Heat exchange type reactor

一种反应器、放热反应的技术,应用在间接换热器、换热器类型、化学/物理/物理化学固定式反应器等方向,能够解决显热带出量和散热量超过、不能维持反应温度、反应收获率降低等问题,达到抑制反应收获率的降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

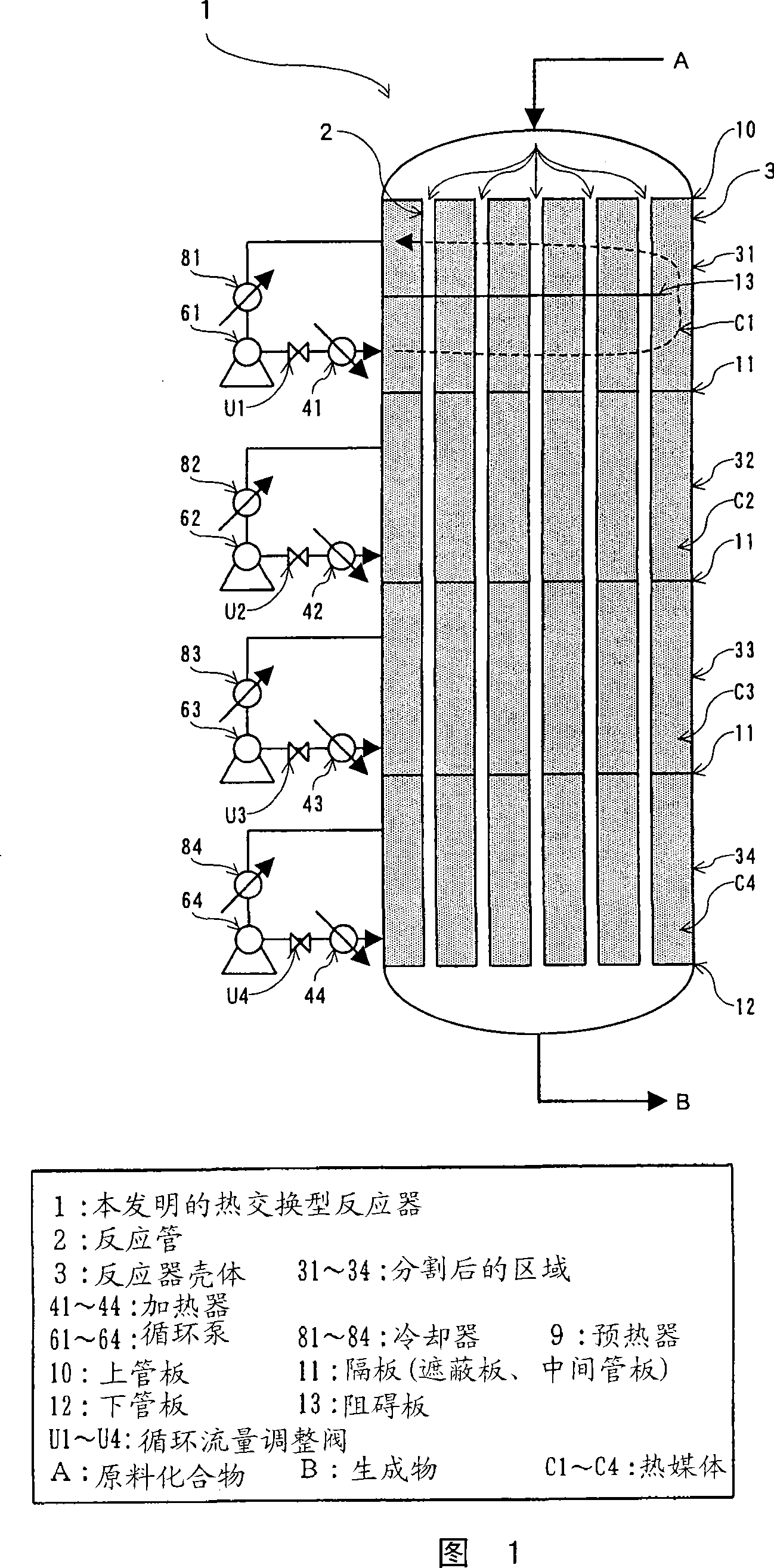

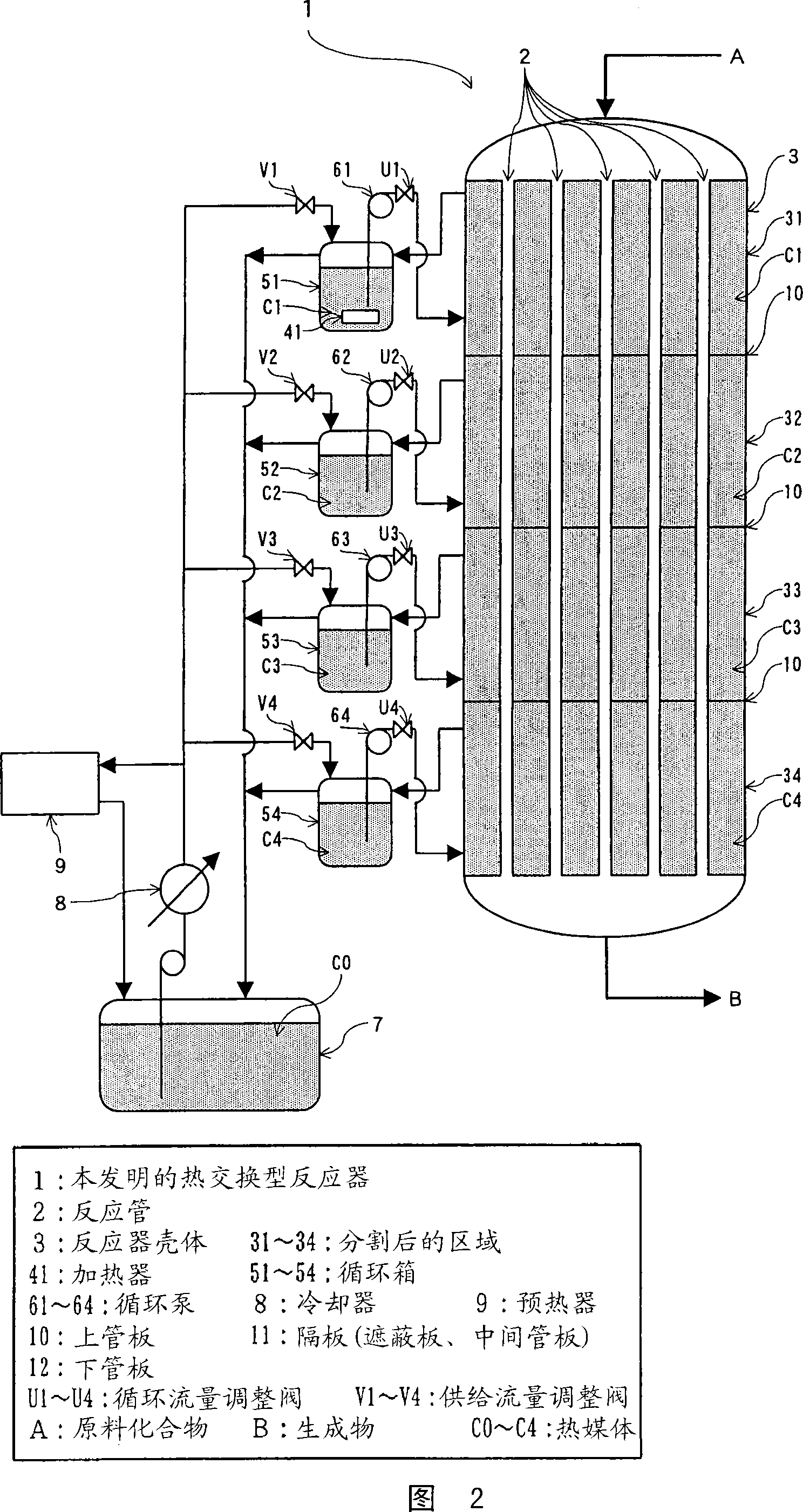

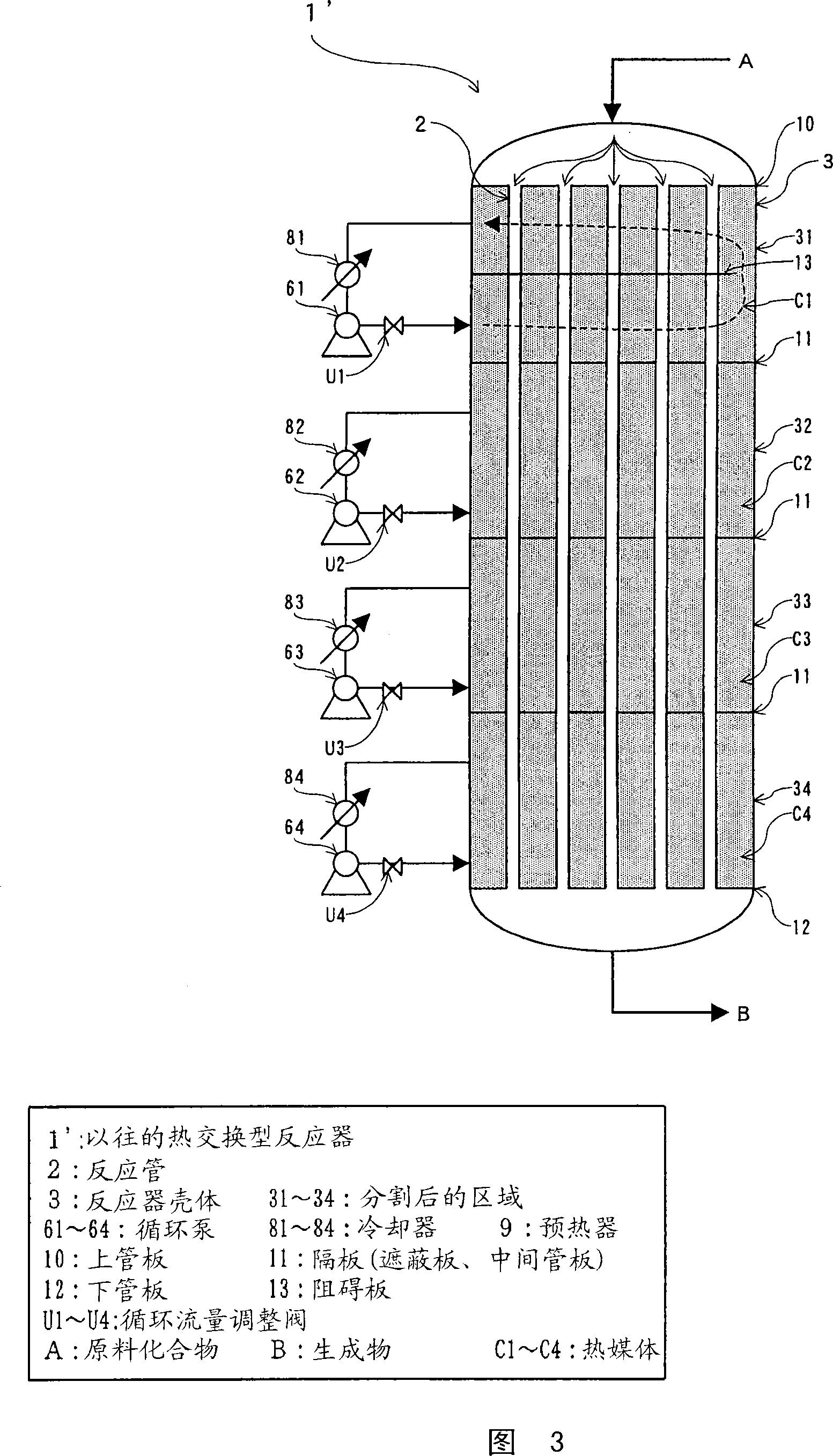

[0024] The raw material compound (A) used in the heat exchange reactor (1) of the present invention is a compound that becomes a product (B) through an exothermic reaction, and a gaseous compound is usually used. Specifically, for example, for obtaining chlorine (Cl 2 ) of hydrogen chloride (HCl) and oxygen (O 2 ), propylene and oxygen (O 2 ), is used to obtain methacrolein and isobutene and oxygen (O 2 )Wait.

[0025] The raw material compound (A) may be used without dilution, or may be used by diluting with an inert substance that is not reactive. If the raw material compound (A) is used without dilution, it is not necessary to separate the inert gas used for dilution from the product (B), which is preferable. In addition, when used without dilution, generally, the predetermined reaction temperature is easily exceeded in a region with a large amount of heat generation, and is easily lower than a predetermined reaction temperature in a region with a small heat generation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com