Synchronous production process for manganese metal and chlorine disinfectant through electrolytic cell

A production process and electrolytic cell technology, applied in the field of synchronous production process, can solve the problems of hovering around 75% and high DC power consumption, and achieve the effect of reducing energy consumption and improving energy utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The solution of the present invention will be further described in detail below with reference to the examples, but this description will not constitute a limitation to the present invention.

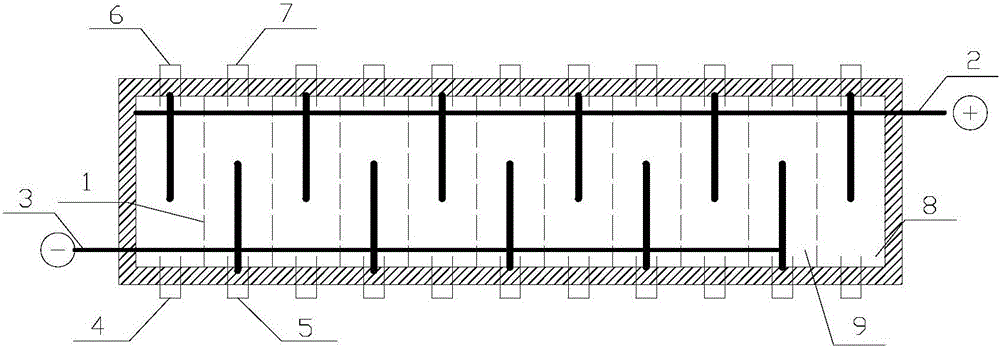

[0019] The simultaneous production process of metal manganese and chlorine disinfectant is carried out by using an electrolytic cell, and the constant current electrolysis technology can be used to realize the simultaneous production of depositing metal manganese and generating chlorine disinfectant. The electrolytic cell includes a single unit electrolytic cell, and An anion exchange membrane 1 and a sealing gasket are arranged between the unit electrolyzers; wherein, the anion exchange membrane is a polyfluorovinyl or polysulfone-based homogeneous anion exchange membrane with high conductivity; the inner end of the unit electrolyzer The mesh anode 2 and the plate cathode 3 are alternately arranged, which are called the anode chamber 8 and the cathode chamber 9, respectively. The me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com