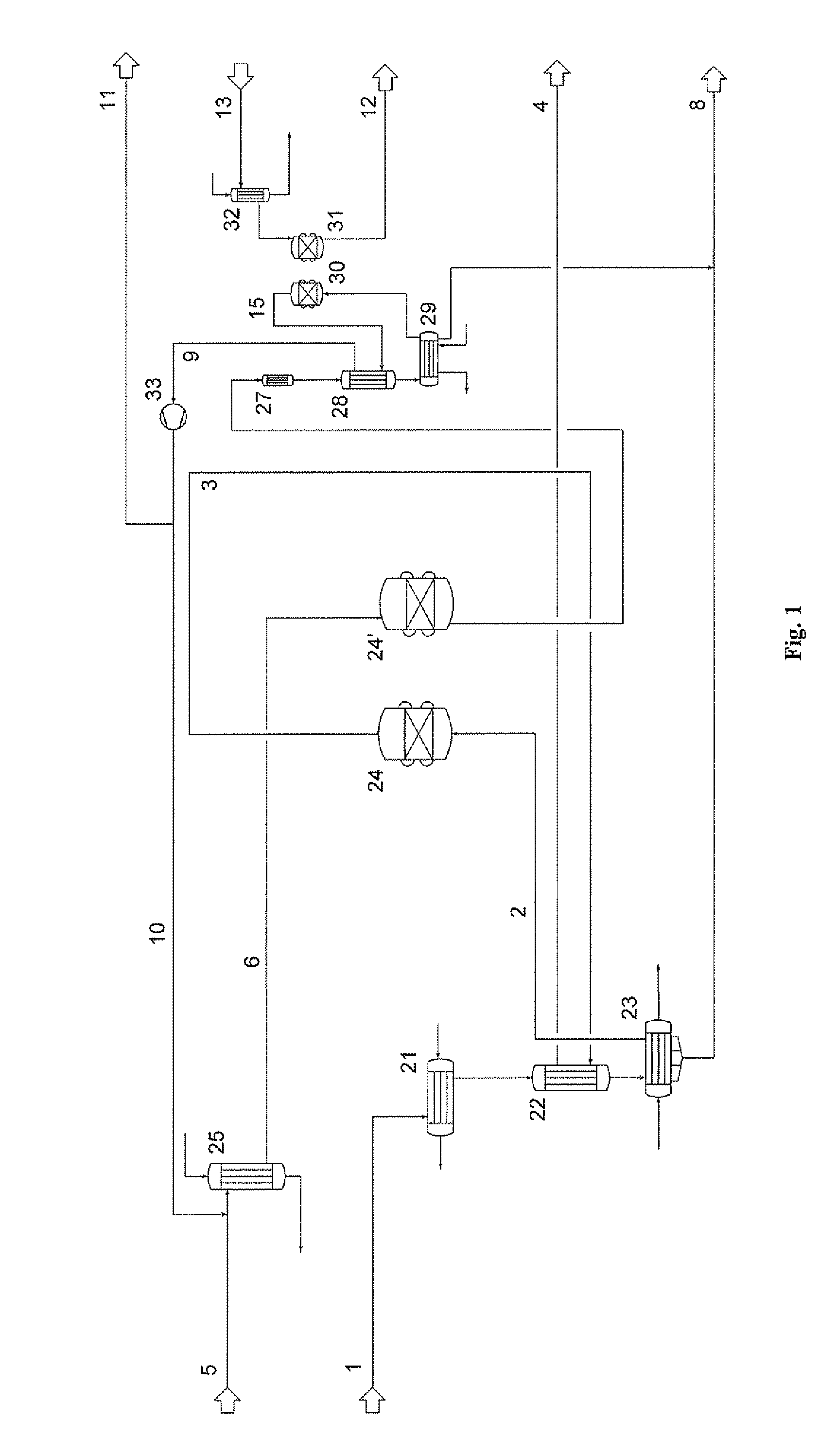

A process for producing chlorine comprising the step of oxidizing hydrogen chloride in a gas containing hydrogen chloride with a gas containing oxygen in the presence of a catalyst, wherein the oxidation of hydrogen chloride is carried out in at least two reaction zones each comprising a catalyst-packed layer, which are arranged in series, and a temperature in at least one of said reaction zones is controlled with a heat exchange system. According to this process, the stable activity of the catalyst is maintained and chlorine can be stably obtained at a high yield since the excessive hot spot in the catalyst-packed layer is suppressed and the catalyst-packed layer can be effectively used.

Owner:SUMITOMO CHEM CO LTD

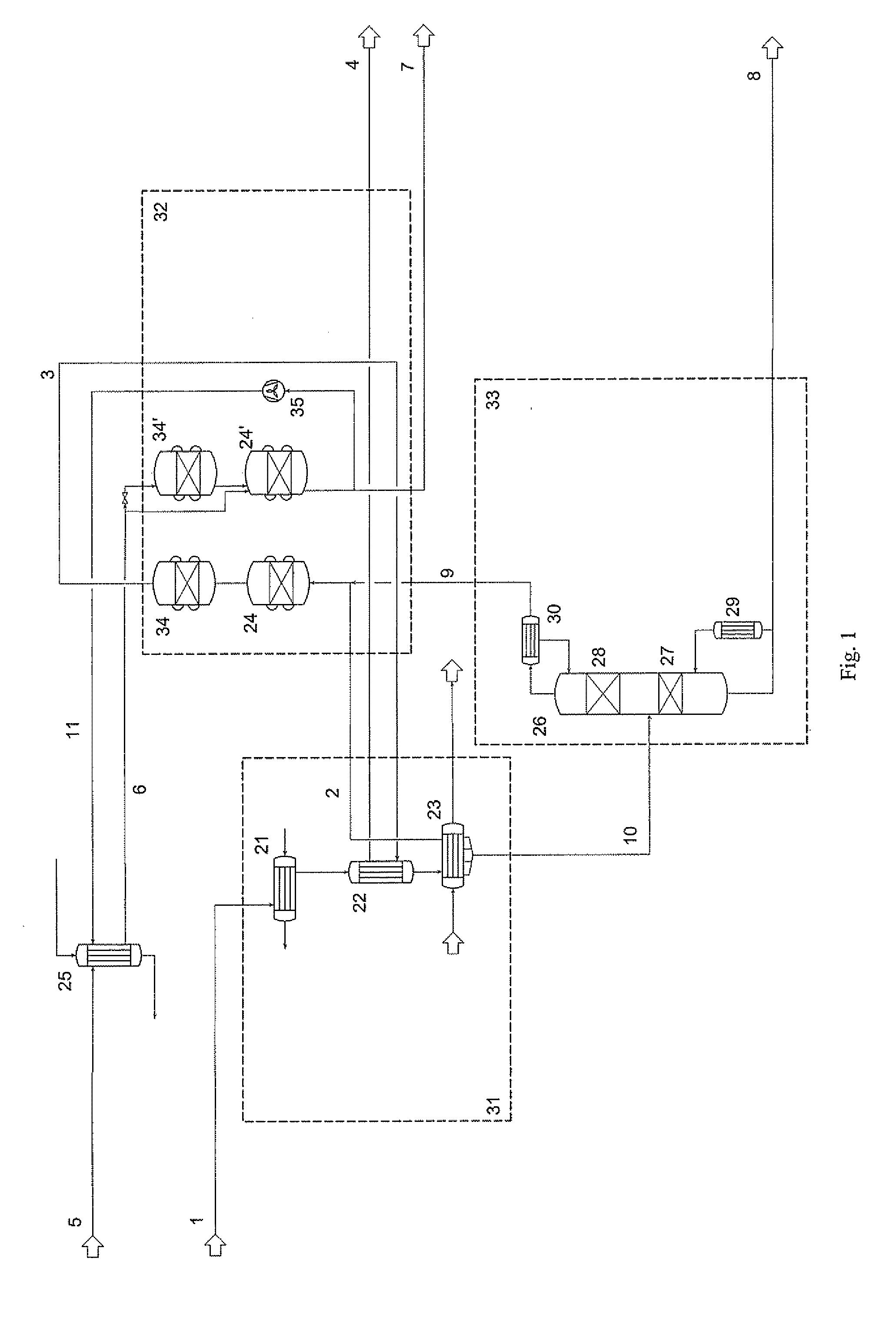

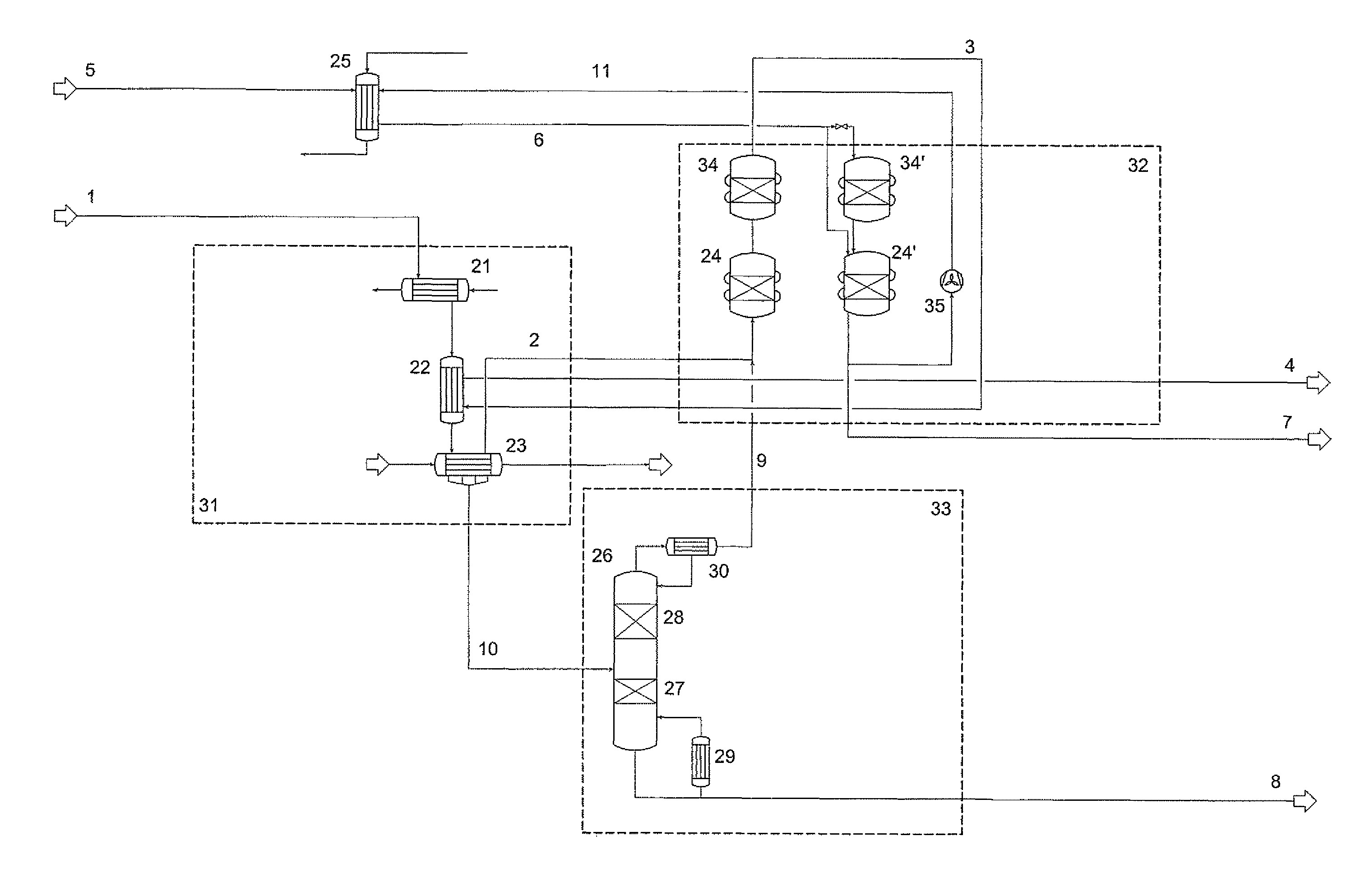

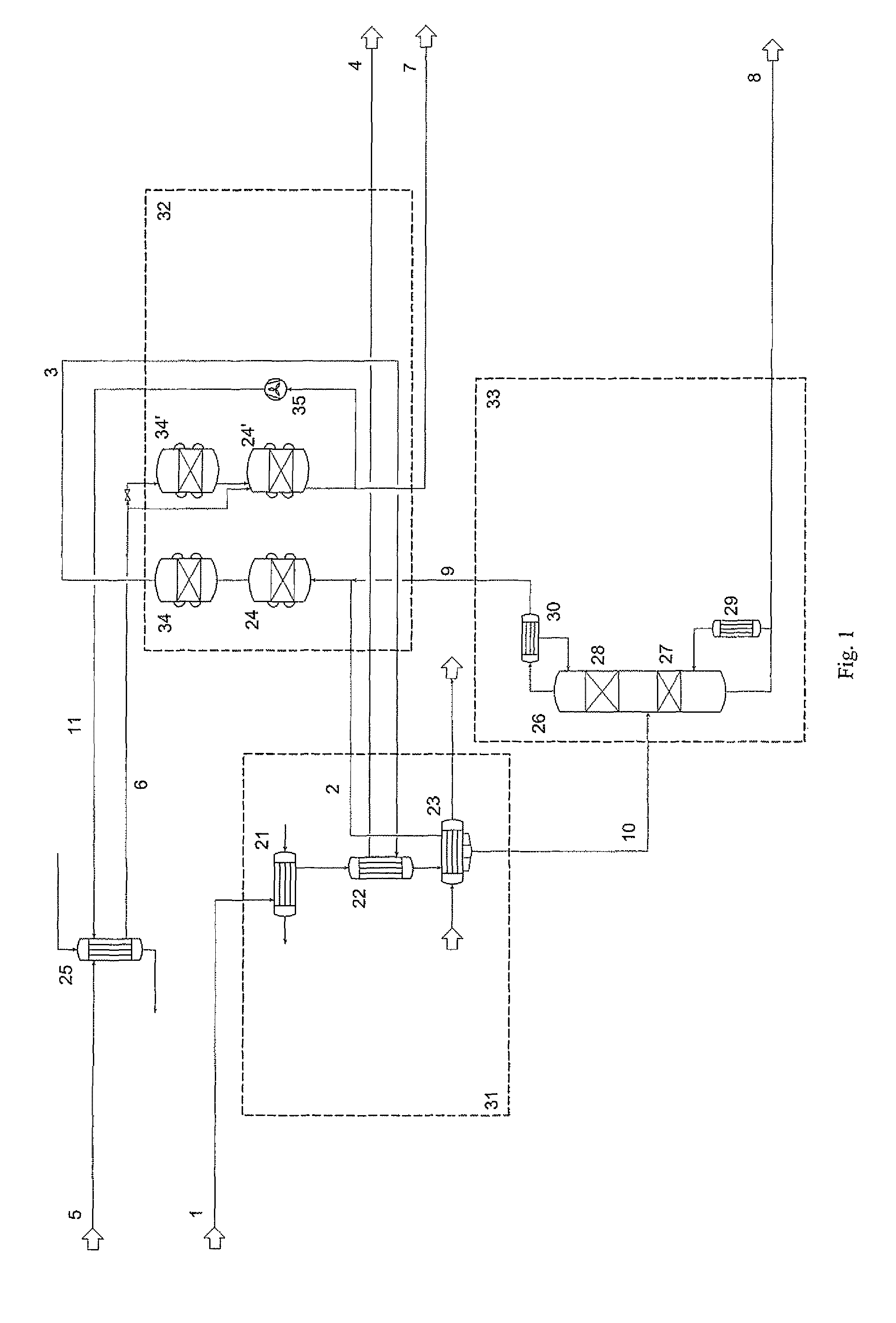

Processes for the production of chlorine from hydrogen chloride and oxygen

ActiveUS20080029404A1Overcome disadvantagesElectrolysis componentsPreparation from chloridesNitrogen gasOxygen

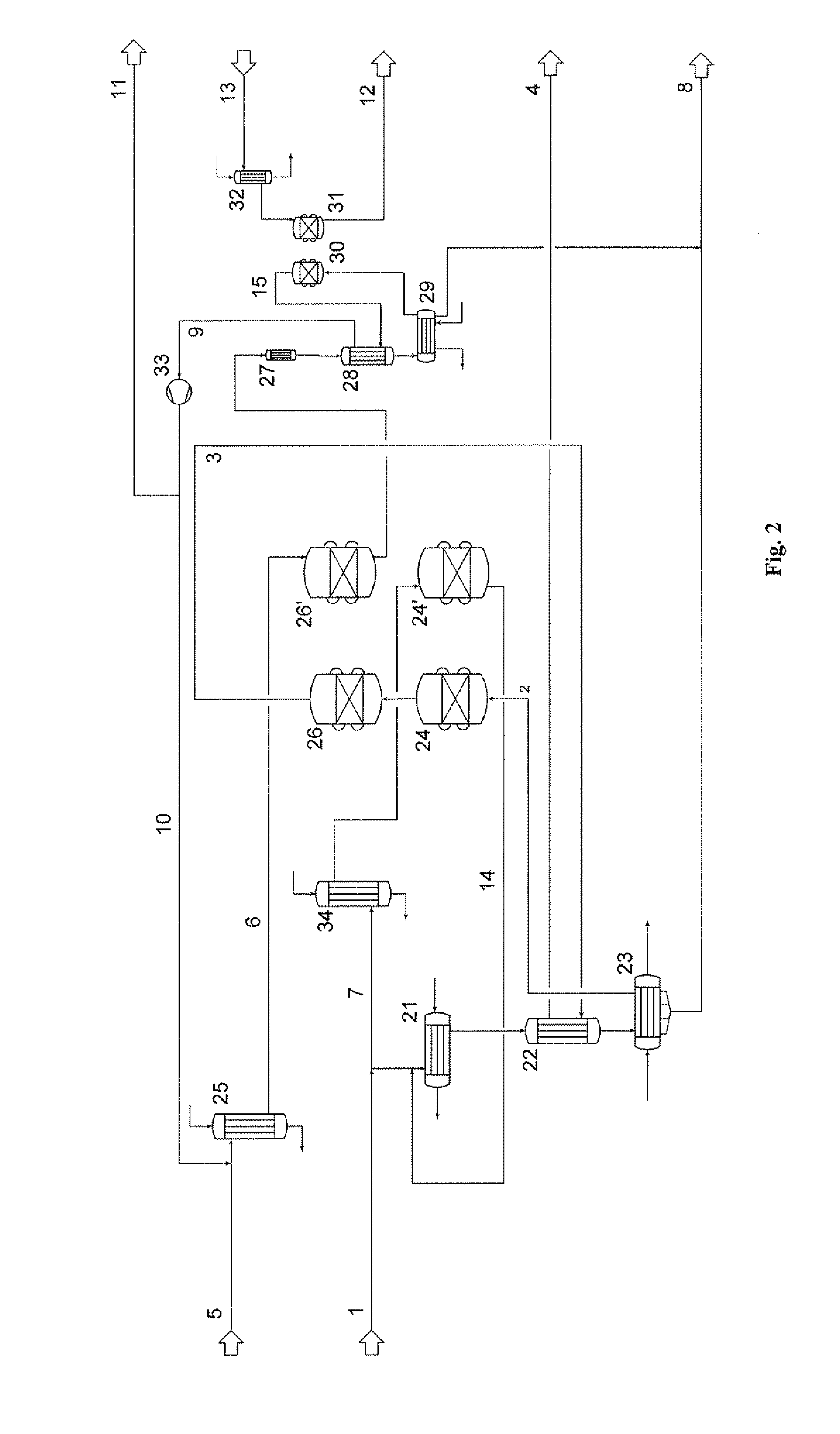

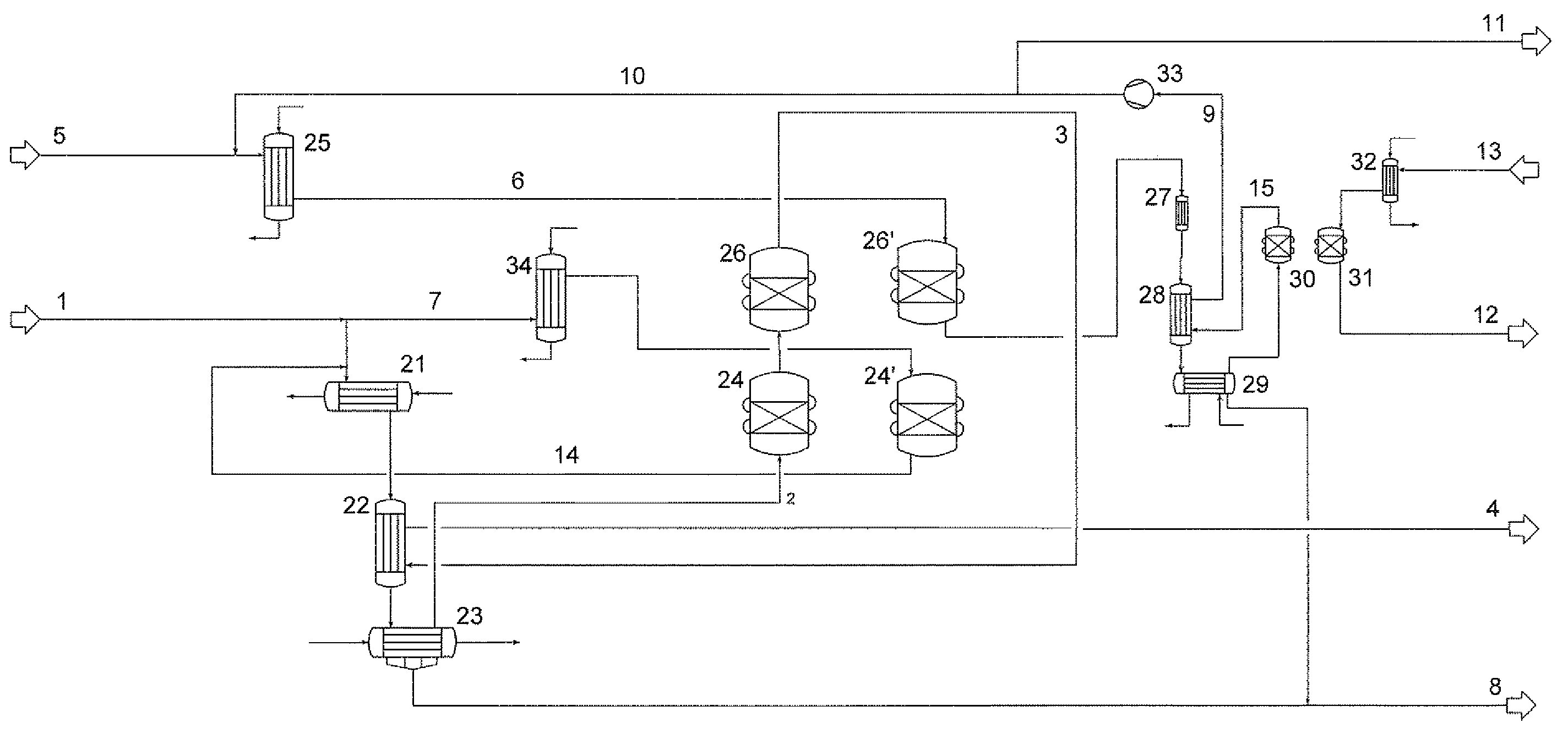

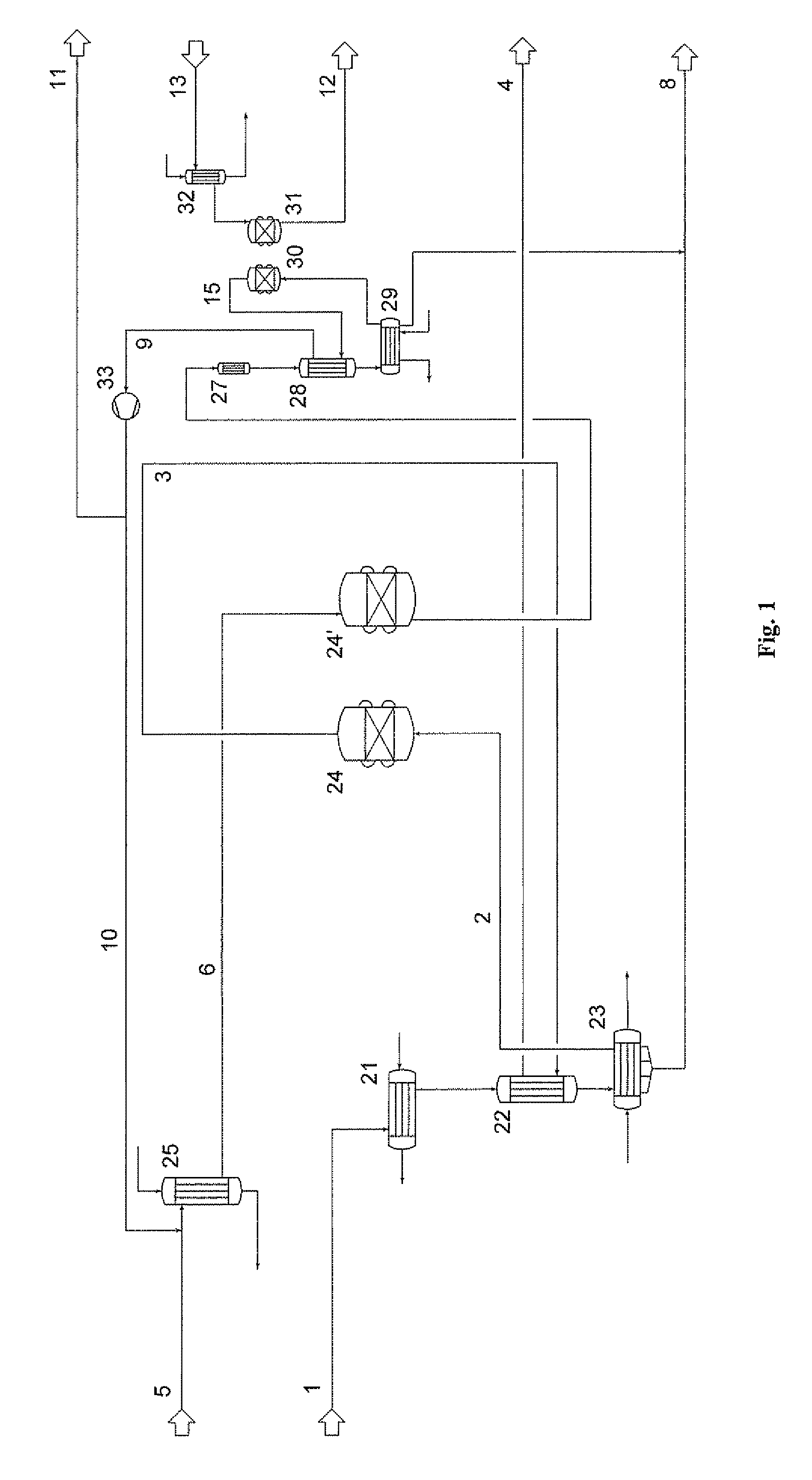

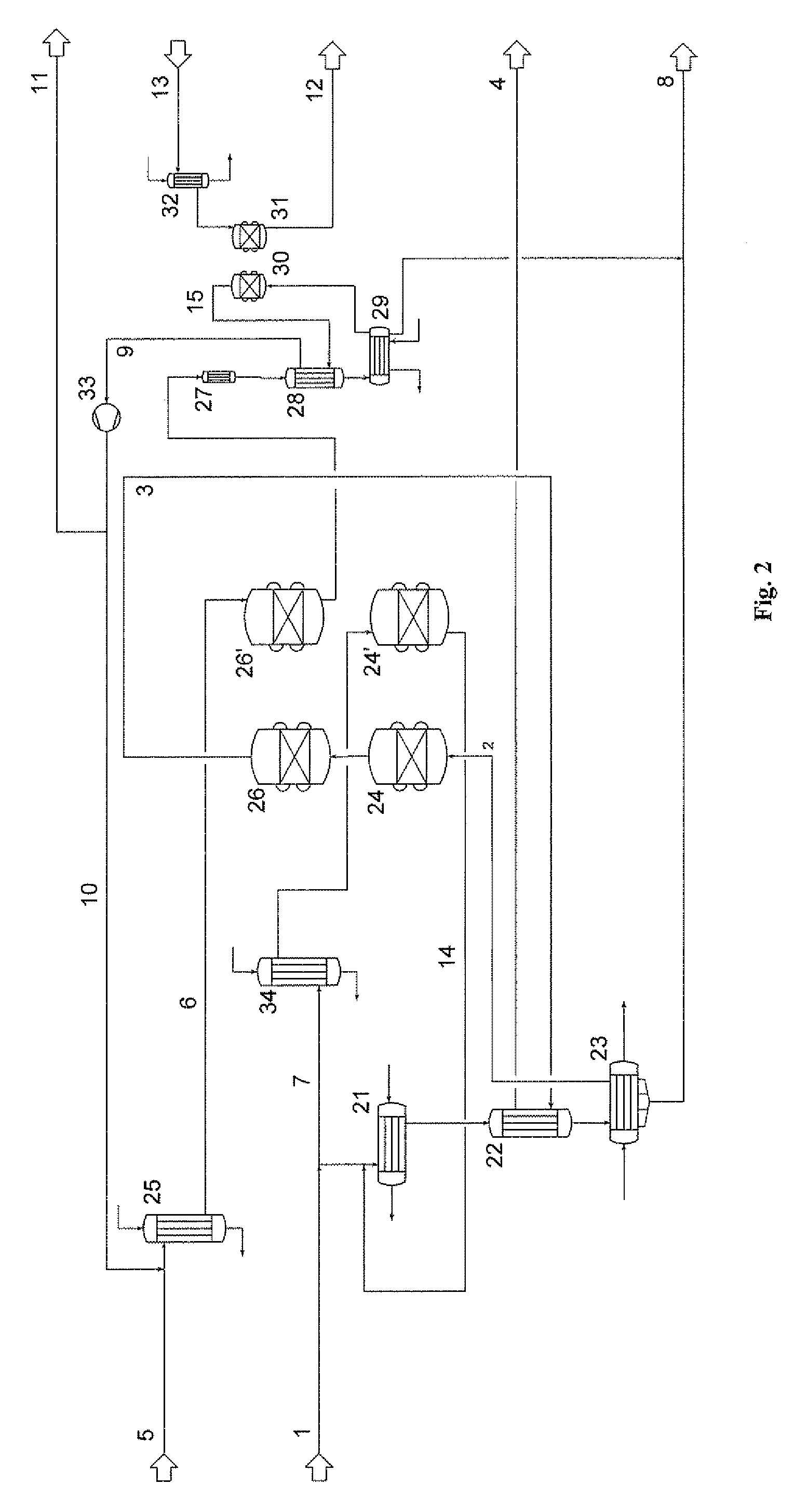

Processes for the production of chlorine by multi-stage oxidation, for example, by thermal reaction of hydrogen chloride with oxygen using catalysts or by non-thermal activated reaction of hydrogen chloride with oxygen, in which the gas mixture formed in the reaction, comprising the target products chlorine and water, unreacted hydrogen chloride and oxygen, and possibly other secondary constituents, such as carbon dioxide and nitrogen, (a) is cooled to condense hydrochloric acid as an aqueous solution of hydrogen chloride and (b) the aqueous solution of hydrogen chloride formed is separated from the gas mixture, characterised in that (c) the separated aqueous solution of hydrogen chloride is fed at least partially to an electrochemical oxidation in which at least part of the hydrogen chloride is oxidised to chlorine, (d) the chlorine gas occurring in step d) is optionally added to the gas mixture occurring in step c), (e) the residues of water present in the gas mixture from steps c) and e), in particular by washing with sulfuric acid, are removed, (f) the chlorine-rich gas mixture forming is freed of oxygen and optionally of secondary constituents.

Owner:COVESTRO DEUTSCHLAND AG

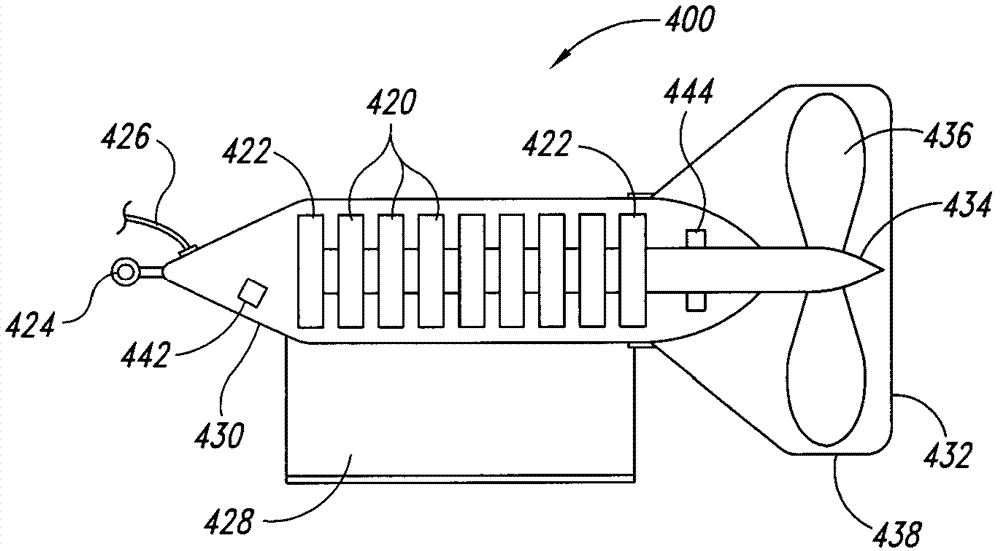

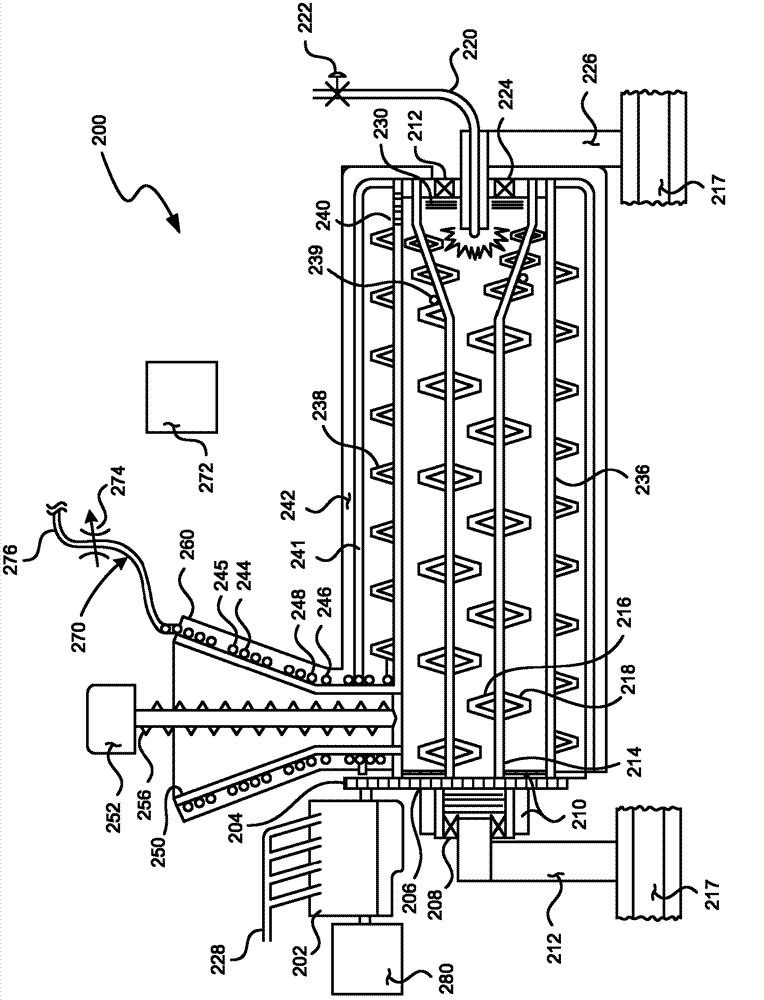

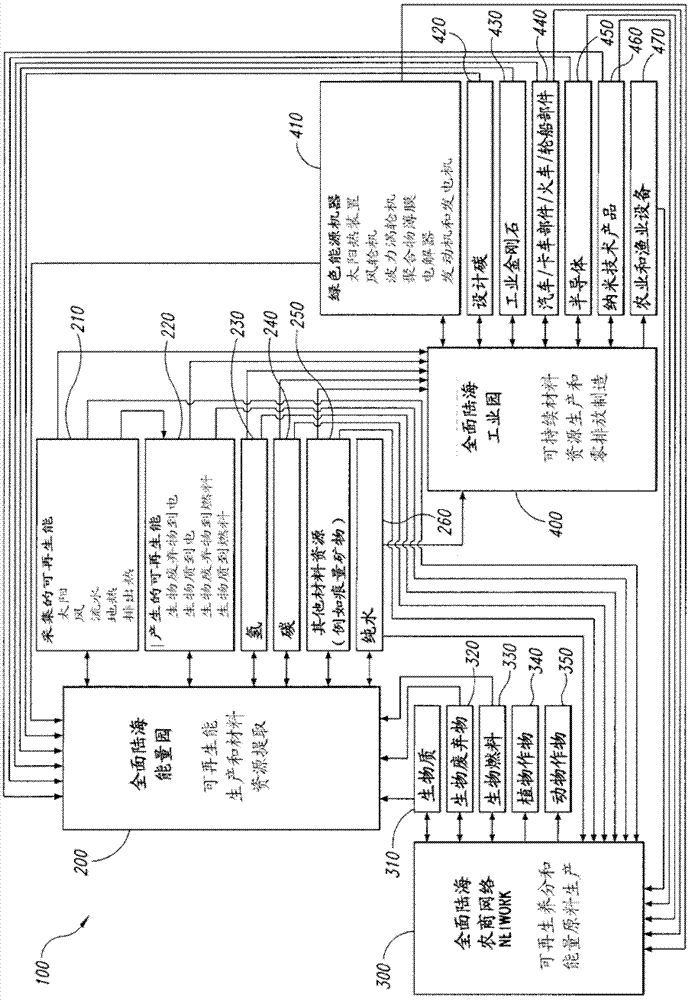

Energy conversion assemblies and associated methods of use and manufacture

InactiveCN102713154ASolar heating energyInternal combustion piston enginesChemical treatmentHigh rate

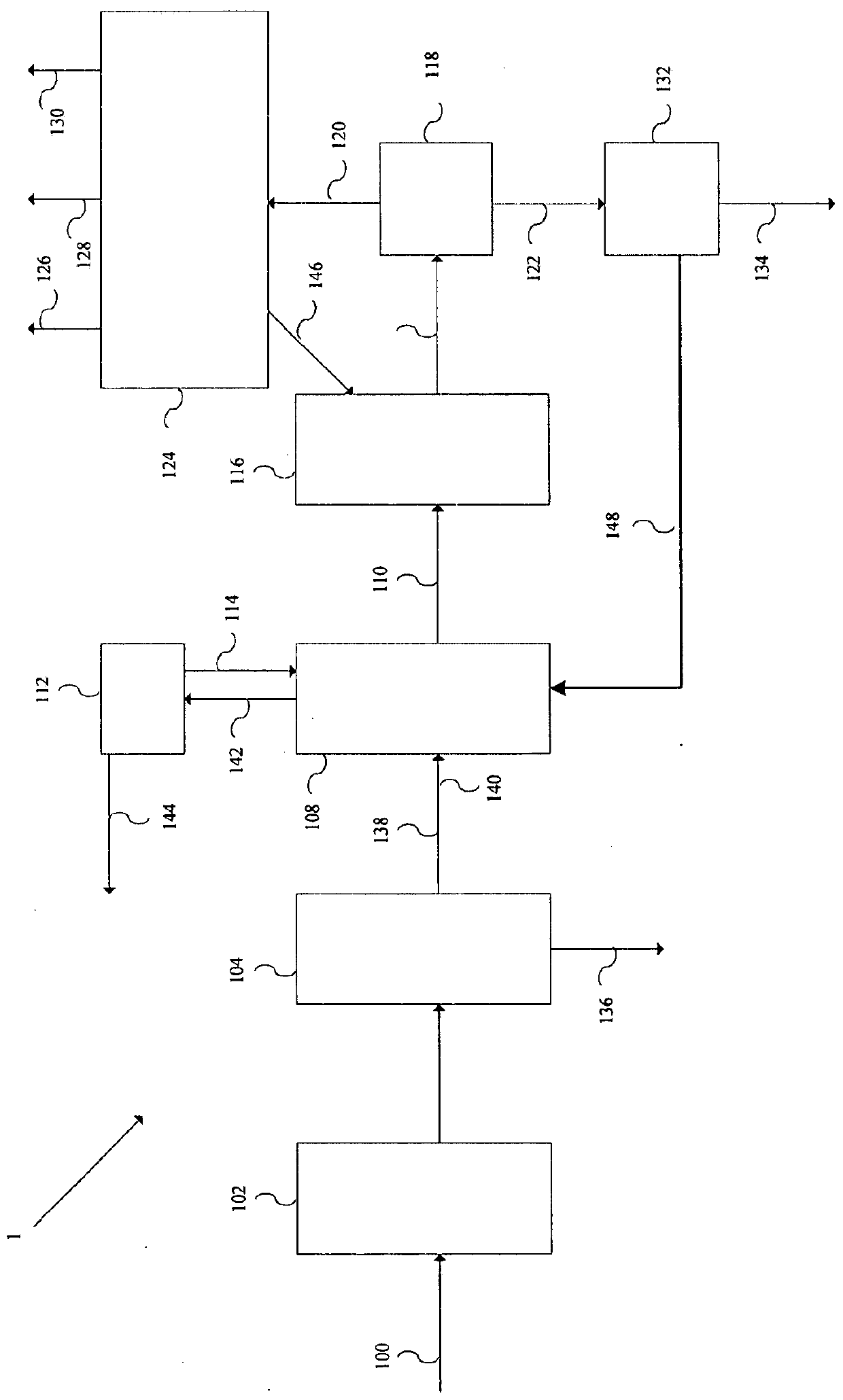

Embodiments of the disclosure are directed to conversion of renewable energy such as solar, wind, falling water, wave and biomass resources into energy forms for practical transport by existing electricity and natural gas transport systems and includes embodiments for cyclic conversion of rectilinear forces into electricity wherein charged particles force a separate population of charged particles to flow in a separate circuit to create an electric current. Forces exerted at a first frequency are converted into cyclic electrical current at a frequency that is a multiple of the frequency of the forces. Similar arrangements are provided for conversion of rotary forces into electricity. Components of the disclosure can be manufactured at a high rate from very low cost materials with minimum energy requirements for the purpose of generation of low-cost electricity from linear motion engines and renewable forces such as ocean waves and flowing fluids such as water or air. Corrosion and biofouling are eliminated by application of cathodic and chemical treatments produced by the operation of the disclosure. Various embodiments of the disclosure allow improved cogeneration and motor vehicles, household appliances, and industrial equipment to be operated on energy converted from rectilinear forces.

Owner:MCALISTER TECH LLC

Processes for removing organic components from gases containing hydrogen chloride

ActiveUS20080264253A1Reduce lossesSolidificationChlorine/hydrogen-chloride purificationHydrogen chlorideImpurity

Processes comprising: providing a crude gas stream having a temperature not exceeding 40° C., the crude gas stream comprising hydrogen chloride and at least one organic impurity; condensing at least a portion of the at least one organic impurity from the crude gas stream at a temperature not exceeding 0° C. to form a prepurified gas stream and a condensate comprising condensed organic impurity; subjecting at least a portion of the prepurified gas stream to adsorption on an adsorption medium to provide a purified gas stream; and separating the condensate into at least a head gas stream comprising residual hydrogen chloride and a sump stream comprising at least a portion of the condensed organic impurity.

Owner:COVESTRO DEUTSCHLAND AG

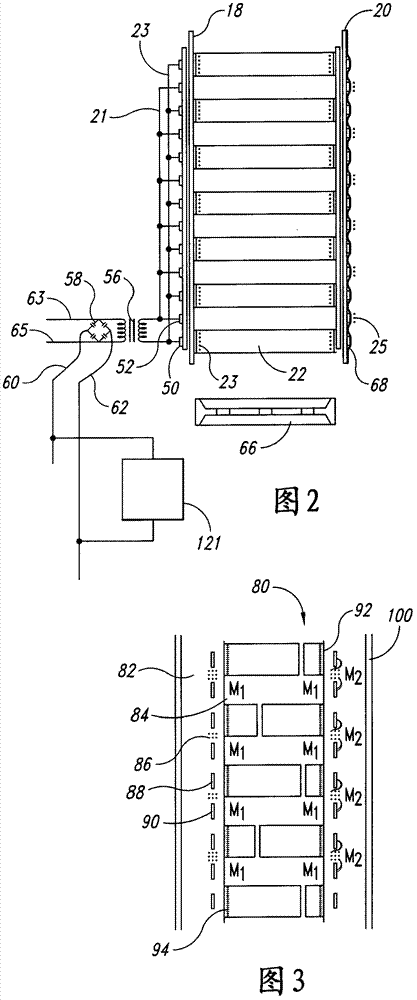

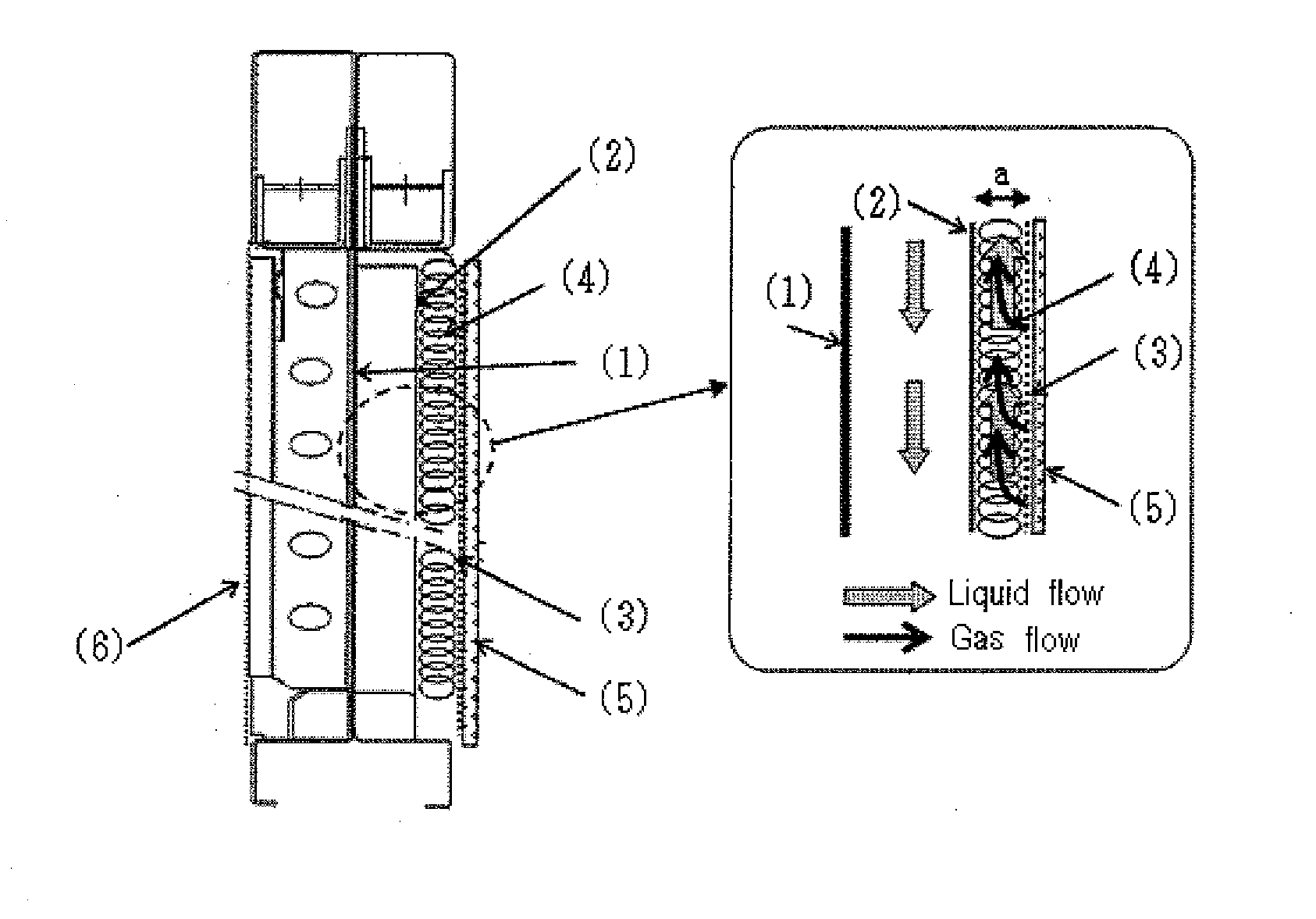

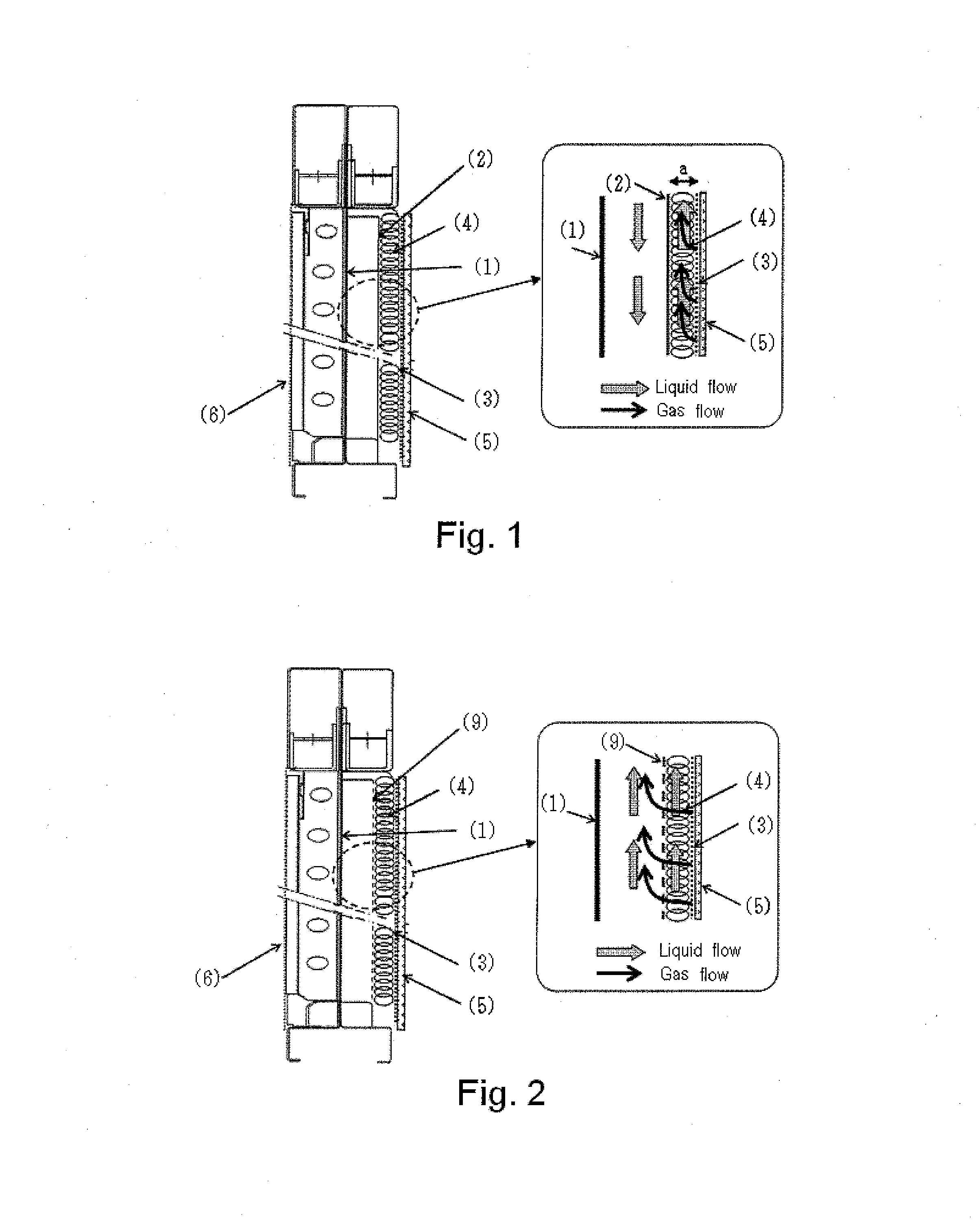

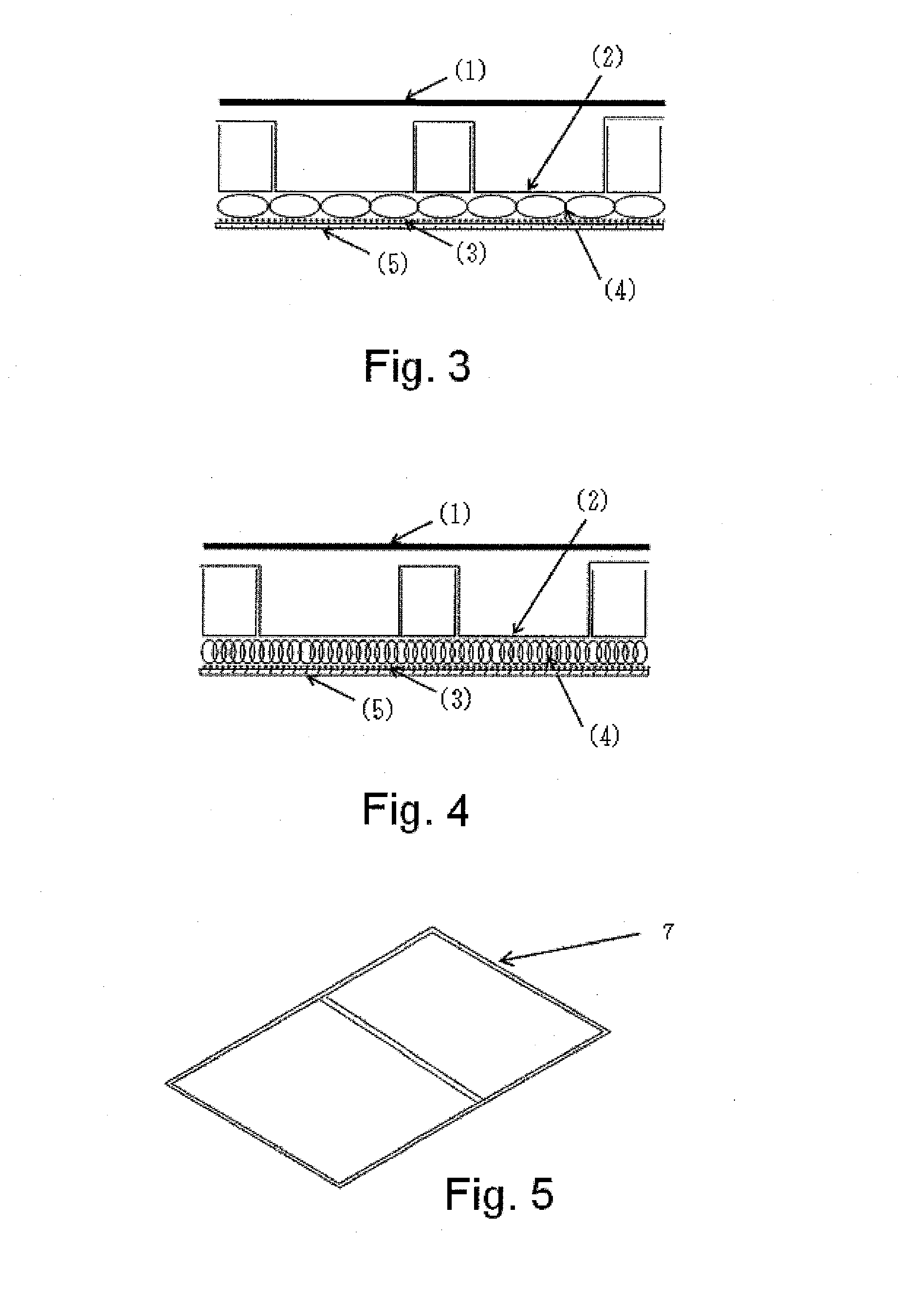

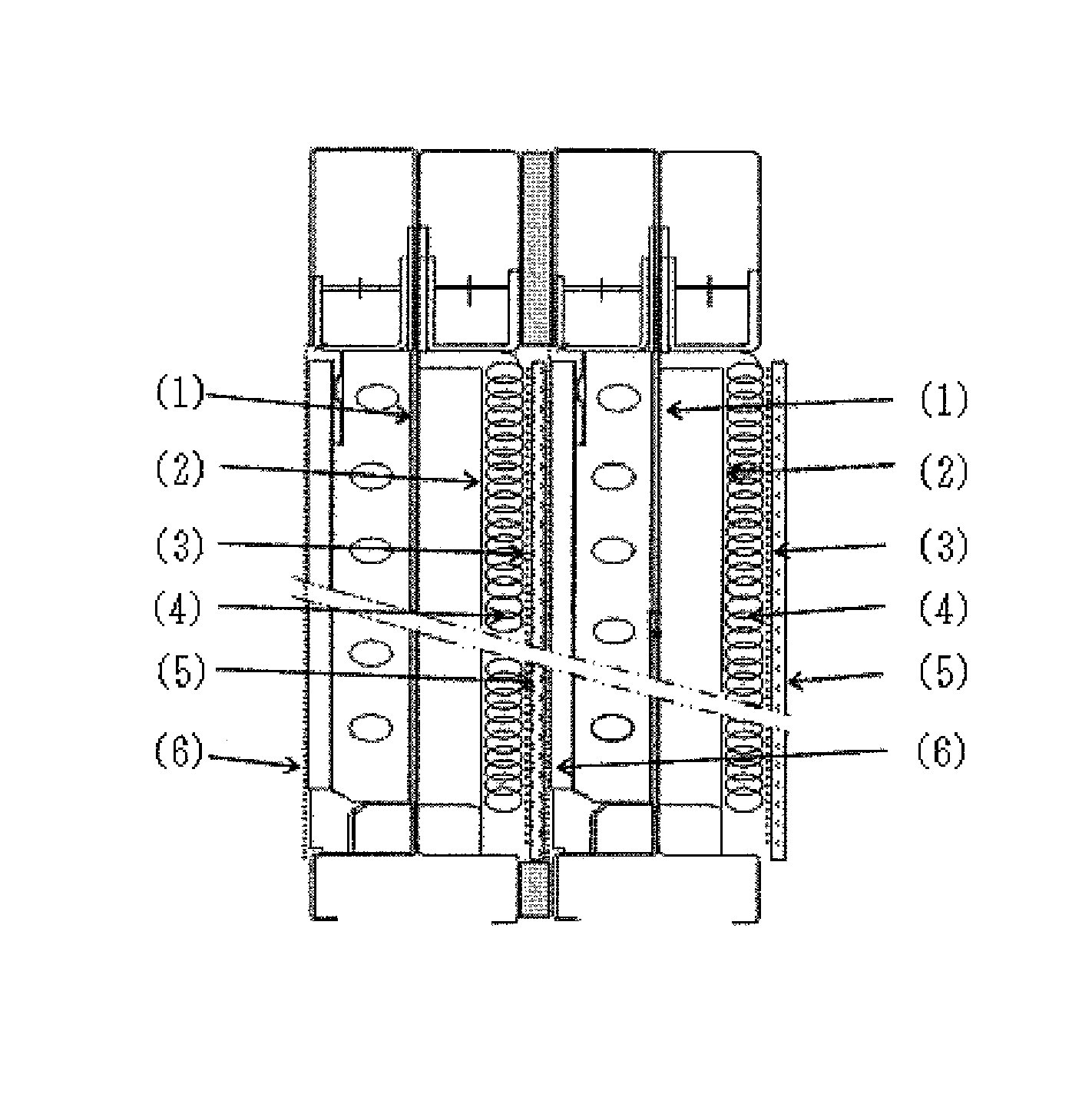

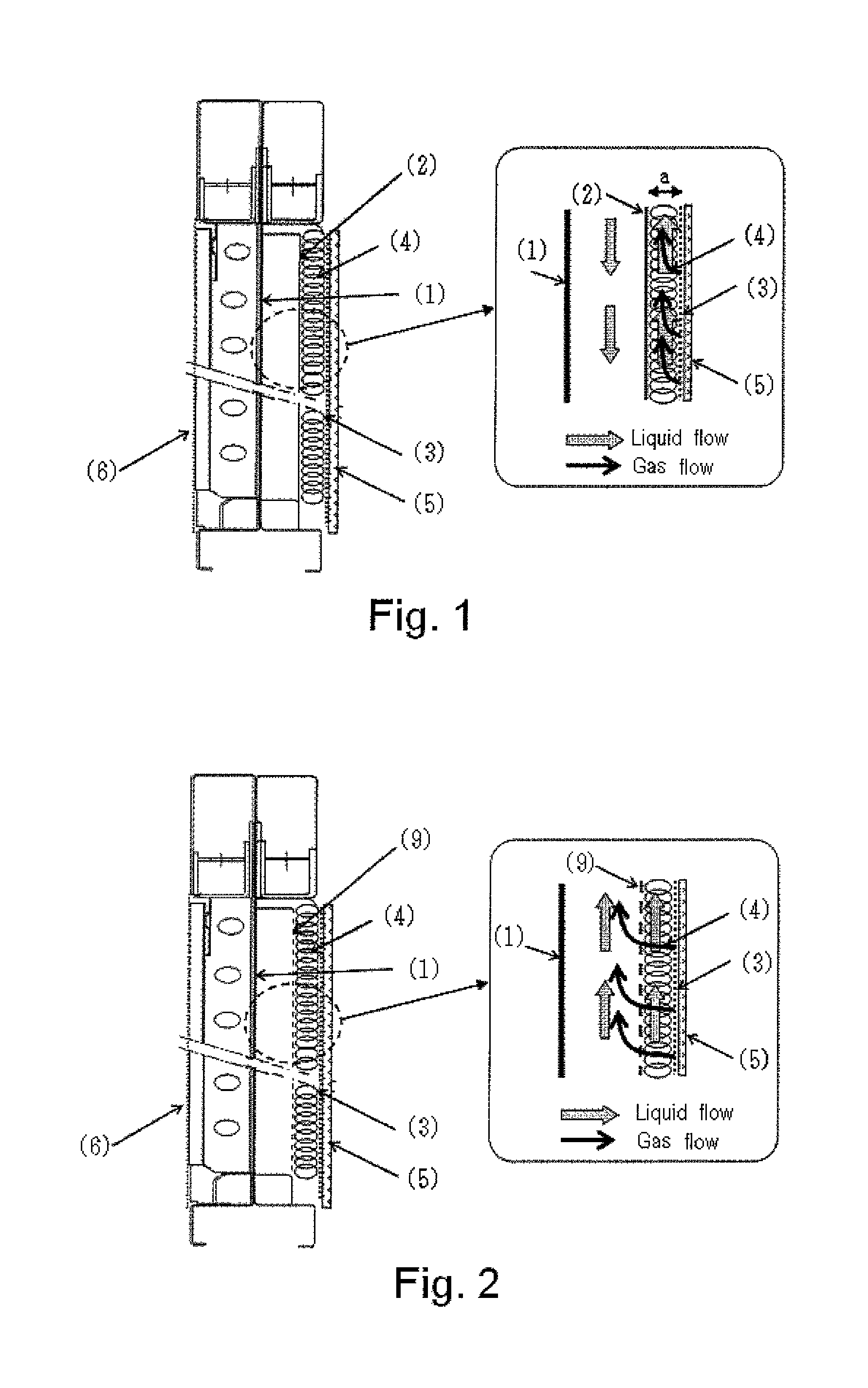

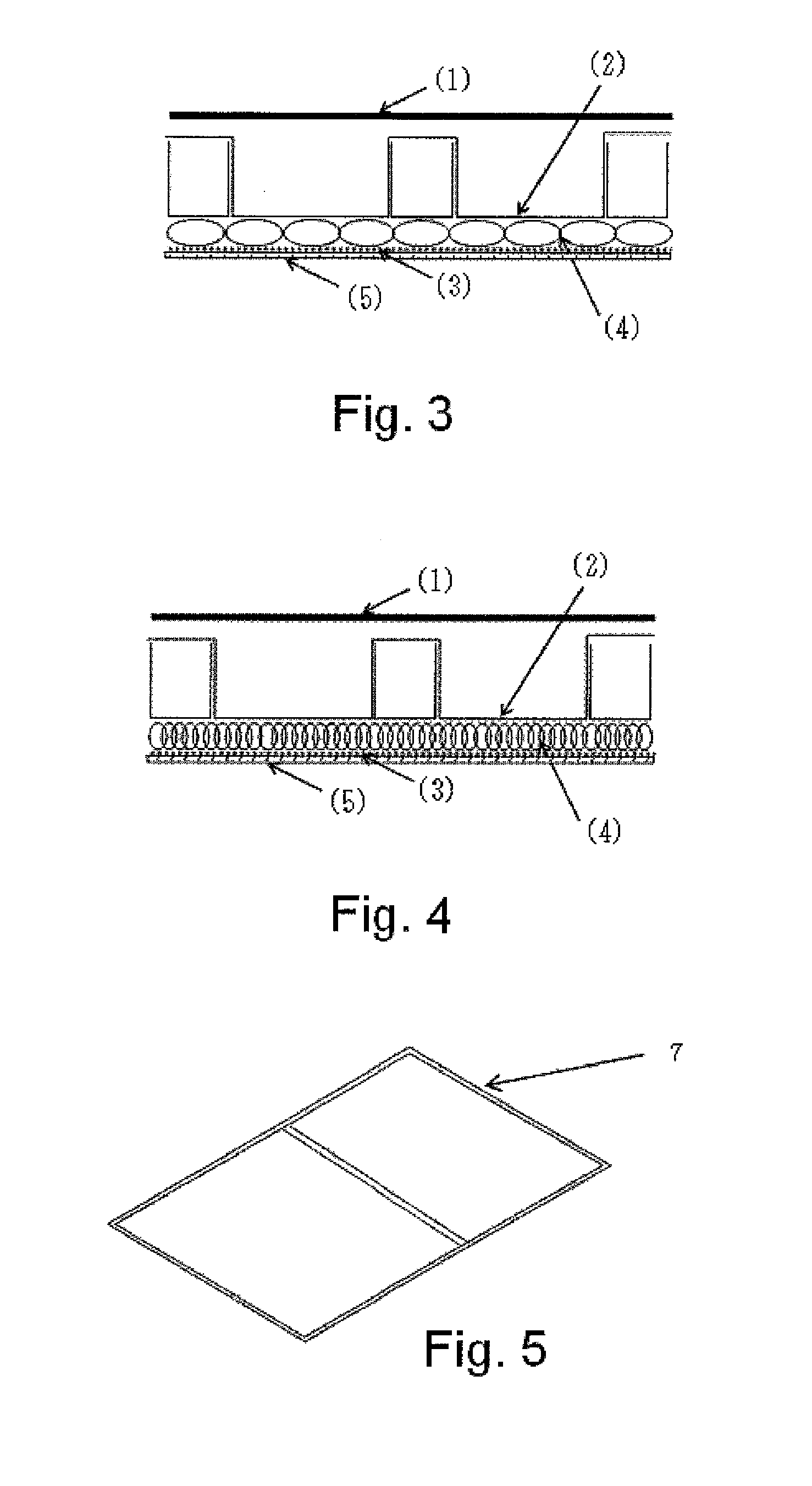

Ion exchange membrane method electrolytic cell

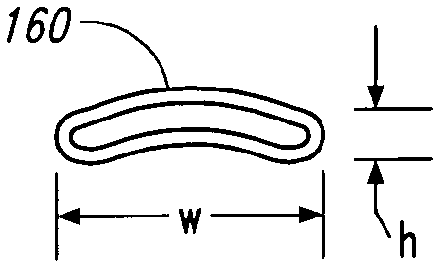

ActiveUS20130299342A1Easy to adjustReduce energy consumptionCellsElectrode shape/formsEngineeringIon-exchange membranes

An ion-exchange membrane method electrolytic cell comprising a coil cushion arranged between a conductive plate and a cathode in a cathode chamber, and further an ion-exchange membrane arranged in contact with the cathode. The conductive plate is not perforated, and the coil cushion is arranged so that its axial direction is in agreement with the vertical direction of electrolytic cell. Preferably the coil cushion is made of a metal coil and has an impact resilience of 7-17 kPa. The cathode preferably has supported electrode catalyst and is made of an expanded metal with strands of 0.1-1.0 mm width and 0.1-1.0 mm thickness, and having SW of 0.5-5.0 mm and LW of 1.0-10 mm, and 48-60% open area. The electrolytic cell is energy-saving, and damage thereof can be avoided over a long period, and elevation of voltage and reduction of current efficiency with time can be minimized.

Owner:TOSOH CORP +1

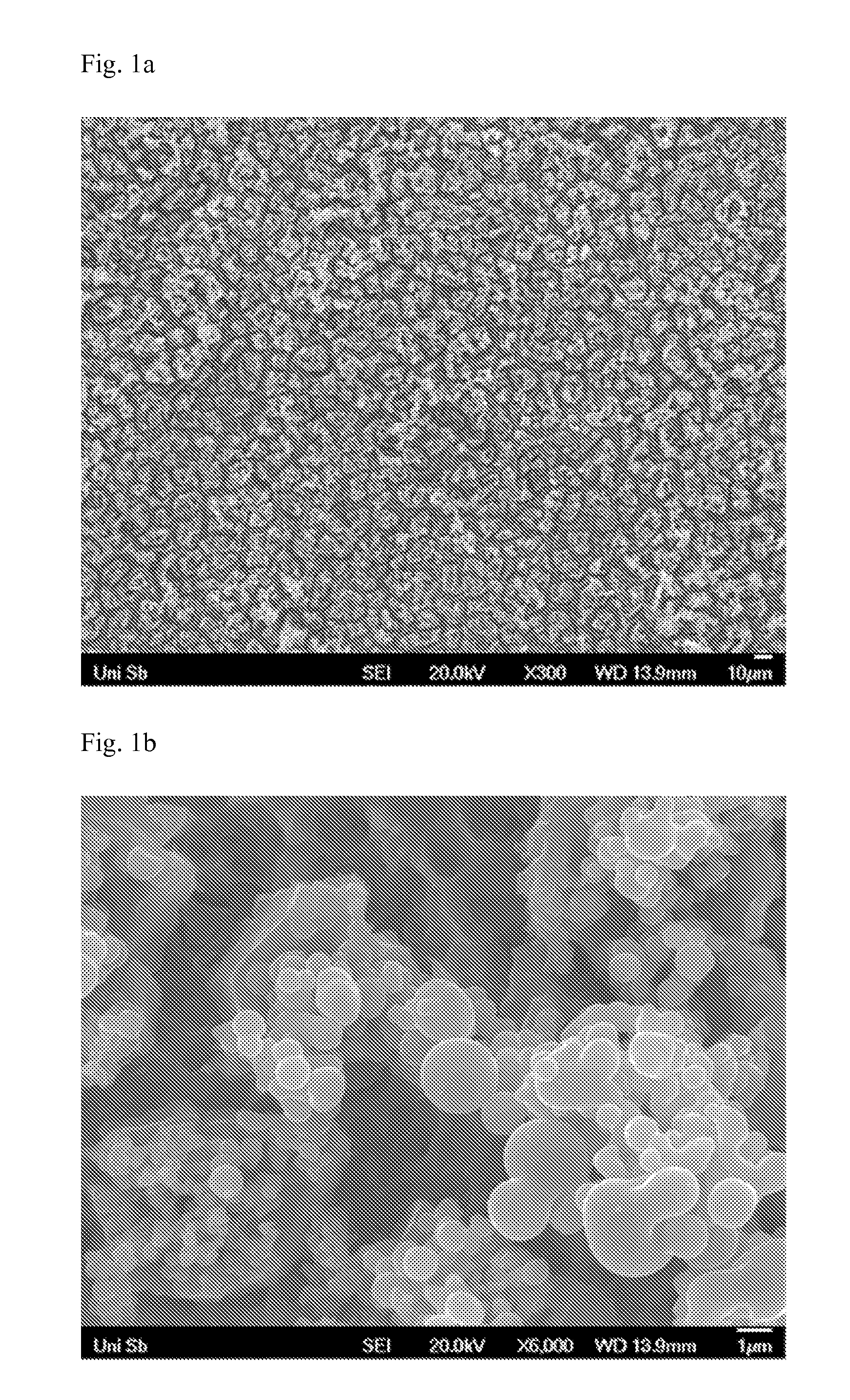

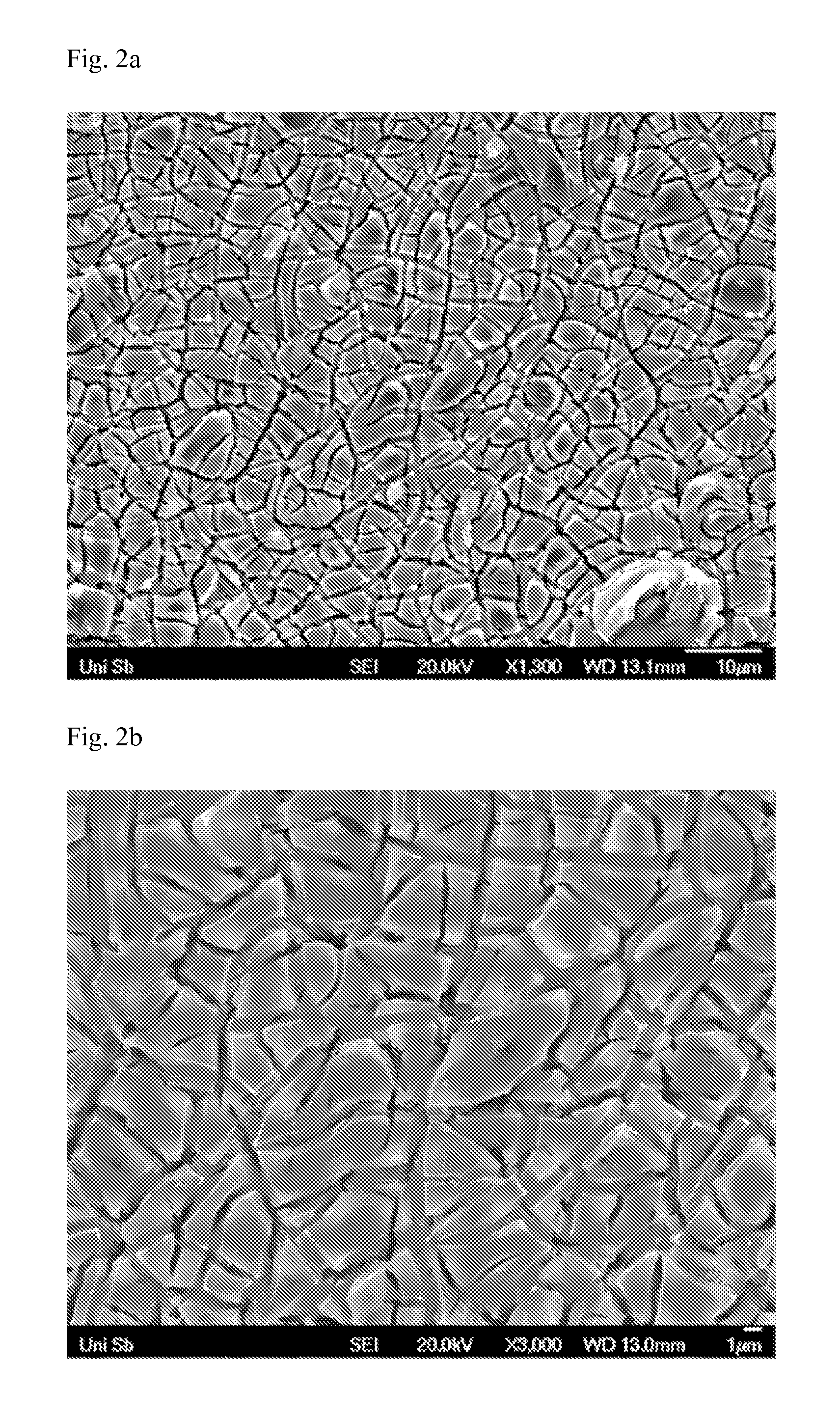

Catalyst coating and process for producing it

InactiveUS20130087461A1Reduce in quantityReduce metal contentDuplicating/marking methodsMultiple component coatingsElectrolysisActive component

An improved catalyst coating comprising electrocatalytically active components based on ruthenium oxide and titanium oxide, especially for use in chloralkali electrolysis, is described. A production process for the catalyst coating and a novel electrode is also described.

Owner:BAYER INTELLECTUAL PROPERTY GMBH

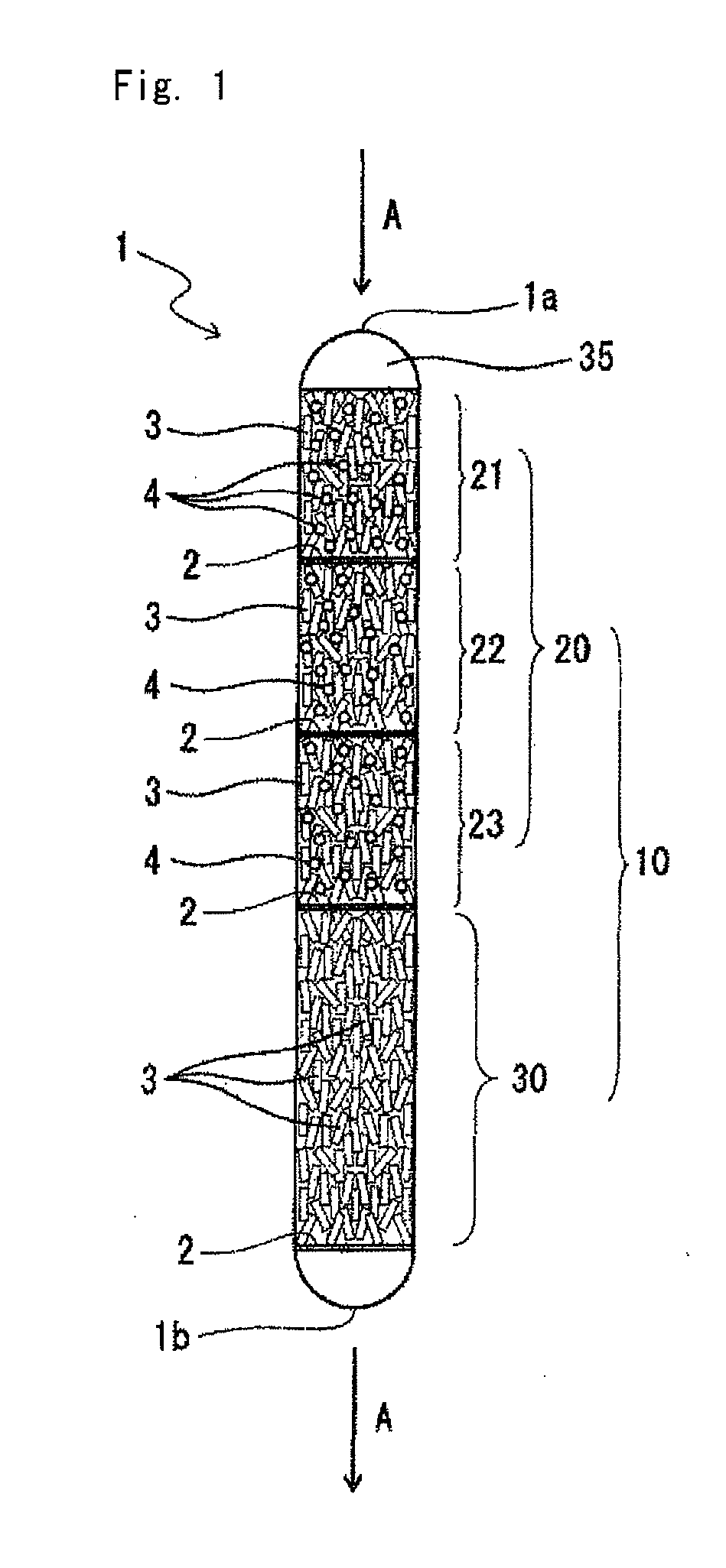

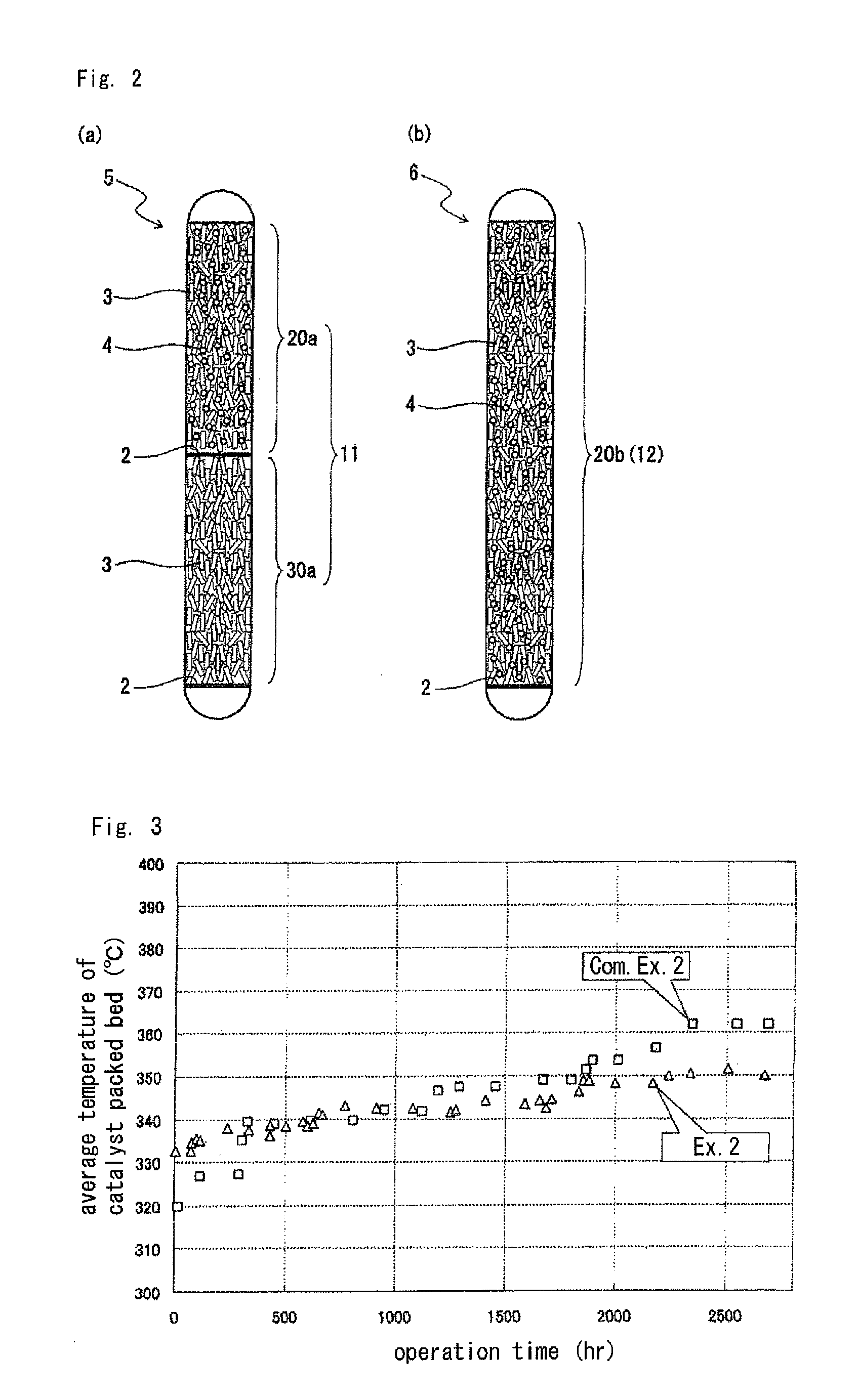

Method for producing chlorine

InactiveCN1344225AEasy to manufactureThe method of making chlorine is beneficialMetal/metal-oxides/metal-hydroxide catalystsPreparation from chloridesReaction zoneOxygen

A process for producing chlorine comprising the step of oxidizing hydrogen chloride in a gas containing hydrogen chloride with a gas containing oxygen in the presence of a catalyst, wherein the oxidation of hydrogen chloride is carried out in at least two reaction zones each comprising a catalyst-packed layer, which are arranged in series, and a temperature in at least one of said reaction zones is controlled with a heat exchange system. According to this process, the stable activity of the catalyst is maintained and chlorine can be stably obtained at a high yield since the excessive hot spot in the catalyst-packed layer is suppressed and the catalyst-packed layer can be effectively used.

Owner:SUMITOMO CHEM CO LTD

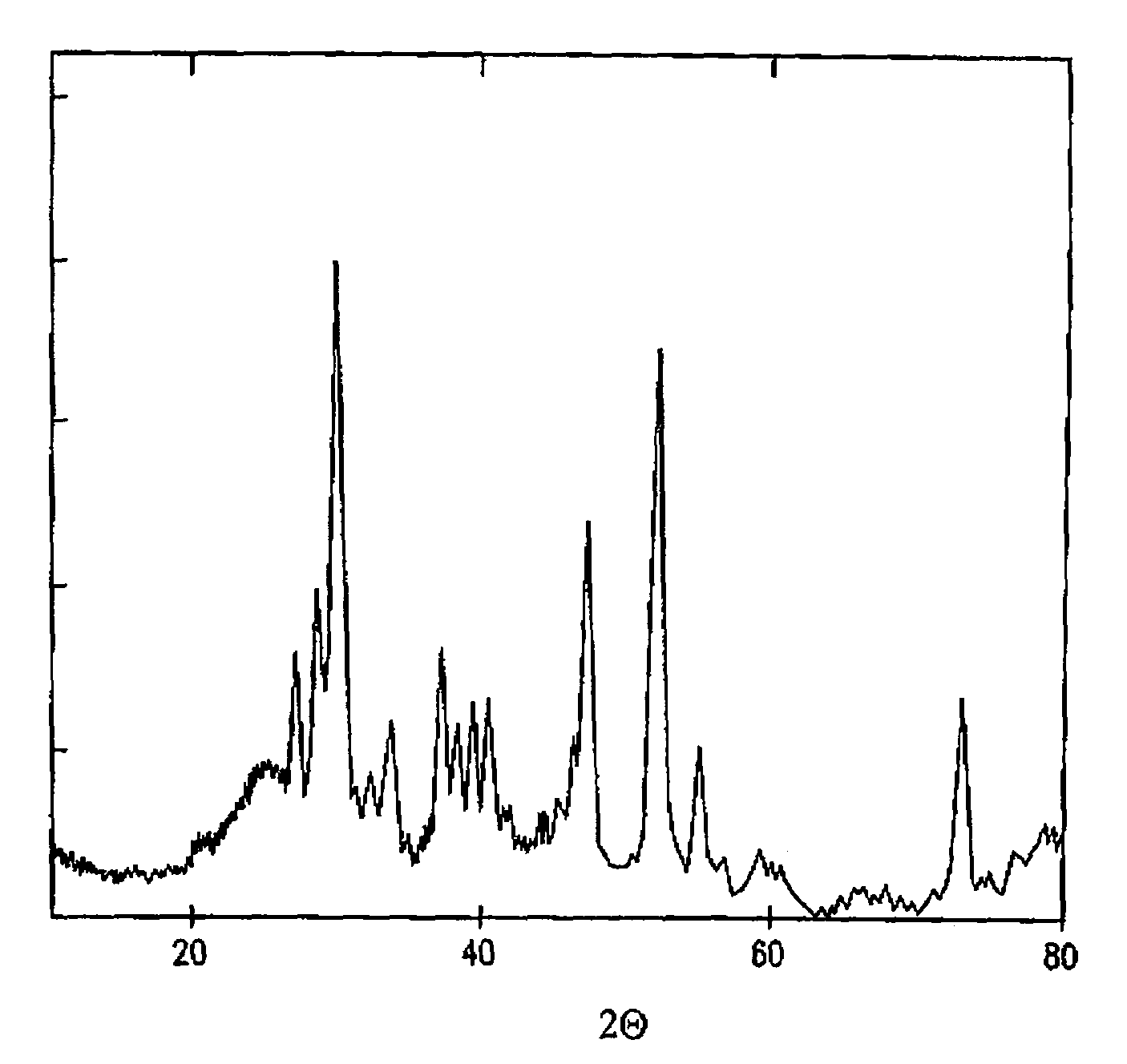

Catalyst for preparing chlorine by oxidation of hydrogen chloride and preparation thereof

InactiveUS20130288884A1Easy to prepareLow priceMolecular sieve catalystsCatalyst activation/preparationRare-earth elementManganese

The present invention relates to a catalyst for producing chlorine by oxidation of hydrogen chloride and a method for preparing the same. The catalyst comprises a support and active ingredients that comprise 1-20 wt % of copper, 0.01-5 wt % of boron, 0.1-10 wt % of alkali metal element(s), 0.1-15 wt % of one or more rare earth elements, and 0-10 wt % of one or more elements selected from magnesium, calcium, barium, manganese, iron, nickel, cobalt, zinc, ruthenium or titanium based on the total weight of the catalyst. The catalyst is prepared by a two-step impregnation method. Comparing with the available catalysts of the same type, the catalyst according to the present invention has greatly improved conversion and stability.

Owner:WANHUA CHEM GRP CO LTD

Regenerative adsorption processes for removing organic components from gas streams

InactiveUS20080250924A1Good energyReduce usageSolidificationChlorine/hydrogen-chloride purificationProduct gasImpurity

Processes are described comprising: providing a crude gas stream having a temperature not exceeding 40° C., the crude gas stream comprising at least one organic impurity; condensing at least a portion of the at least one organic impurity from the crude gas stream at a temperature not exceeding 0° C. to form a prepurified gas stream; and subjecting (at least a portion, preferably substantially all, and more preferably the entirety, of) the prepurified gas stream to adsorption on a first adsorption medium to provide a purified gas stream; wherein the first adsorption medium is subjected to a regeneration comprising: (i) providing a circulating inert gas stream having a temperature of at least 100° C.; (ii) passing the circulating inert gas stream over the first adsorption medium to form an organic impurity-loaded inert gas stream; (iii) cooling the loaded inert gas stream to a temperature not exceeding 40° C.; (iv) condensing at least a portion of the organic impurity from the cooled, loaded inert gas stream to provide a prepurified circulating inert gas stream; subjecting (at least a portion, preferably substantially all, and more preferably the entirety, of) the prepurified circulating inert gas stream to adsorption on a second adsorption medium to provide a purified circulating inert gas stream; and recycling the purified circulating inert gas stream to the circulating inert gas stream.

Owner:BAYER MATERIALSCIENCE AG

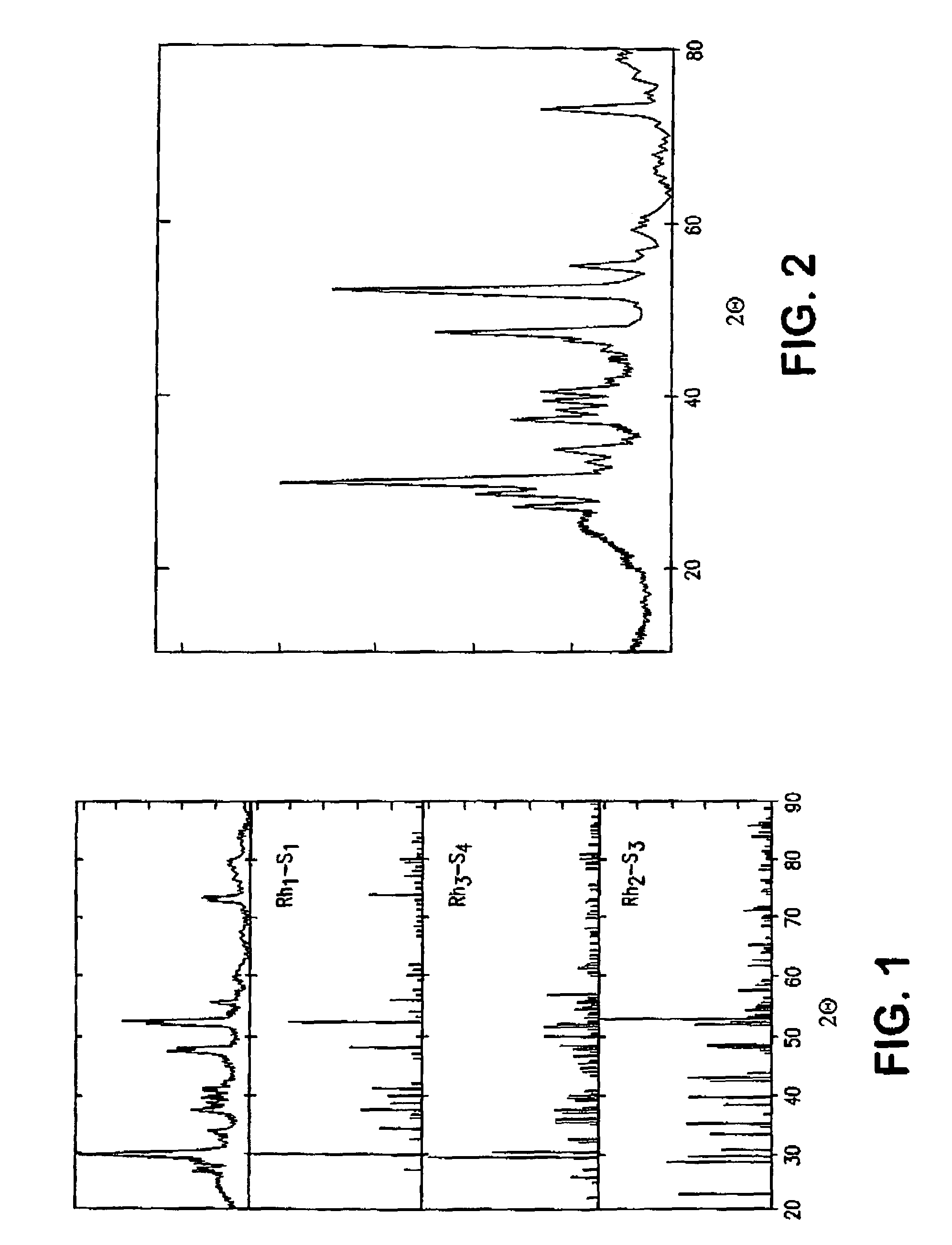

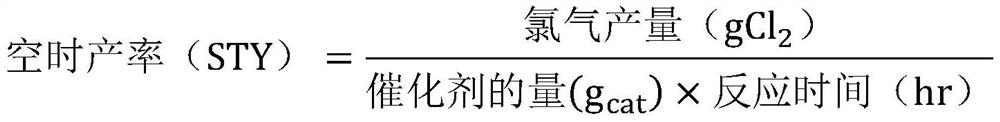

Catalyst and method for producing chlorine by means of a gas-phase oxidation

InactiveUS20140248208A1Improve overall utilizationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCeriumHydrogen chloride

A catalyst material for producing chlorine by the catalytic gas-phase oxidation of hydrogen chloride, wherein the catalyst comprises oxide compounds of cerium as active component components and zirconium dioxide as supporting component and the catalyst h as a particularly high space-time yield with respect to the reactor volume

Owner:COVESTRO DEUTSCHLAND AG

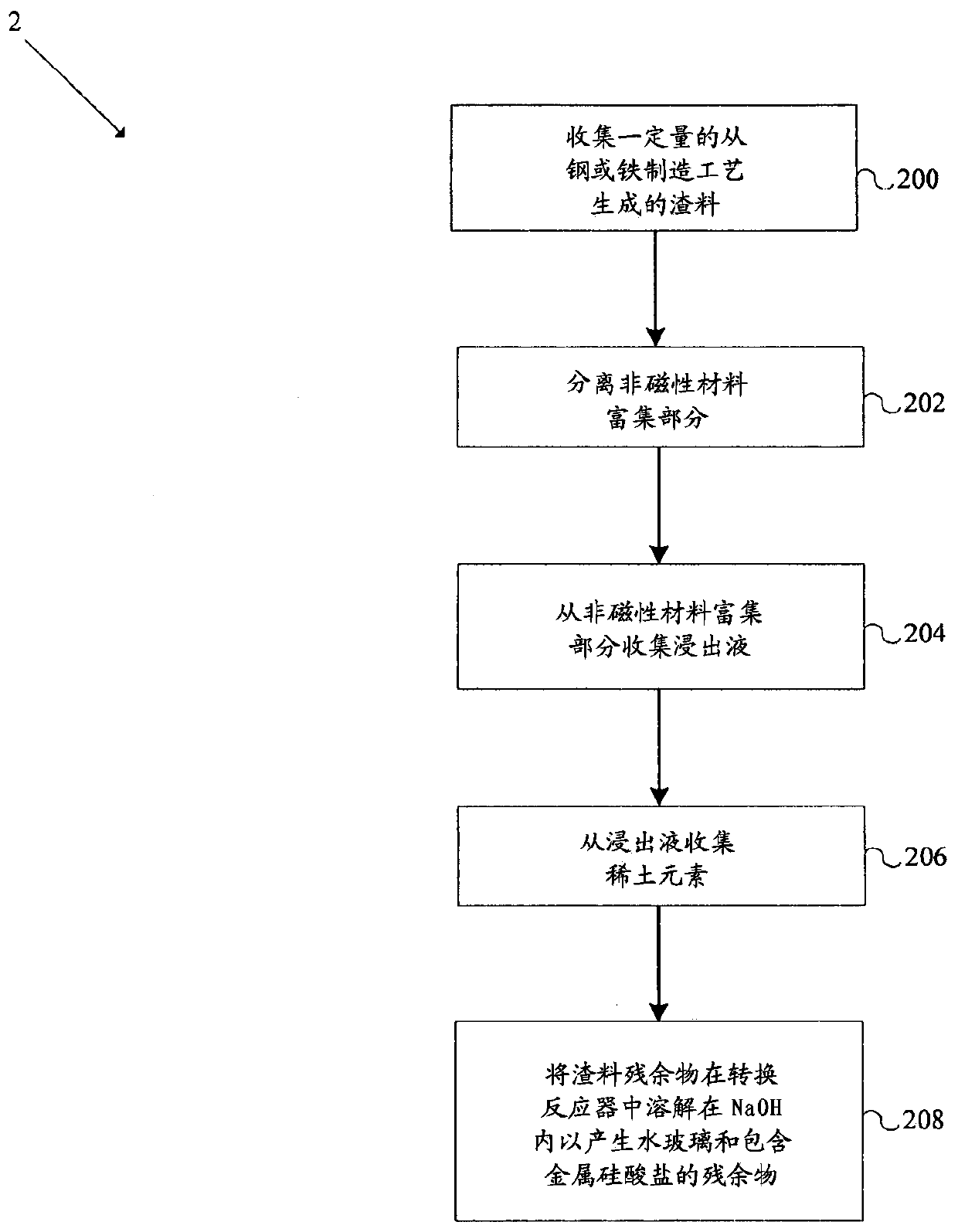

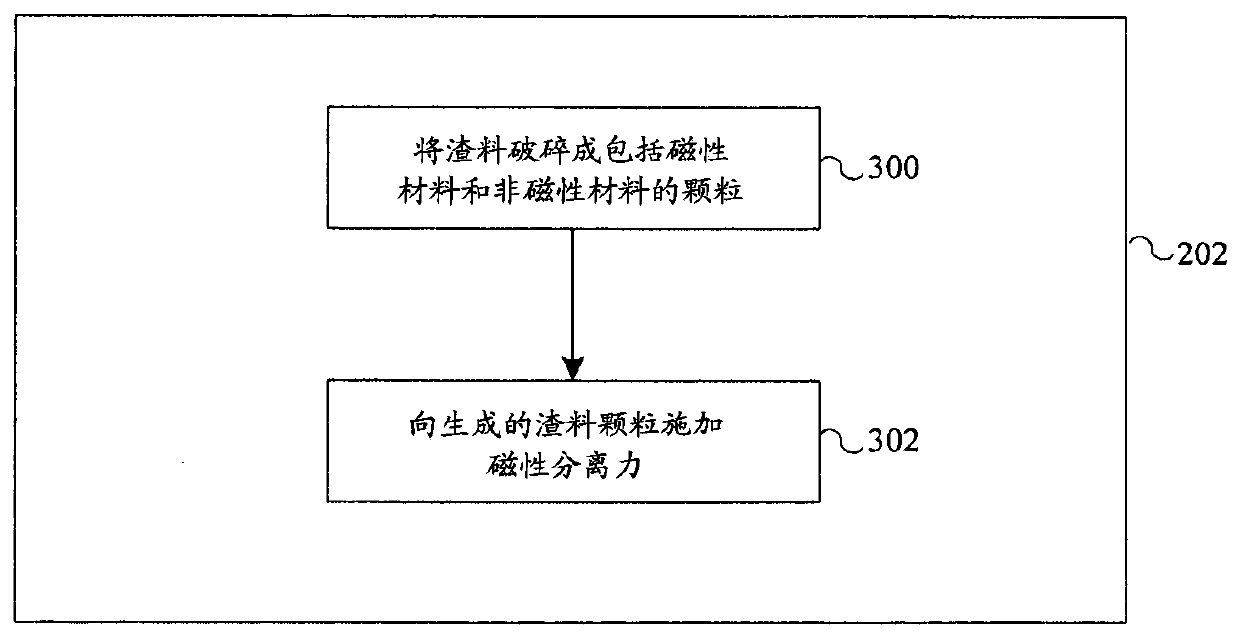

Method and system for recovering products from steel slag

ActiveCN106999947BFully extractedFull responseElectrolysis componentsMagnetic separationRare-earth elementHigh energy

The present invention discloses a system and method for processing slag produced by the iron and steel manufacturing process. The slag is processed to produce a range of valuable industrial products such as metal oxides, metal carbonates, rare earth elements and water glass. The system and method also combine slag processing with CO 2 Storage and flue gas desulfurization integration. Processing slag minimizes the land used to store or bury waste generated by the steel manufacturing process and protects groundwater. In general, solid and gas emissions from industrial processes with high energy consumption and high pollution are greatly reduced, recycled and resourced, thus achieving the goal of nearly zero emissions.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Process for producing chlorine

InactiveUS20110189079A1Metal/metal-oxides/metal-hydroxide catalystsPreparation from chloridesSulfurDiluent

Disclosed is a process for producing chlorine, which makes it possible to successfully continue an oxidation reaction, even if sulfur component-containing hydrogen chloride is used. This process comprises a step of feeding sulfur component-containing hydrogen chloride and oxygen into a reaction tube 1 comprising a catalyst packed bed 10, to thereby oxidize the hydrogen chloride to produce chlorine, wherein the catalyst packed bed 10 includes an alumina-mixed catalyst packed bed 20 formed of a mixture of a catalyst 3 with alumina (or a diluent 4), and wherein the BET specific surface area of the alumina is from 10 to 500 m2 / g. Preferably, the alumina is γ-alumina and / or θ-alumina.

Owner:SUMITOMO CHEM CO LTD

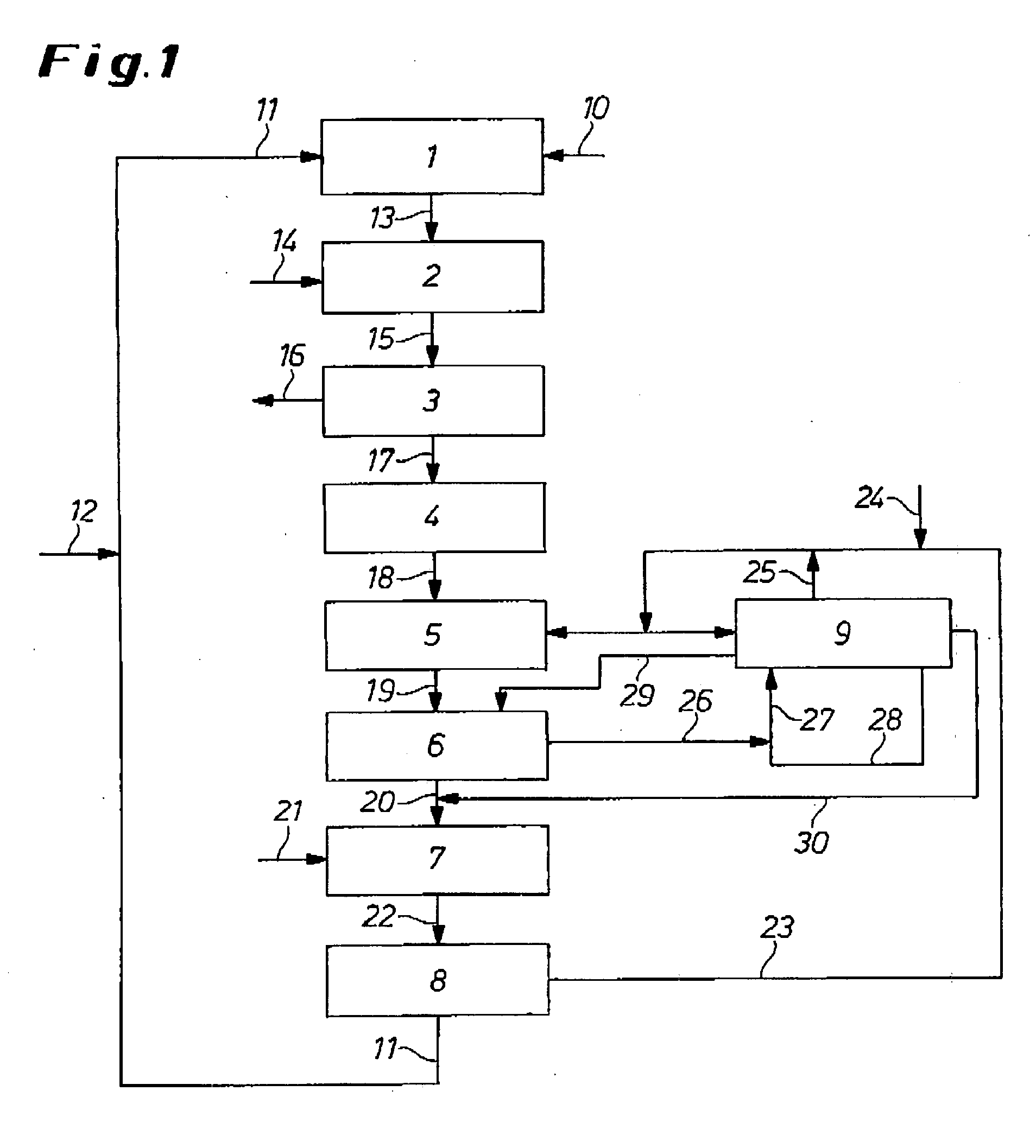

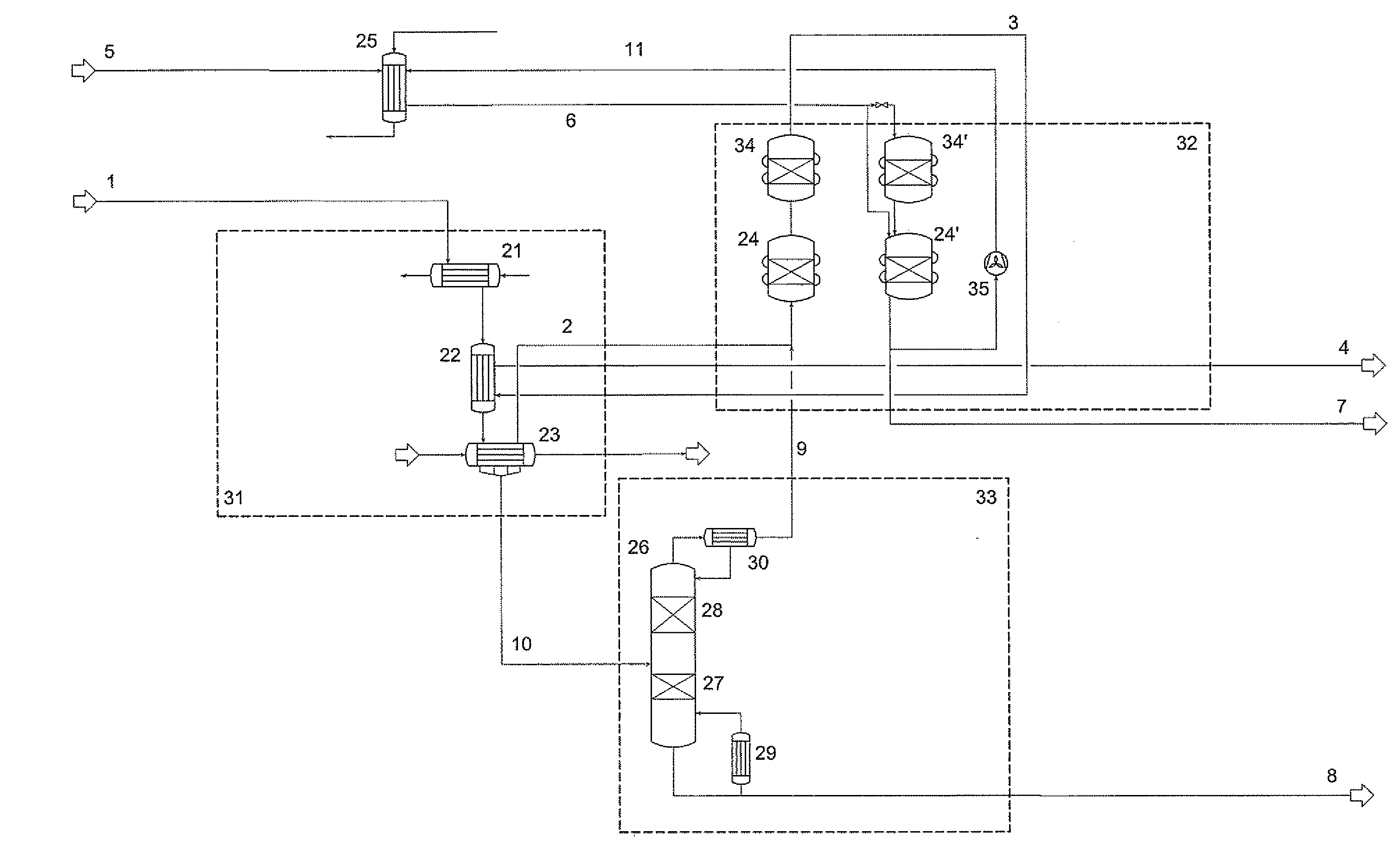

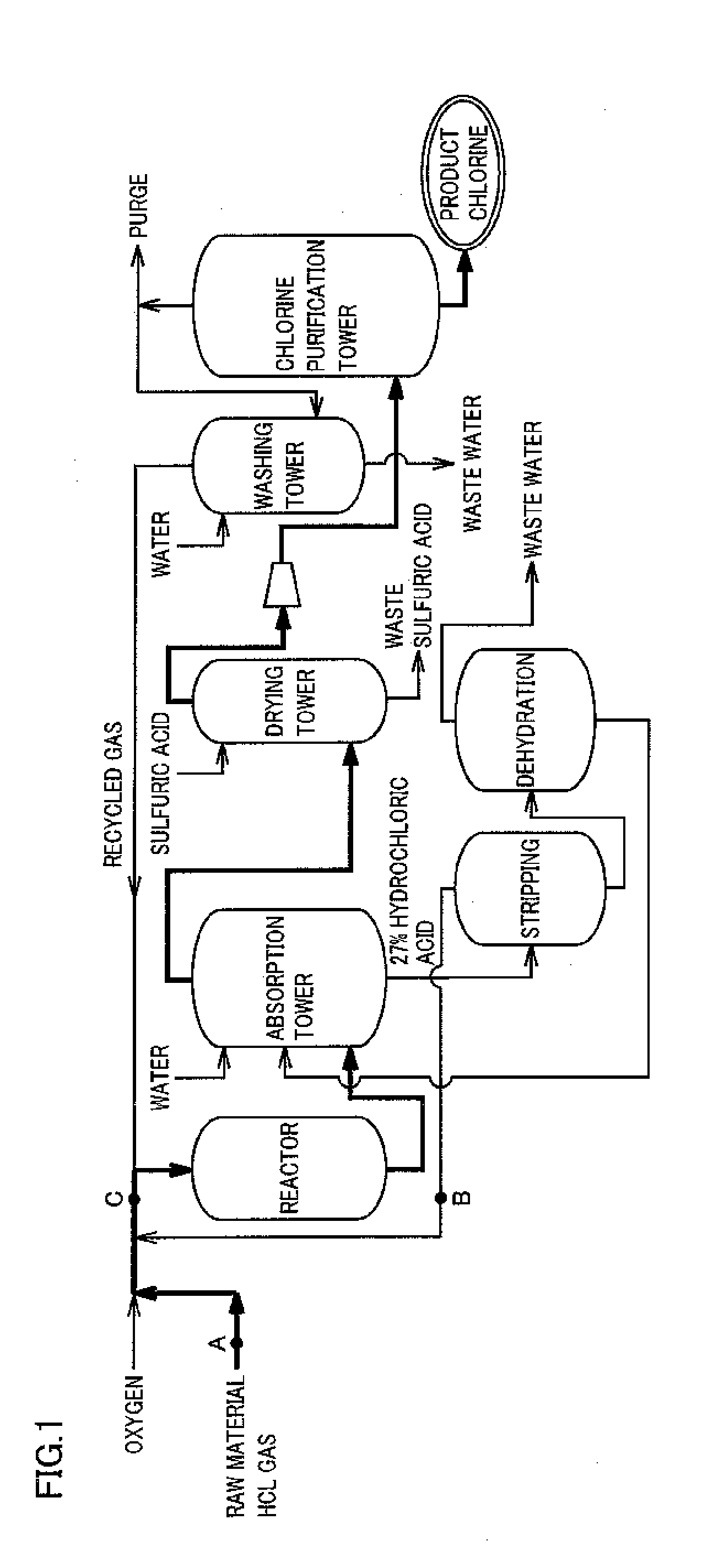

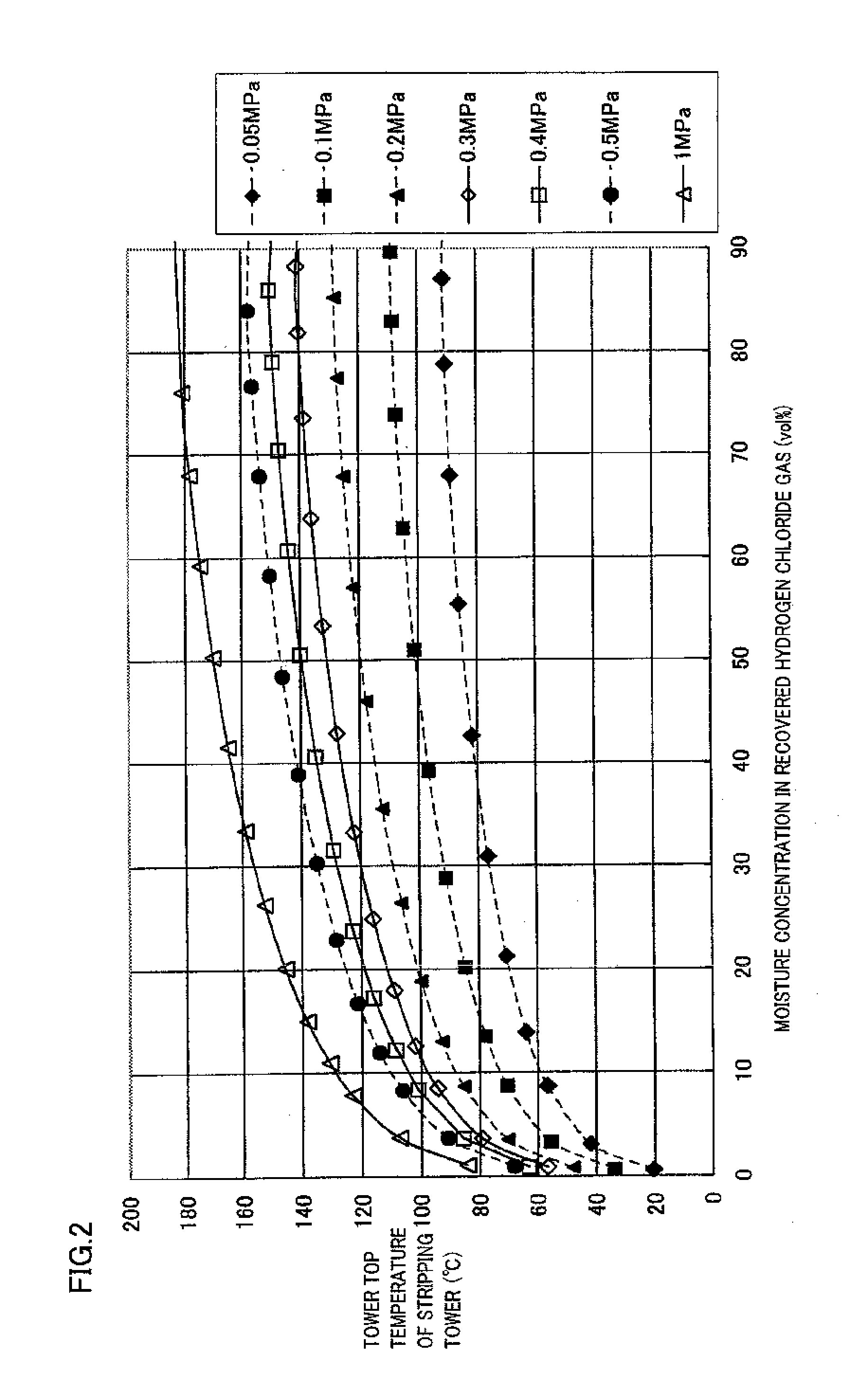

Method for producing chlorine

InactiveUS20110256050A1High yieldEfficient separationChlorine/hydrogen-chloride purificationPreparation from chloridesOxygenEthyl Chloride

An object of the present invention is to provide a novel method for producing chlorine, by which it is possible to remove impurities contained with hydrogen chloride in a raw material gas and further to recover unreacted hydrogen chloride after an oxidation reaction efficiently in a method for producing chlorine by oxidizing hydrogen chloride. The method of the present invention for producing chlorine includes [1] an oxidation step of oxidizing hydrogen chloride in a raw material gas containing the hydrogen chloride and impurities with a gas containing oxygen, thereby obtaining a gas containing chlorine, water, unreacted hydrogen chloride, and unreacted oxygen; [2] an absorption step of bringing the gas containing chlorine, water, unreacted hydrogen chloride, and unreacted oxygen obtained in the oxidation step into contact with an absorbent liquid including water or aqueous hydrochloric acid or cooling the gas, thereby recovering unreacted hydrogen chloride in the form of a solution containing hydrogen chloride and water as main components and simultaneously obtaining a gas containing chlorine and unreacted oxygen as main components; and [3] a stripping step of distilling the solution obtained in the absorption step, thereby obtaining a gas containing hydrogen chloride as a main component, wherein the gas obtained in the stripping step, which contains hydrogen chloride as a main component and contains 5 to 50% by volume of water, is recovered and mixed with the raw material gas.

Owner:SUMITOMO CHEM CO LTD

Electrolytic cell

ActiveUS9476130B2Easy to adjustReduce energy consumptionCellsEnergy inputPower flowIon-exchange membranes

An ion-exchange membrane method electrolytic cell comprising a coil cushion arranged between a conductive plate and a cathode in a cathode chamber, and further an ion-exchange membrane arranged in contact with the cathode. The conductive plate is not perforated, and the coil cushion is arranged so that its axial direction is in agreement with the vertical direction of electrolytic cell. Preferably the coil cushion is made of a metal coil and has an impact resilience of 7-17 kPa. The cathode preferably has supported electrode catalyst and is made of an expanded metal with strands of 0.1-1.0 mm width and 0.1-1.0 mm thickness, and having SW of 0.5-5.0 mm and LW of 1.0-10 mm, and 48-60% open area. The electrolytic cell is energy-saving, and damage thereof can be avoided over a long period, and elevation of voltage and reduction of current efficiency with time can be minimized.

Owner:TOSOH CORP +1

Processes for removing organic components from gases containing hydrogen chloride

ActiveUS7837767B2Reduce lossesSolidificationChlorine/hydrogen-chloride purificationHydrogen chlorideImpurity

Owner:COVESTRO DEUTSCHLAND AG

Method for producing chlorine

InactiveCN1344224AEasy to manufactureThe method of making chlorine is beneficialMetal/metal-oxides/metal-hydroxide catalystsPreparation from chloridesFixed bedProduct gas

In a method for producing chlorine comprising oxidizing hydrogen chloride present in a gas containing the hydrogen chloride using a gas containing oxygen in a fixed bed reaction system having a reaction region comprising catalyst-packed layer, an improvement which comprises conducting the oxidation reaction with a superficial linear velocity of the gas of 0.70 to 10 m / sec is disclosed. This method enables the inhibition of formation of excess hot spots and effective utilization of the catalyst-packed layers, which results in maintaining stable activity of the catalyst and in the production of chlorine in high yield with good stability.

Owner:SUMITOMO CHEM CO LTD

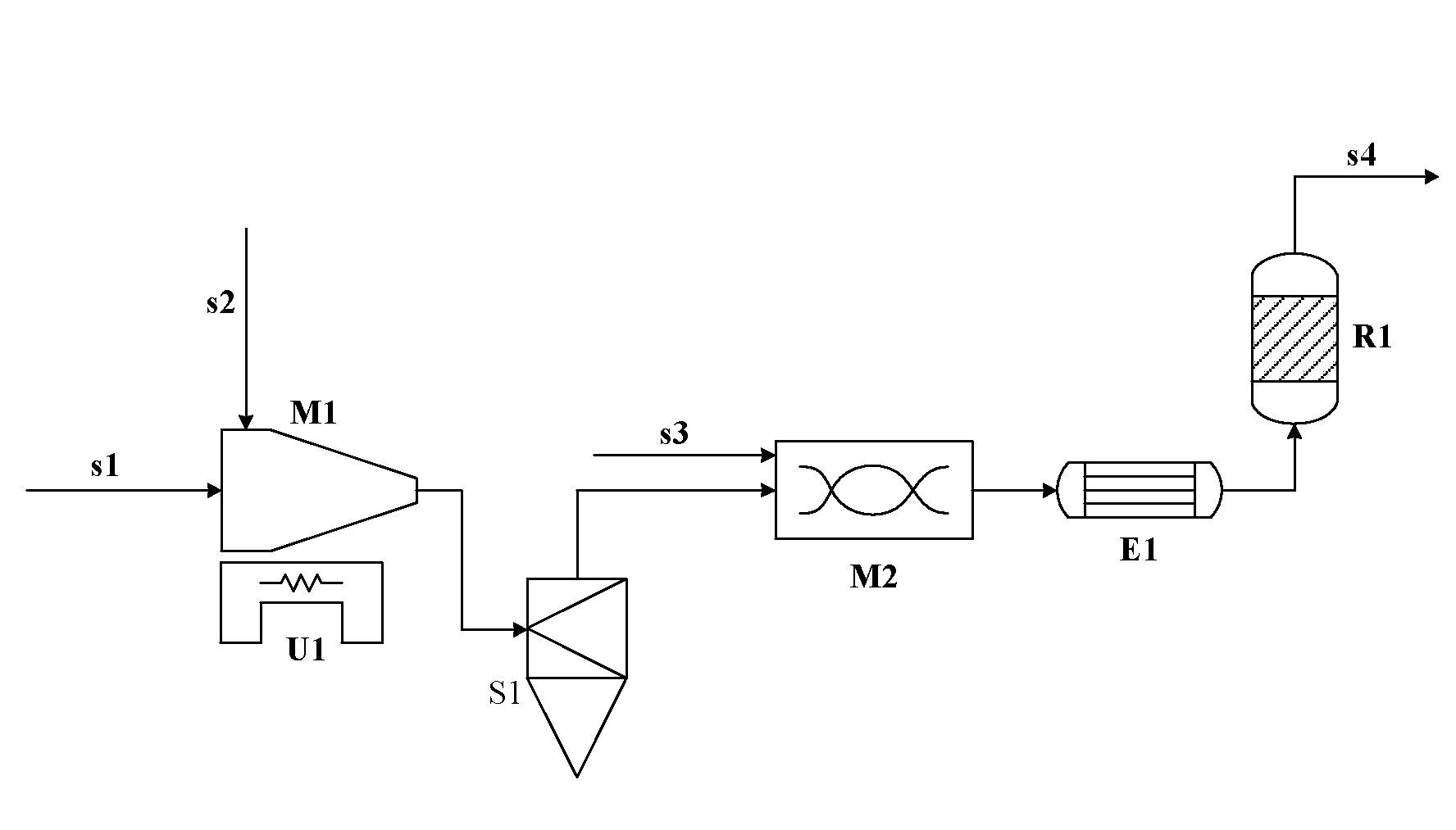

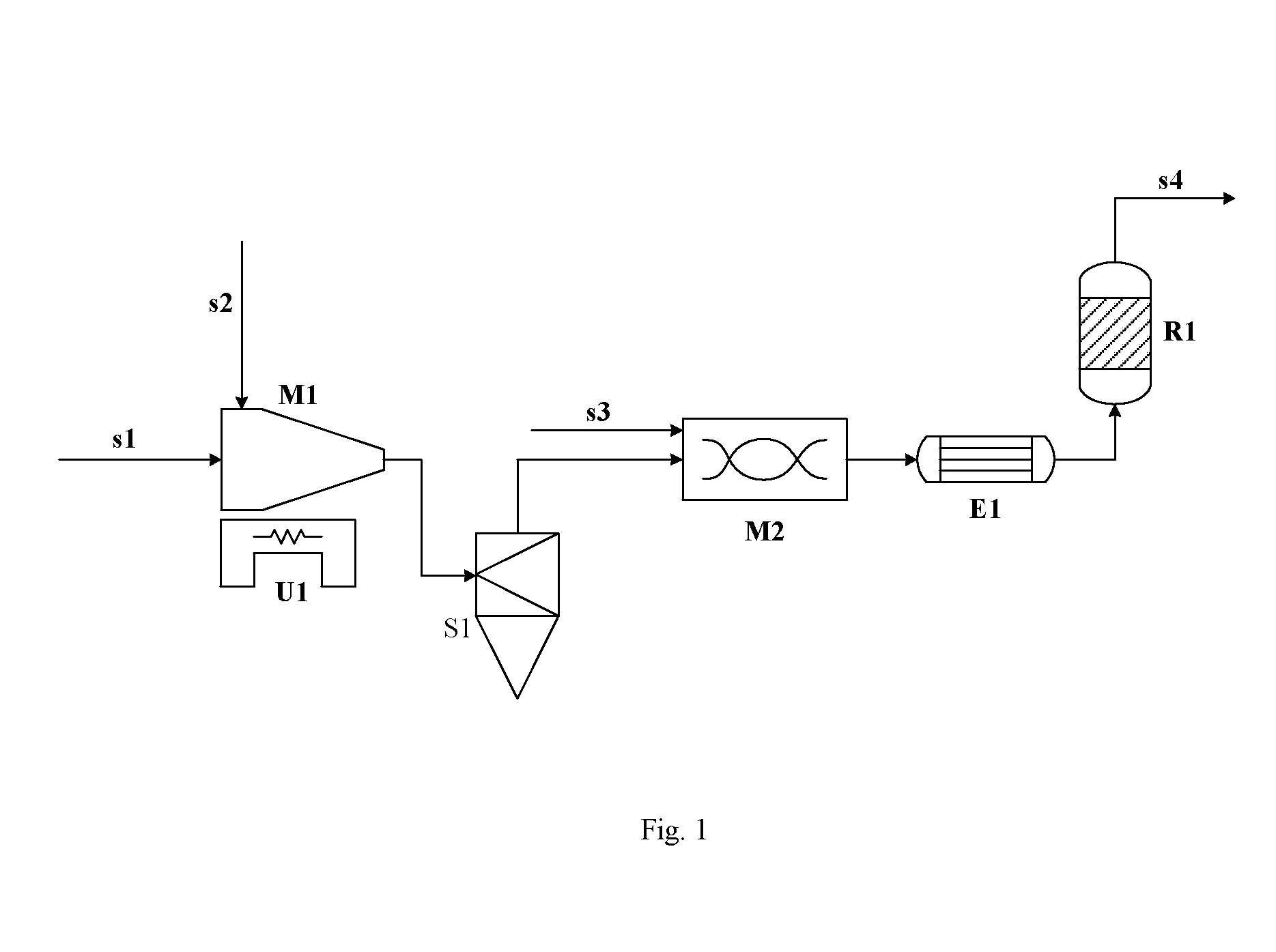

Process of Producing Chlorine Gas by Catalytic Oxidation of Hydrogen Chloride

InactiveUS20150037243A1Improve responseImprove reaction speedChlorine/hydrogen-chloride purificationPreparation from chloridesUltrasound - actionCatalytic oxidation

A process of producing chlorine gas by catalytic oxidation of hydrogen chloride including: incorporating an oxidizing agent such as ozone, hydrogen peroxide solution etc. into a gas stream of hydrogen chloride containing impurities, conducting oxidation pretreatment of the gas stream under the action of ultrasonic wave, such that the impurities contained in the gas stream are oxidized; wherein the oxidizing agent does not generate additional or new impurities in the reaction system, where the gas stream obtained after the oxidation pretreatment is allowed to pass through a separating device wherein the oxidized impurities in the form of liquid and / or the oxidized impurities in the form of solid are removed from the gas stream so as to obtain a purified gas stream of hydrogen chloride, and thereafter the purified gas stream of hydrogen chloride is well mixed with a gas stream containing molecular oxygen, the resultant gas mixture is preheated to a reaction temperature, and then catalytically oxidized to produce chlorine gas, thus by means of oxidation pretreatment and separation, the process can remove efficiently the sulfur-containing impurities, the halogen-containing impurities, hydrocarbon impurities and the like from the gas stream of hydrogen chloride, and does not generate additional impurities.

Owner:WANHUA CHEM GRP CO LTD

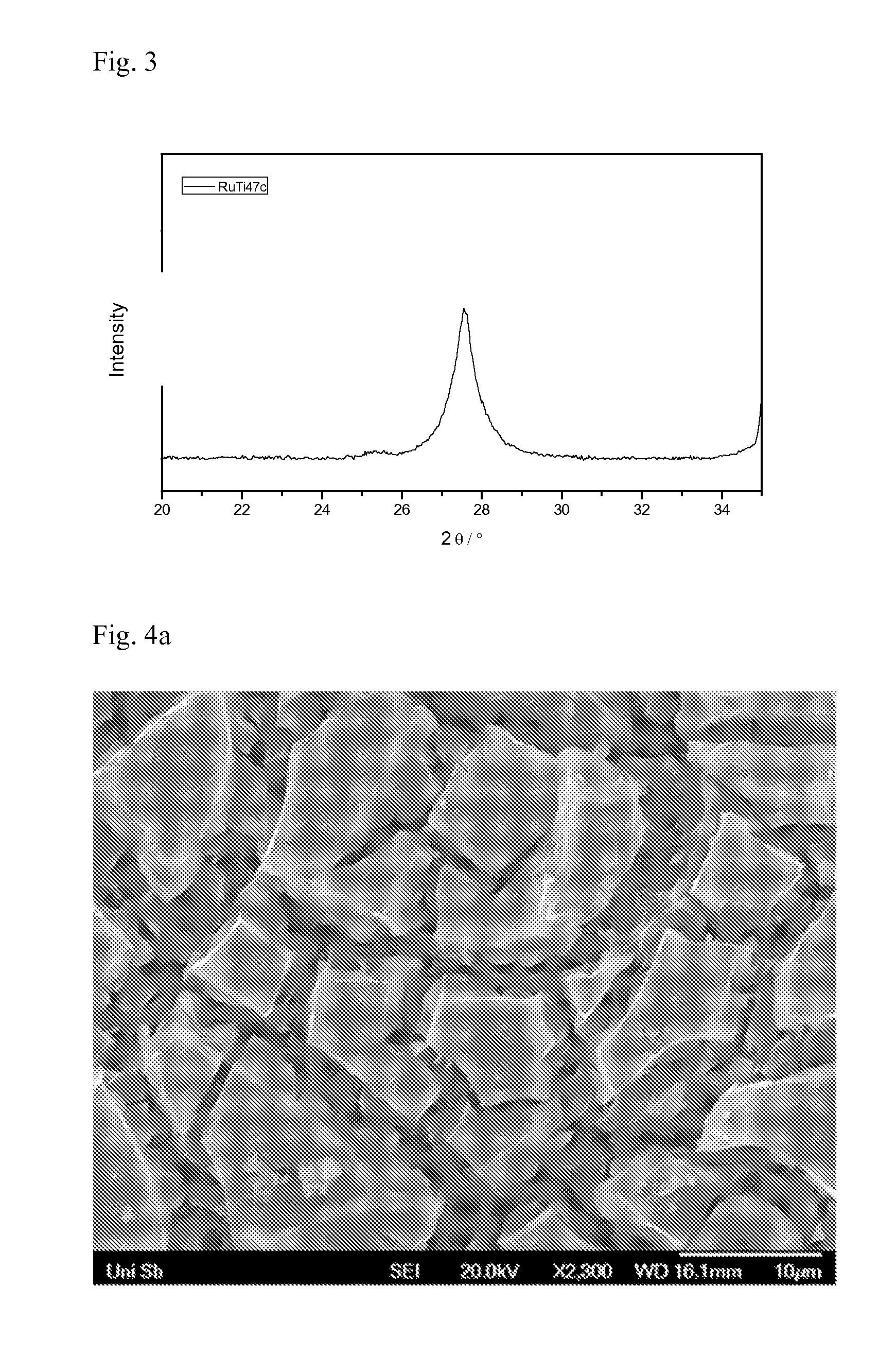

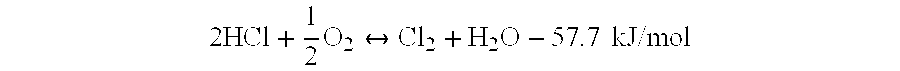

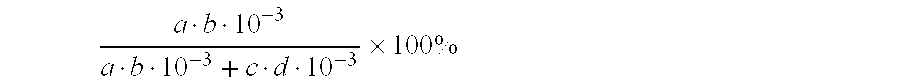

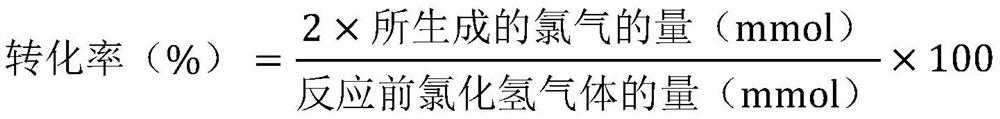

Method for manufacturing ruthenium oxide-supported catalyst for preparing chlorine and catalyst manufactured thereby

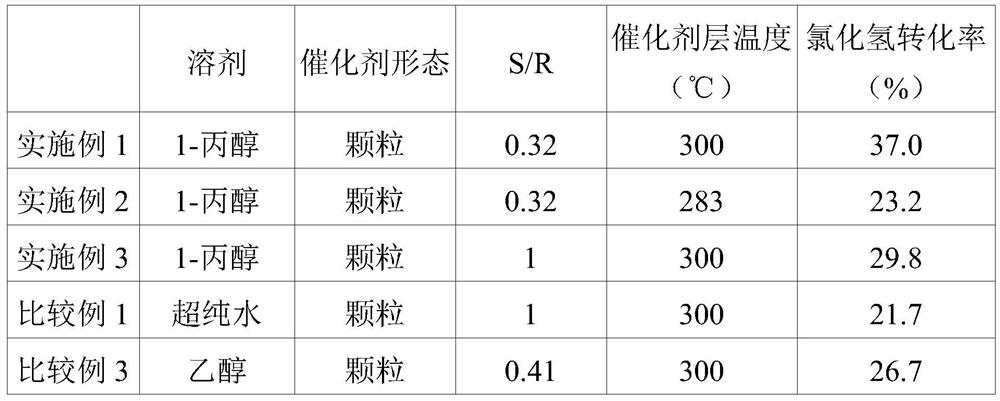

PendingCN113242767AGood for scaling upScale upCatalyst activation/preparationCalcinationPtru catalystOrganic solvent

The present invention relates to a method for manufacturing a ruthenium oxide-supported catalyst for preparing chlorine and, more specifically, to a method for manufacturing a catalyst and a catalyst manufactured thereby, wherein the catalyst contains a ruthenium ingredient of which the support level on the outer surface of the support is significantly improved, and the use of the catalyst in chlorine production can provide a high conversion rate of chlorine even at a low reaction temperature. Provided according to an embodiment of the present invention is a method for manufacturing a ruthenium oxide-supported catalyst for preparing chlorine, the method comprising the steps of: (a) dissolving a ruthenium compound in an organic solvent to prepare a solution and supporting same on at least one support selected from among titania and alumina; (b) drying; and (c) sintering. According to an embodiment of the present invention, specifically, a simplified process is provided, wherein a catalyst containing ruthenium oxide only at the outer surface layer of a titania support can be prepared without an alkaline pretreatment, thereby exhibiting an advantageous effect in terms of scale-up.

Owner:HANWHA SOLUTIONS CORP

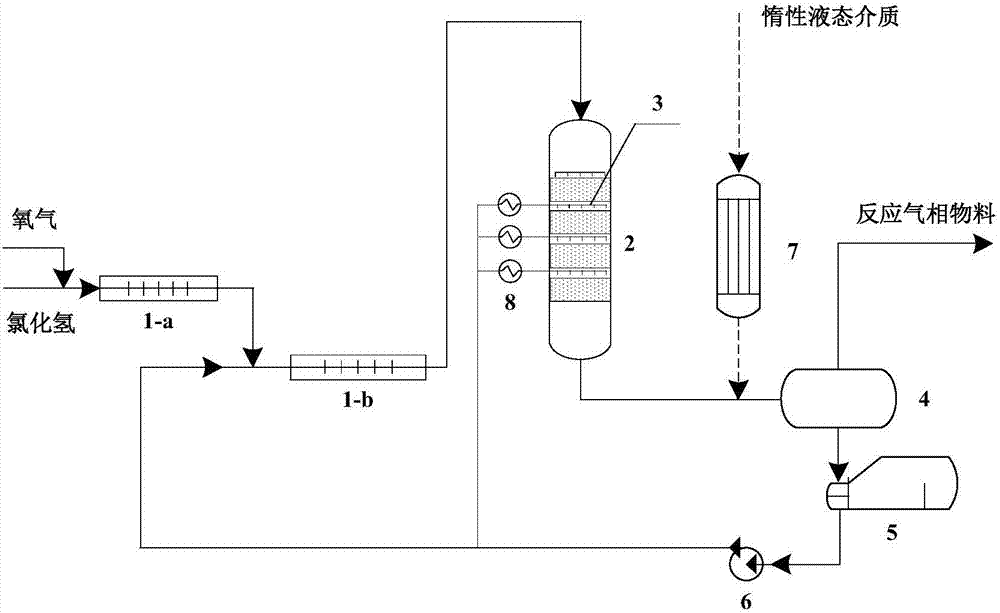

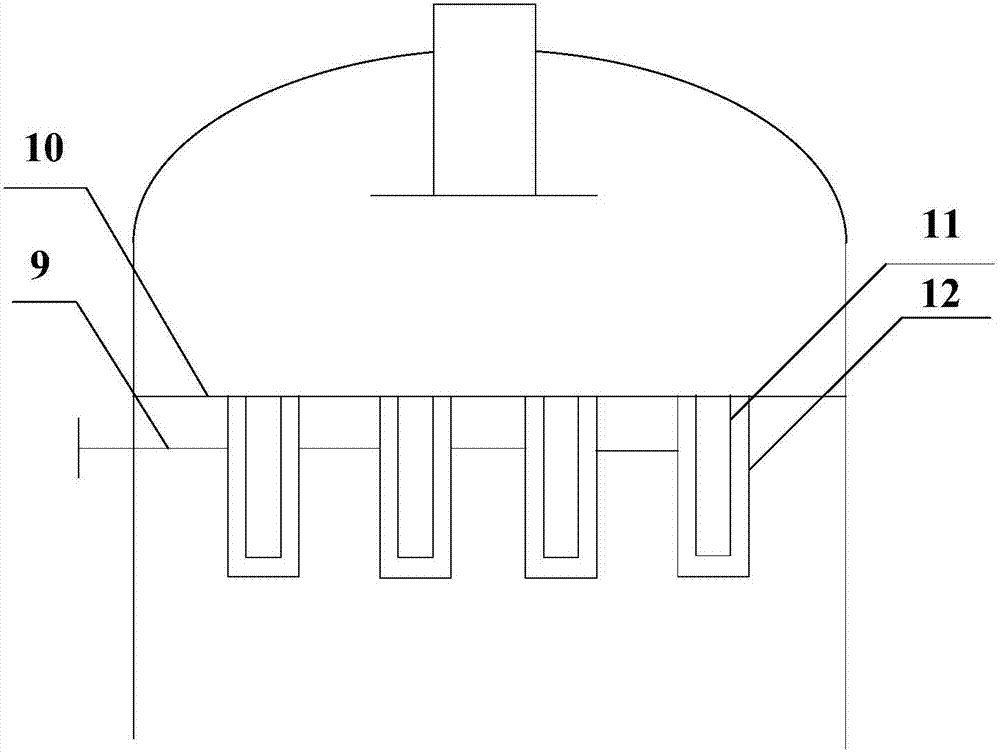

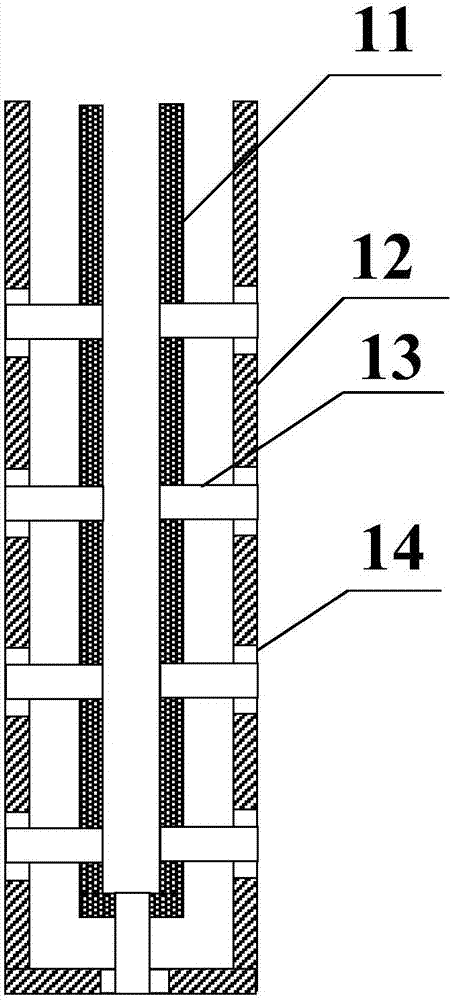

Method for preparing chlorine by performing hydrogen chloride oxidation by trickle bed reactor

ActiveCN107117580AReduce backmixingModerate responseCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsLiquid mediumGas phase

The invention discloses a method for preparing chlorine by performing hydrogen chloride oxidation by a trickle bed reactor. The method comprises the following steps: mixing airflow containing molecular oxygen and airflow gaseous phase containing hydrogen chloride, mixing the mixture and a high-temperature inert liquid medium, introducing the preheated mixed materials into the trickle bed reactor, and performing oxychlorination reaction under the action of a catalyst to prepare chlorine. Meanwhile, the inert liquid mediums are injected into different positions of the axial direction of the trickle bed reactor, and axial temperature gradient is formed in the reactor, so that the conversion rate is increased. By the method, the mass transfer and heat transfer effects of the catalytic reaction process can be effectively enhanced, the controllability of temperature distribution in the reactor is guaranteed, the axial temperature gradient is formed in the reactor, the reaction heat utilization efficiency is improved, the reaction conversion rate is increased, and use of reactor materials is reduced.

Owner:WANHUA CHEM GRP CO LTD

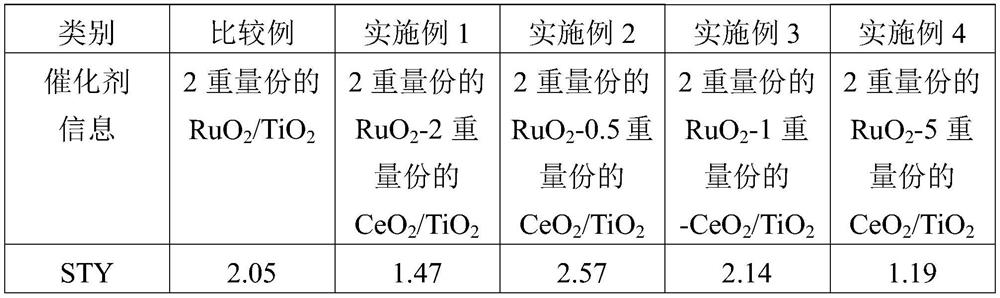

Catalyst for electrochemical reduction of oxygen

ActiveUS7956004B2Promotes the instantaneous metathesis of the metal ions and the thionic partInhibition formationActive material electrodesEnergy inputSingle crystalSulfide

The invention relates to a sulphide catalyst for electrochemical reduction of oxygen particularly stable in chemically aggressive environments such as chlorinated hydrochloric acid. The catalyst of the invention comprises a noble metal sulphide single crystalline phase supported on a conductive carbon essentially free of zerovalent metal and of metal oxide phases, obtainable by reduction of metal precursor salts and thio-precursors with a borohydride or other strong reducing agent.

Owner:IND DE NORA SPA

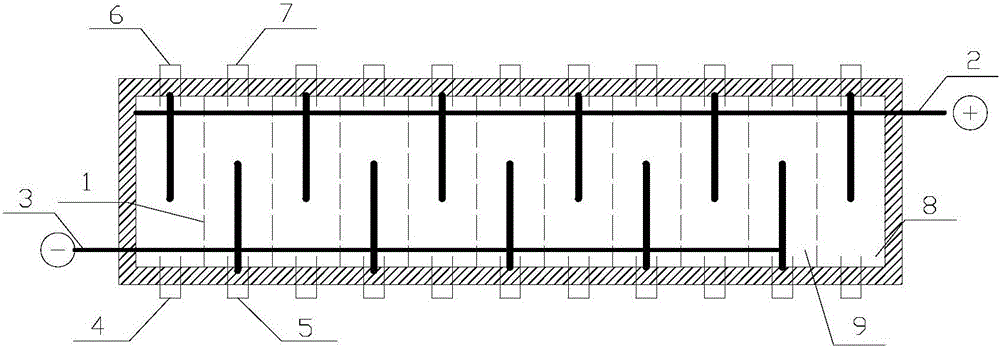

Synchronous production process for manganese metal and chlorine disinfectant through electrolytic cell

InactiveCN105734608AImprove utilization efficiencyReduce energy consumptionPhotography auxillary processesDiaphragmsDisinfectantManganese

The invention relates to a synchronous production process for manganese metal and a chlorine disinfectant through an electrolytic cell. A constant-current electrolysis technology is adopted, and therefore synchronous production of manganese metal deposition and chlorine disinfectant generation can be achieved. The electrolytic cell comprises a plurality of unit electrolytic cell bodies, and anion-exchange membranes and sealing gaskets are arranged between the unit electrolytic cell bodies. The synchronous production process has the beneficial effects that due to the fact that the anion-exchange membranes are used, it is guaranteed that needed products can be prepared by synchronously using cathode currents and anode currents; and in addition, the purity of cathode and anode products can reach the industrial standard, and the efficiency of energy utilization is greatly improved. As for the electrolytic manganese industry, it means that the energy consumption of the synchronous production process is reduced by more than one time.

Owner:WUHAN UNIV

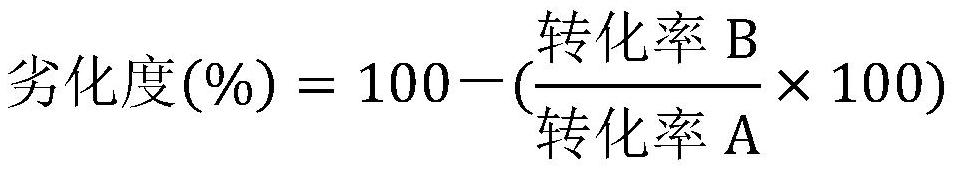

Hydrogen chloride oxidation reaction catalyst for preparing chlorine, and preparation method therefor

PendingCN113164924AIncreased durabilityHigh catalytic activityHeterogenous catalyst chemical elementsCatalyst activation/preparationPtru catalystPhysical chemistry

The present invention relates to a catalyst for obtaining chlorine (Cl2) through the oxidation reaction of hydrogen chloride (HCl) and, more specifically, to: an oxidation reaction catalyst for preparing Cl2 from HCl by the addition of a second hetero-material to a RuO2-supported catalyst using TiO2 as a support; and a preparation method therefor. According to an embodiment of the present invention, provided is a hydrogen chloride oxidation reaction catalyst to be used in a method for preparing chlorine by oxidizing hydrogen chloride, the catalyst comprising a support and a hetero-material in an active ingredient. The catalyst according to the present invention has both increased catalytic activity at a low temperature and enhanced thermal stability, and thus a catalyst having improved durability such as thermal stability at a high temperature is provided. Therefore, since thermal stability is ensured, the performance of the catalyst is maintained for a long time even at a high temperature.

Owner:HANWHA SOLUTIONS CORP

Catalyst for electrochemical reduction of oxygen

ActiveUS20080202923A1Promotes the instantaneous metathesis of the metal ions and the thionic partInhibition formationActive material electrodesEnergy inputThio-Single crystal

The invention relates to a sulphide catalyst for electrochemical reduction of oxygen particularly stable in chemically aggressive environments such as chlorinated hydrochloric acid. The catalyst of the invention comprises a noble metal sulphide single crystalline phase supported on a conductive carbon essentially free of zerovalent metal and of metal oxide phases, obtainable by reduction of metal precursor salts and thio-precursors with a borohydride or other strong reducing agent.

Owner:IND DE NORA SPA

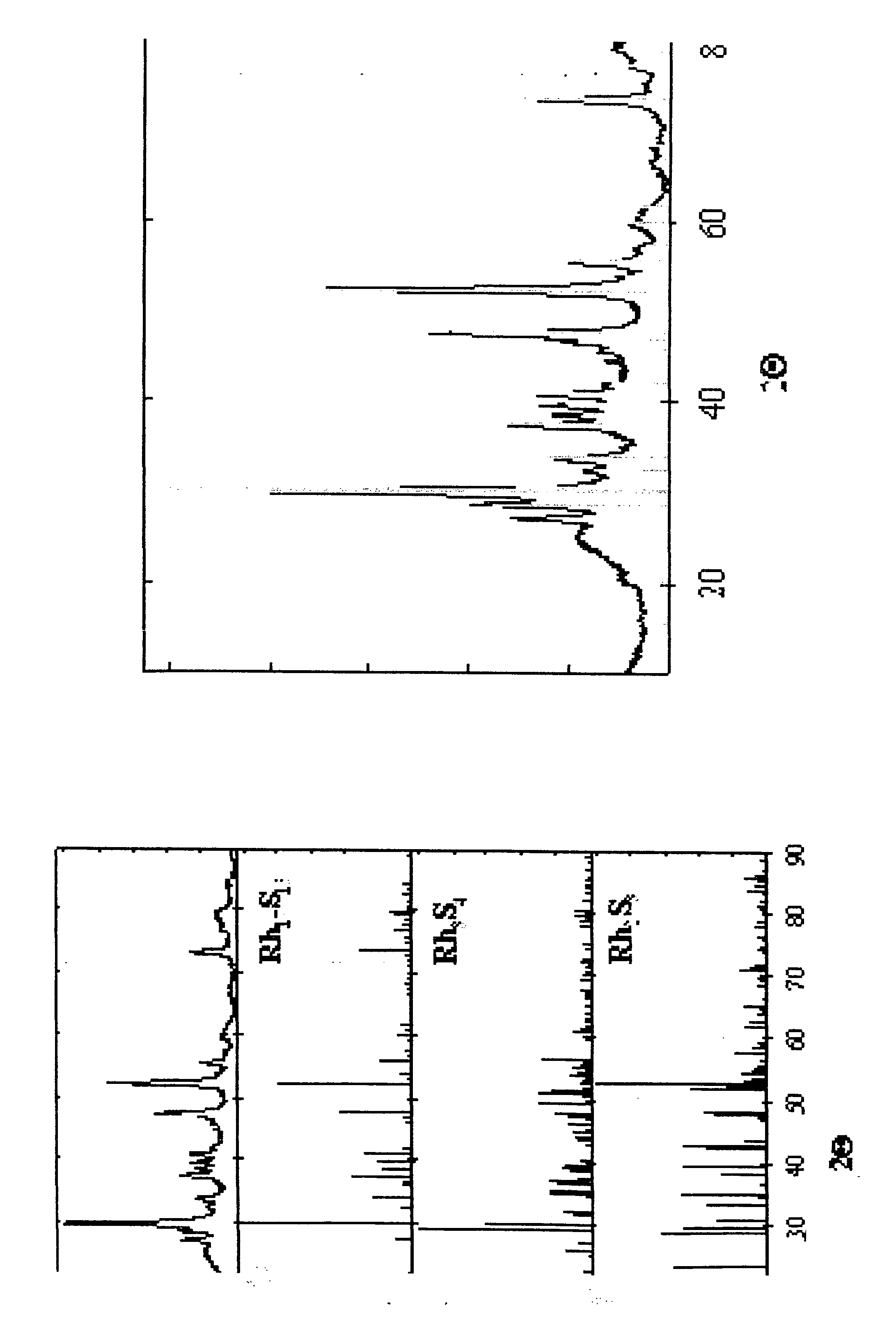

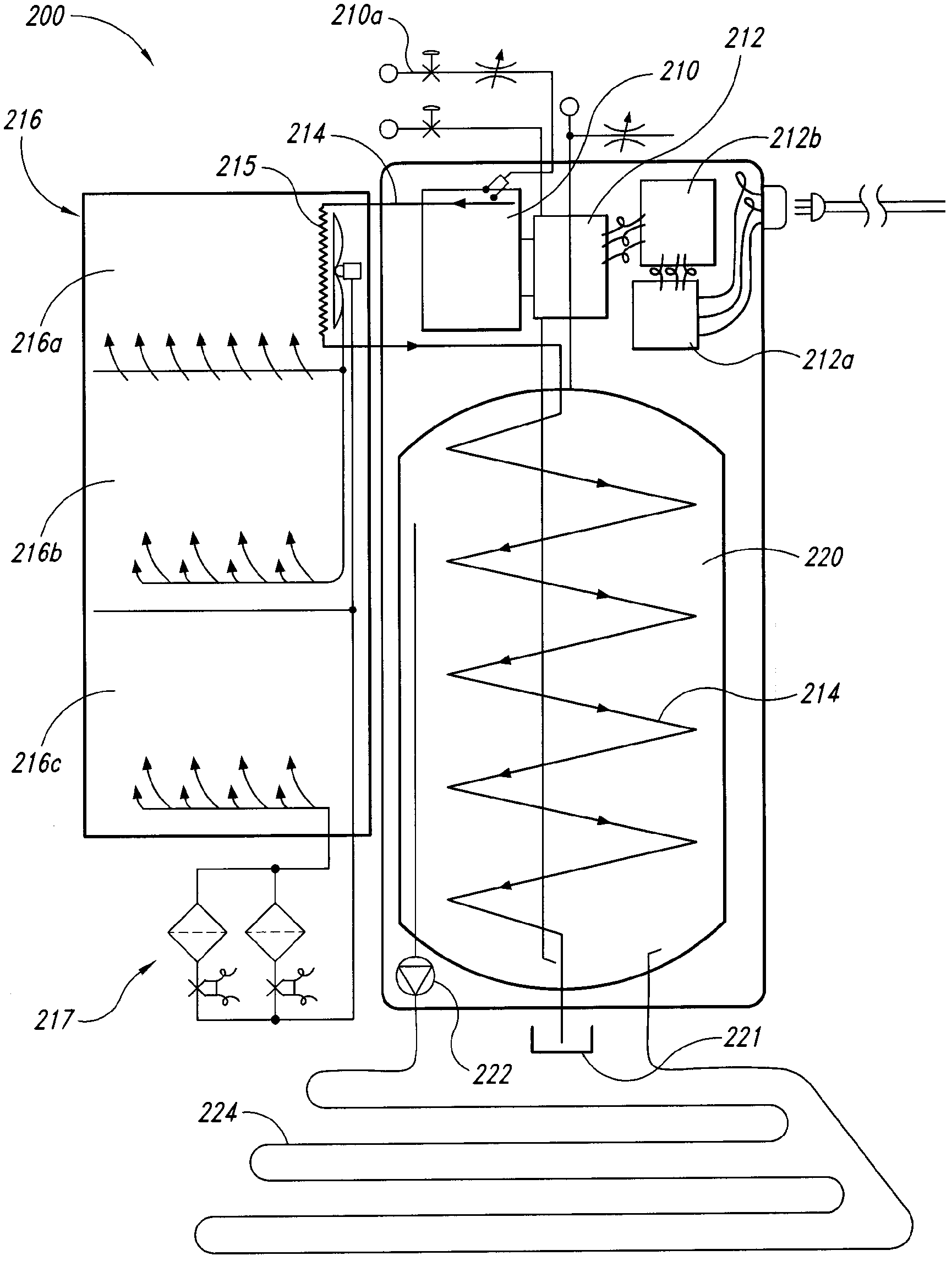

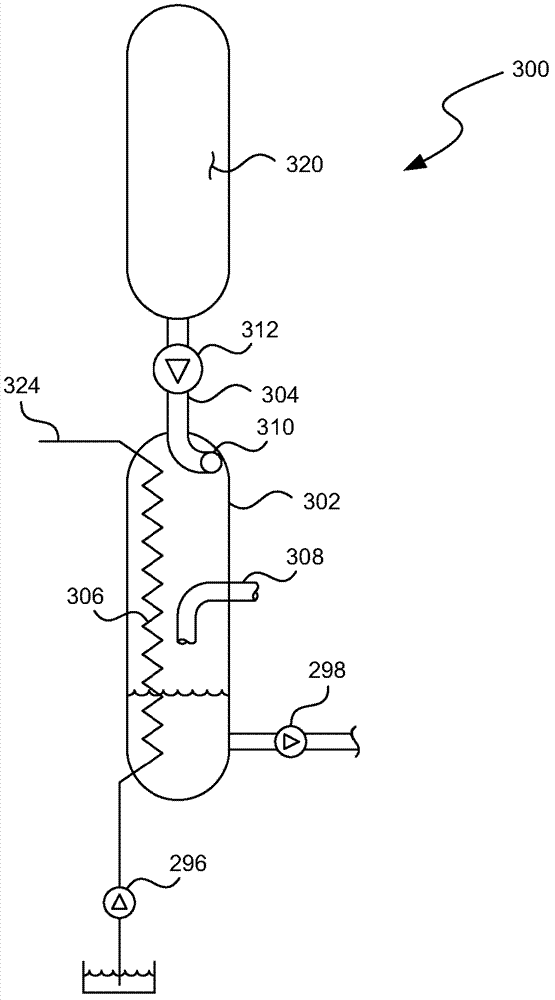

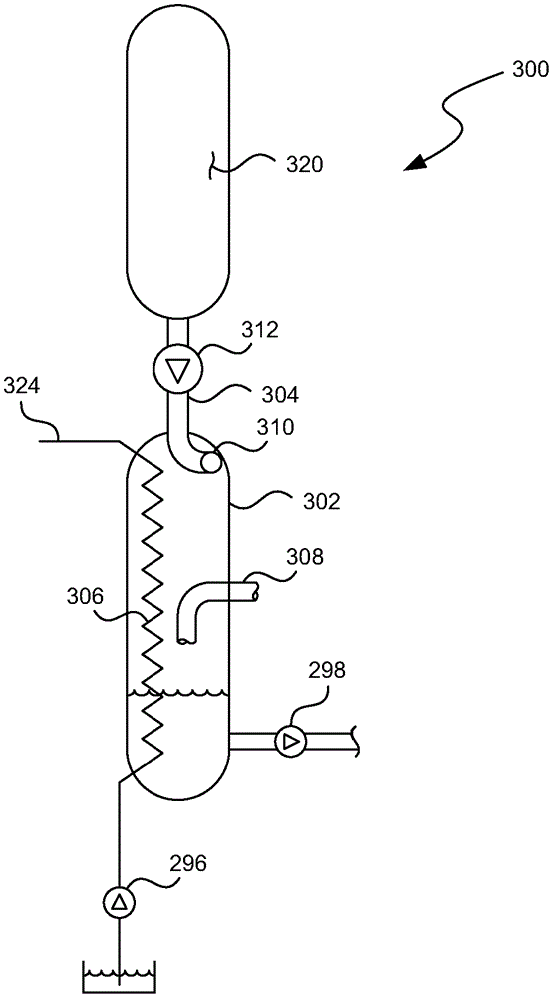

Energy system for dwelling support

The present disclosure is directed to a system and method of providing energy to a dwelling. An engine is housed within an inner tank, which is in turn housed within an outer tank. The engine provides electricity which is used for a dwelling. Exhaust fumes from the engine are piped through a series of heat- exchanging tubes within the outer tank to heat potable water within the outer tank. Water enters the potable tank at a bottom of the tank, and warms as it rises through the outer tank toward an outlet near a top of the outer tank. Hot, potable water is provided from the top of the outer tank to the dwelling. Condensate from the exhaust is captured and used as potable water. Heat, vibration, and acoustic energy from the engine is captured by the fluid in the inner tank and transferred to the outer tank.

Owner:MCALISTER TECH LLC

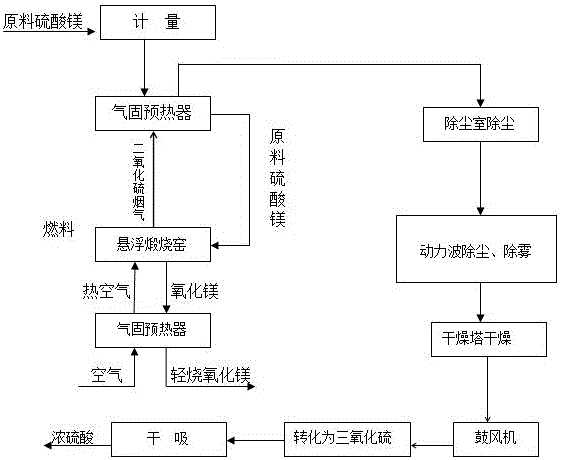

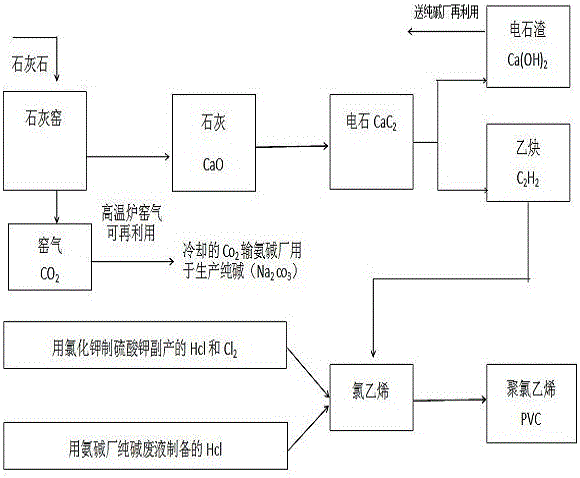

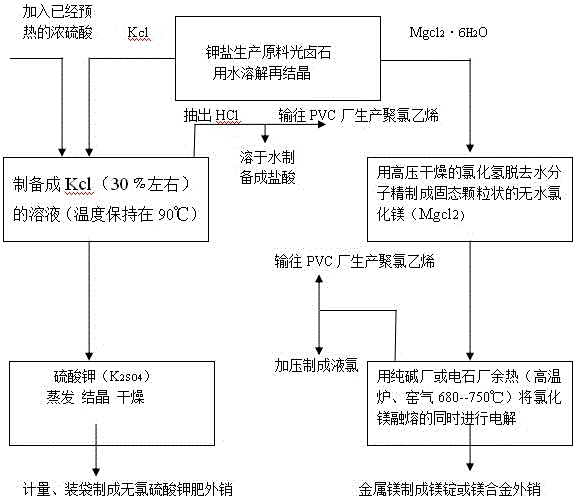

Method for producing potassium sulphate fertilizer magnesium metal PVC and liquid chlorine hydrochloric acid through carnallite

InactiveCN106083221AEmission reductionSave resourcesChlorine/hydrogen-chlorideElectrolysis componentsChemical reactionElectrolysis

The invention discloses a method for producing potassium sulphate fertilizer magnesium metal PVC and liquid chlorine hydrochloric acid through carnallite. According to the technical route, firstly, the carnallite is dissolved with water and then is crystallized, potassium chloride and magnesium chloride hexahydrate contained in the carnallite are separated and purified; then, the magnesium chloride hexahydrate is electrolyzed through the improved Norsk Hydro process to prepare magnesium metal and chlorine; thirdly, a potassium chloride solution and concentrated sulfuric acid are subjected to a chemical reaction under a heated condition to prepare potassium sulfate fertilizer and hydrogen chloride; finally, secondary products including chloride and hydrogen chloride are used for producing liquid chlorine PVC or hydrochloric acid; the sylvite production raw material carnallite can be comprehensively utilized fully. A method for producing sulfuric acid sodium carbonate through natural sulfate (magnesium sulfate and mirabilite) in sylvite residues, a solvay process for producing sodium carbonate and a calcium carbide method for producing PVC are commonly applied, a plant is reasonably planned and established beside a salt lake, scientific cooperative production is achieved, resources can be comprehensively and circularly utilized, energy is saved, emission is reduced, consumption is reduced, and the environment protection is achieved.

Owner:古舜起

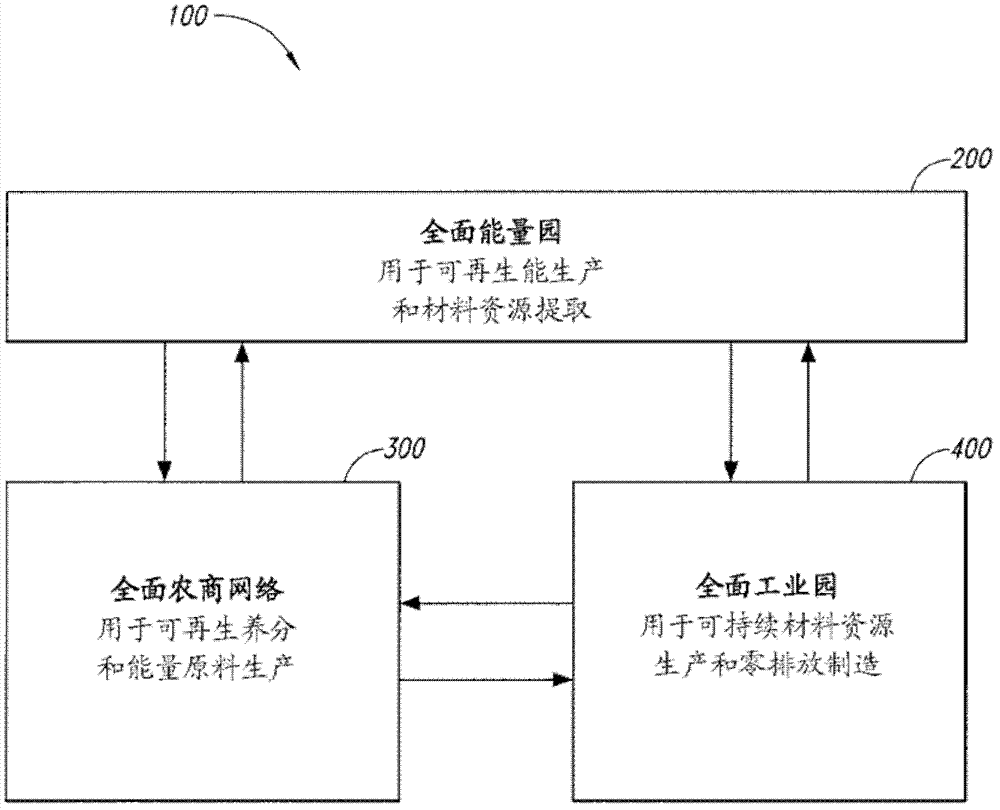

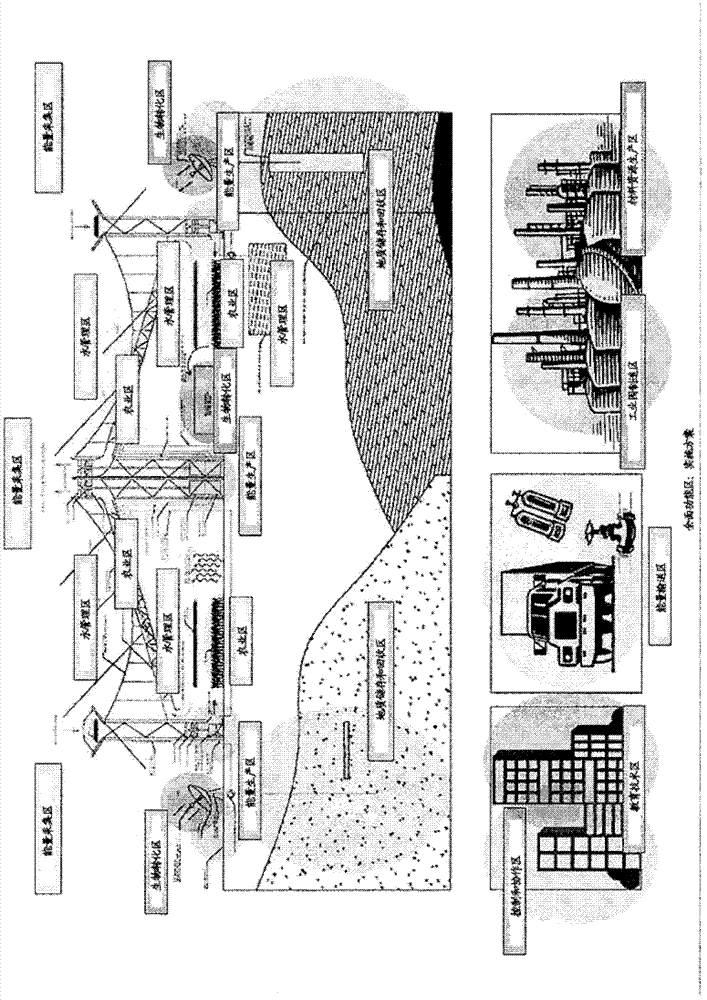

Systems and methods for sustainable economic development through integrated full spectrum production of renewable material resources using solar thermal

InactiveCN102712020ASolar heating energyInternal combustion piston enginesElectrolysisProviding material

In one embodiment of the present invention, a system for providing a renewable source of material resources is provided comprising: a first source of renewable energy; first stream of materials from a first materials source; an electrolyzer coupled to the first source of renewable energy and the first stream of materials, wherein the electrolyzer is configured to produce a first material resource by electrolysis; a processor for further processing or use or the material resource to produce a second material resource, wherein the processor comprises a solar collector and where the solar collector is configured to provide heat to the first materials resource for disassociation; and a material resource storage coupled to the electrolyzer for receiving the material resource from the electrolyzer or providing the material resource to the processor for further processing or use.

Owner:MCALISTER TECH LLC

Regenerative adsorption processes for removing organic components from gas streams

InactiveUS7749307B2Reduce usageGood energySolidificationLiquefactionPhysical chemistryComponents of crude oil

Process for providing a purified gas stream, comprising: providing a crude gas stream comprising an organic impurity; condensing at least a portion of the impurity from the gas stream to form a prepurified gas stream; and subjecting the prepurified stream to adsorption on a first adsorption medium; wherein the first medium is subjected to a regeneration comprising: providing a circulating inert gas stream having a temperature of at least 100° C.; passing the circulating inert gas stream over the first medium to form an organic impurity-loaded inert gas stream; cooling the loaded stream; condensing at least a portion of the organic impurity from the cooled stream to provide a prepurified circulating inert gas stream; subjecting the prepurified gas stream to adsorption on a second adsorption medium to provide a purified circulating inert gas stream; and recycling the purified gas stream to the circulating inert gas stream.

Owner:BAYER MATERIALSCIENCE AG

Systems and methods for sustainable economic development through integrated full spectrum production of renewable energy

In one embodiment of the present invention, a method for providing an energy supply using a renewable energy source is provided comprising: providing a first source of renewable energy, wherein the first source of renewable energy is intermittent or does not provide a sufficient amount of energy; providing energy from the first source of renewable energy to an electrolyzer to produce an energy carrier through electrolysis; selectably reversing the electrolyzer for use as a fuel cell; and providing the energy carrier to the electrolyzer for the production of energy.

Owner:MCALISTER TECH LLC

Systems and methods for sustainable economic development through integrated full spectrum production of renewable material resources using solar thermal

InactiveCN102712020BSolar heating energyInternal combustion piston enginesElectrolysisCrystal structure

In one embodiment of the invention there is provided a system for providing a renewable source of material resources, the system comprising: a first source of renewable energy; a first material stream from the first material source; and an electrolyzer connected to the first source of renewable energy and the first material stream, wherein the electrolyzer is configured to produce a first material resource by electrolysis; a processor for further processing or using the said material resource to produce a second material resource, wherein said processor includes a solar collector and wherein said solar collector is configured to provide heat to said first material resource for dissociation; and a material resource reservoir, said A material resource storage is coupled to the electrolyzer to receive material resources from the electrolyzer or provide material resources to the processor for further processing or use.

Owner:MCALISTER TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com