Method of making high purity lithium hydroxide and hydrochloric acid

A technology of lithium hydroxide and lithium hydroxide monohydrate, which is applied in the direction of lithium oxide;/hydroxide, hydrogen chloride preparation, chloride preparation, etc., can solve the problems of not providing lithium products, difficult separation cost, expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

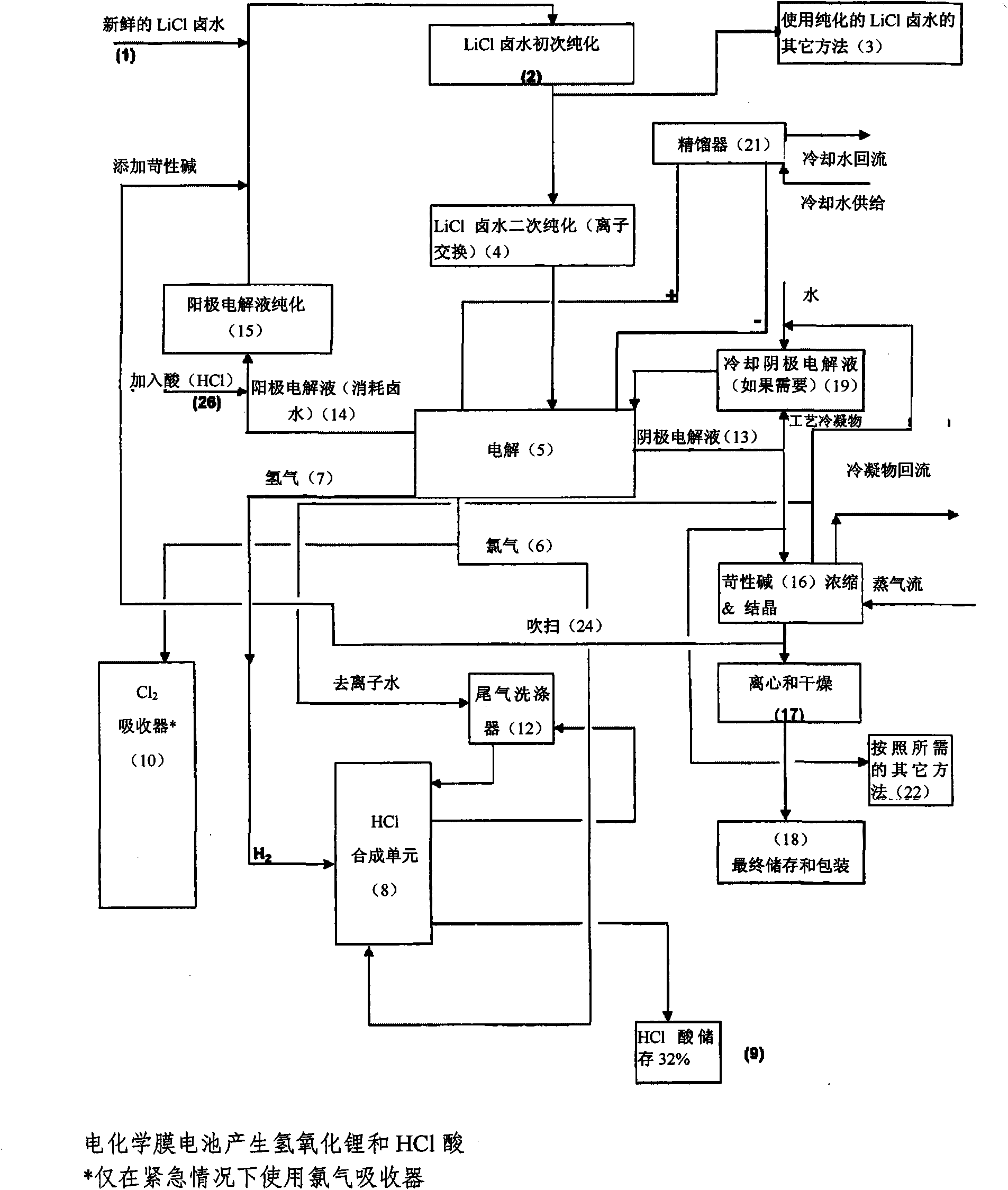

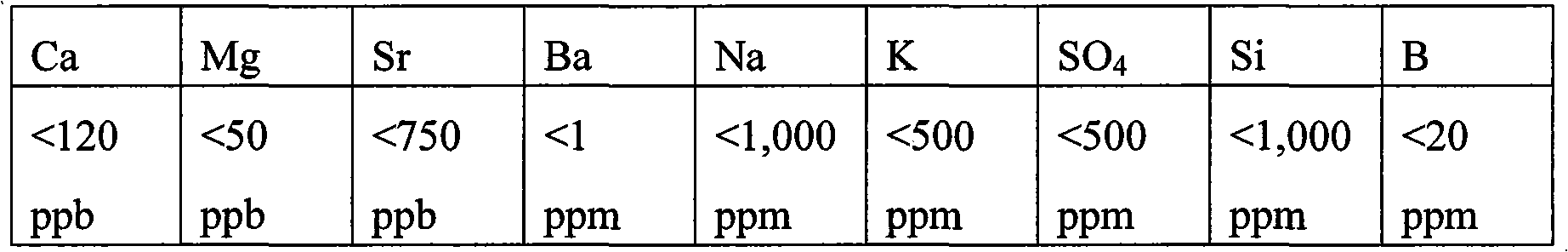

[0107] Referring to the accompanying drawings, which disclose the process of a preferred embodiment of the invention, a lithium chloride-containing brine (1) is provided, which may be natural or produced eg from ores. The brine is subjected to an initial purification step (2) to reduce the content of unwanted ions or other impurities. This can be accomplished by, for example, precipitating magnesium, boron, barium and calcium or sodium, forming insoluble salts by methods such as those previously described or other methods known in the art, adjusting the pH of the brine to make it alkaline so that unwanted ions form hydroxides precipitation. This brine is then used in further steps, using brine (3) or more suitable for the application at hand, for a secondary purification step (4) using ion exchange such as described above. Finally, the total amount of Ca and Mg in the brine before electrolysis is lower than 150 ppb by any combination of chemical, solar evaporation, or ion exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com