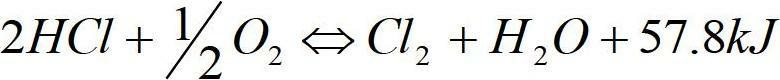

Copper oxide catalyst for preparing chlorine gas from chlorine hydride by catalytic oxidation, and preparation method and application thereof

A technology for catalytic oxidation and hydrogen chloride, applied in the direction of metal/metal oxide/metal hydroxide catalyst, preparation with chloride, catalyst activation/preparation, etc., can solve problems such as increased catalyst viscosity, high cost of ruthenium compounds, and equipment corrosion , to improve the activity and stability, the preparation method is simple and easy, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the activated alumina modified by rare earth oxide comprises the following steps:

[0033] Aluminum nitrate and cerium nitrate are mixed and dissolved, and ammonia water is added to the mixed solution under stirring until the pH is 8.6 to obtain alumina gel;

[0034] The weight percent content of cerium nitrate is 3.40% of the total weight of aluminum nitrate and cerium nitrate;

[0035] After washing and filtering the obtained gel, dry it at 90°C for 12 hours, then pretreat it in a tube furnace at 500°C for 4 hours, and finally calcinate the obtained product at 1100°C for 24 hours to prepare ceria-modified activated alumina , the weight percent content of cerium oxide is 8.7%;

[0036] 14.25gCuCl 2 2H 2 O and 3.75g KCl were dissolved in 31.5mL of deionized water, and then an equal volume of 57.5g of ceria-modified activated alumina support was impregnated, and finally stirred at 60°C for 2h, kept at 40°C for 12h, and dried at 120°C for 12h ,...

Embodiment 2

[0044] Carrier: the preparation method of activated alumina modified by rare earth oxide, comprising the following steps:

[0045] Aluminum nitrate and lanthanum nitrate are mixed and dissolved, and ammonia water is added to the mixed solution until the pH is 8.6 under stirring to obtain an alumina gel;

[0046] The weight percent content of lanthanum nitrate is 3.38% of the total weight of aluminum nitrate and lanthanum nitrate;

[0047] After washing and filtering the obtained gel, dry it at 90°C for 12h, then pretreat it in a tube furnace at 500°C for 4h, and finally calcinate the obtained product at 1100°C for 24h to obtain a rare earth oxide-modified active Aluminum oxide; Lanthanum oxide weight percent content is 8.7%;

[0048] 14.25gCuCl 2 2H 2 O and 3.75g KCl were dissolved in 31.5mL deionized water, and then 57.5g of lanthanum oxide-modified activated alumina carrier () was impregnated with an equal volume, and finally stirred at 60°C for 2h, kept at 40°C for 12h, ...

Embodiment 3

[0055] Aluminum nitrate and lanthanum nitrate are mixed and dissolved, and ammonia water is added to the mixed solution until the pH is 8.6 under stirring to obtain an alumina gel;

[0056] The weight percentage content of lanthanum nitrate is 2.6% of aluminum nitrate and lanthanum nitrate gross weight;

[0057] After washing and filtering the obtained gel, dry it at 90°C for 12h, then pretreat it in a tube furnace at 500°C for 4h, and finally calcinate the obtained product at 1100°C for 24h to obtain a rare earth oxide-modified active Aluminum oxide; Lanthanum oxide weight percent content is 6.9%;

[0058] 11.88gCuCl 2 2H 2 O and 3.12g KCl were dissolved in 33.8mL of deionized water, and then 60.4g of lanthanum oxide-modified activated alumina carrier was impregnated with equal volume, and finally stirred at 60°C for 2h, kept at 40°C for 12h, and dried at 120°C for 12h , Calcined at 400°C for 4h in an air atmosphere to prepare a supported copper oxide catalyst.

[0059] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com