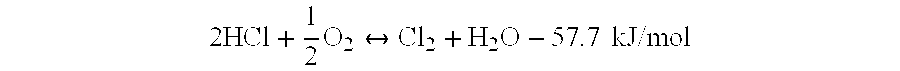

Catalyst for preparing chlorine by oxidation of hydrogen chloride and preparation thereof

a hydrogen chloride and catalyst technology, applied in the direction of chloride preparation, physical/chemical process catalysts, metal/metal-oxide/metal-hydroxide catalysts, etc., can solve the problem of low added value of produced hydrochloric acid, difficult to find hydrogen chloride outlets, and oversupply of sodium hydroxide, etc. problems, to achieve the effect of improving stability, reducing price and being easy to prepar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0035]In a 40 ml of aqueous solution that contains 26.3 g CuCl2.2H2O, 60 g of HY molecular sieve (rare earth HY molecular sieve, manufactured by Mingmeiyoujie Mining Co. Ltd., Mingguang City, the same below) is impregnated for 12 h, then dried at 90° C. for 16 h. The resultant solid is re-dispersed in a 50 ml of aqueous solution that contains 0.92 g H3BO3, 4.95 g KCl, 8.15 g Ce(NO3)3.6H2O and 4.05 g Nd(NO3)3.6H2O to perform impregnation for 12 h, then dried at 90° C. for 16 h. The dried solid is calcined at 500° C. for 4 h to obtain 90 g of active catalyst. It is tableted to obtain catalyst granules of 30-60 mesh. 6 g of the catalyst of 30-60 mesh is loaded in a fixed bed reactor to conduct a reaction with of the flow rates of hydrogen chloride and oxygen of 100 ml / min respectively, with the reaction temperature at 380° C. and the reaction pressure at 0.18 MPa. After 4 h of reaction, the chlorine yield is 88.6%; and after 100 h of reaction, the chlorine yield is 89.0%. The activity ...

example 2

[0039]In a 41 ml of aqueous solution that contains 26.3 g CuCl2.2H2O, 60 g kaolin is impregnated for 12 h, then dried at 90° C. for 16 h. The resultant solid is re-dispersed in a 49 ml of aqueous solution that contains 1.15 g H3BO3, 4.95 g KCl, 8.15 g Ce(NO3)3.6H2O and 4.05 g La(NO3)3.6H2O to perform impregnation for 12 h, then dried at 90° C. for 16 h. After being calcined at 500° C. for 4 h, 90 g of active catalyst is obtained. It is tableted to obtain catalyst granules of 30-60 mesh. With the same reaction conditions as in Example 1, the chlorine yield is 86.1% after 4 h of reaction and is 85.8% after 100 h of reaction. The activity of the catalyst substantially remains unchanged. After 1000 h of reaction, the catalyst still keeps its activity with the chlorine yield of 85.4%.

example 3

[0040]In a 45 ml of aqueous solution that contains 17.8 g CuCl2.2H2O and 11.5 g Co(NO3)2.6H2O, 60 g HY molecular sieve is impregnated for 12 h, then dried at 90° C. for 16 h. The resultant solid is re-dispersed in a 50 ml of aqueous solution that contains 0.46 g H3BO3, 4.95 g KCl, 8.15 g Ce(NO3)3.6H2O and 4.05 g Pr(NO3)3.6H2O to perform impregnation for 12 h, then dried at 90° C. for 16 h. After being calcined at 500° C. for 4 h, 86 g of active catalyst is obtained. It is tableted to obtain catalyst granules of 30-60 mesh. With the same reaction conditions as in Example 1, the chlorine yield is 86.4% after 4 h of reaction and is 86.8% after 100 h of reaction. The catalyst keeps a stable activity. The chlorine yield is 86.0% after 1000 h of reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com