Method for producing potassium sulphate fertilizer magnesium metal PVC and liquid chlorine hydrochloric acid through carnallite

A carnallite, metal magnesium technology, applied in chemical instruments and methods, potash fertilizer, chlorine production, etc., to save resources, protect the environment, achieve zero emissions, and reduce waste and exhaust emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

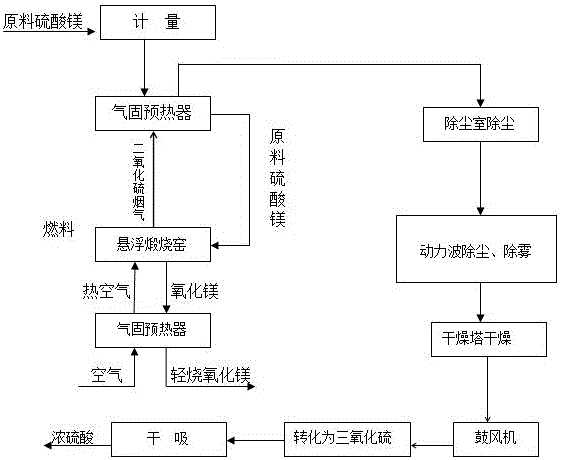

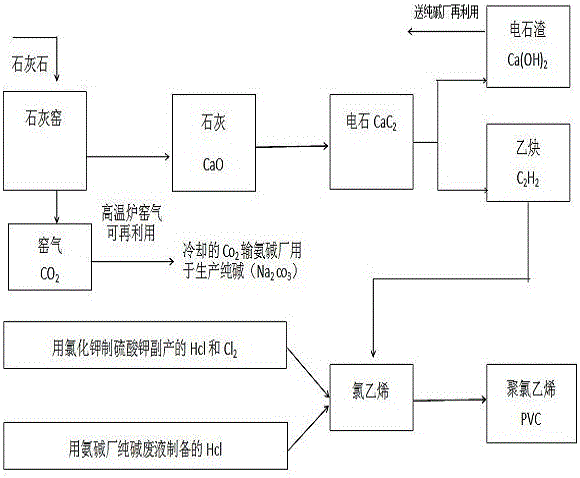

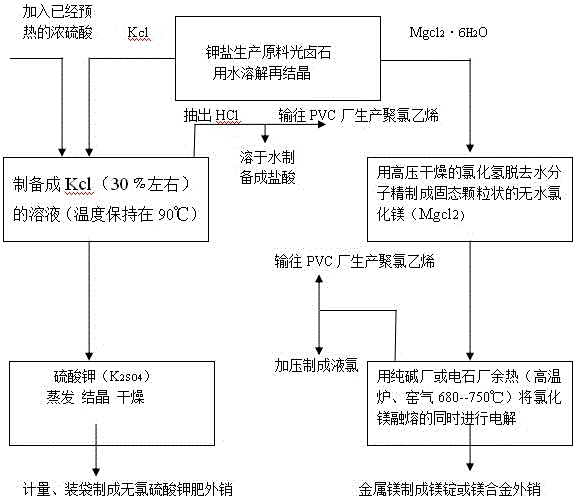

[0011] The present invention is related to the "method for comprehensive utilization of natural magnesium sulfate in potassium salt residue to squeeze out and use up" (separate patent application), "method for producing soda ash by using mirabilite in potassium salt residue", "ammonia for producing soda ash" Alkali method" and "calcium carbide method for PVC production" are used together, and the plant is reasonably planned and built next to the potash enterprise near the salt lake like the pit mouth power generation. Each factory scientifically utilizes magnesium chloride, magnesium sulfate, sodium sulfate, sodium chloride, calcium chloride and other resources in the potash residue (accurately speaking, the residue of carnallite, which is the raw material for potash) Routes and processes for the production of sulfuric acid, soda ash, chlorine-free potassium sulfate fertilizer, PVC, metal magnesium, hydrochloric acid, and liquid chlorine, and finally, comprehensive utilization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com