Method and system for recovering products from steel slag

A technology for recycling products and slag, applied in chemical instruments and methods, wet separation, chlorine production, etc., to achieve improved utilization, enhanced conversion kinetics and conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

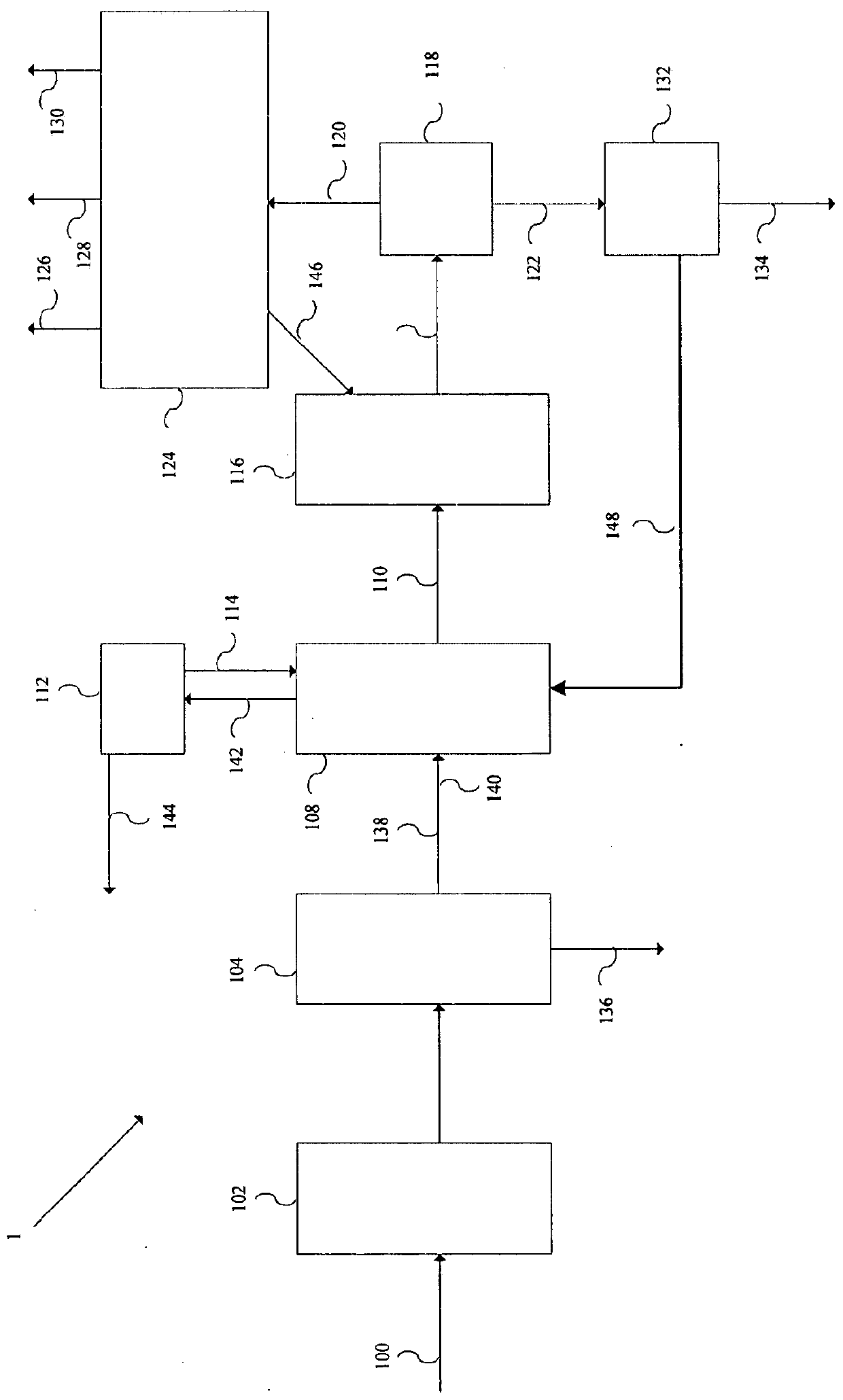

[0035] now refer to figure 1 , in some embodiments, the present disclosure relates to a system 1 for producing various products from steel slag. In some embodiments, a first source 100 of steel or iron slag is collected. In some embodiments, first source 100 is fed to grinding module 102 . In some embodiments, the first source 100 is fed to a magnetic separator 104 . In some embodiments, the separated fraction from the magnetic separator is fed to the slag processing module 108 . The slag processing module 108 produces a slurry 110 .

[0036] In some embodiments, the first precipitation module 112 communicates with the slag handling module 108 via at least a first recycle stream 114 .

[0037] In some embodiments, the slurry 110 is fed to an acid leach module 116, which produces dissolved leachate and slag residue. In some embodiments, separator 118 separates dissolved leachate and slag residue to produce at least one dissolved leachate stream 120 and slag residue product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com