Hydrolysis method for material containing hydrolysable halogen atom

A technology of halogen atoms and substances, which is applied in the field of producing solid oxides and hydrogen halide products, can solve problems such as high operating costs, complex equipment, and difficult continuous reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

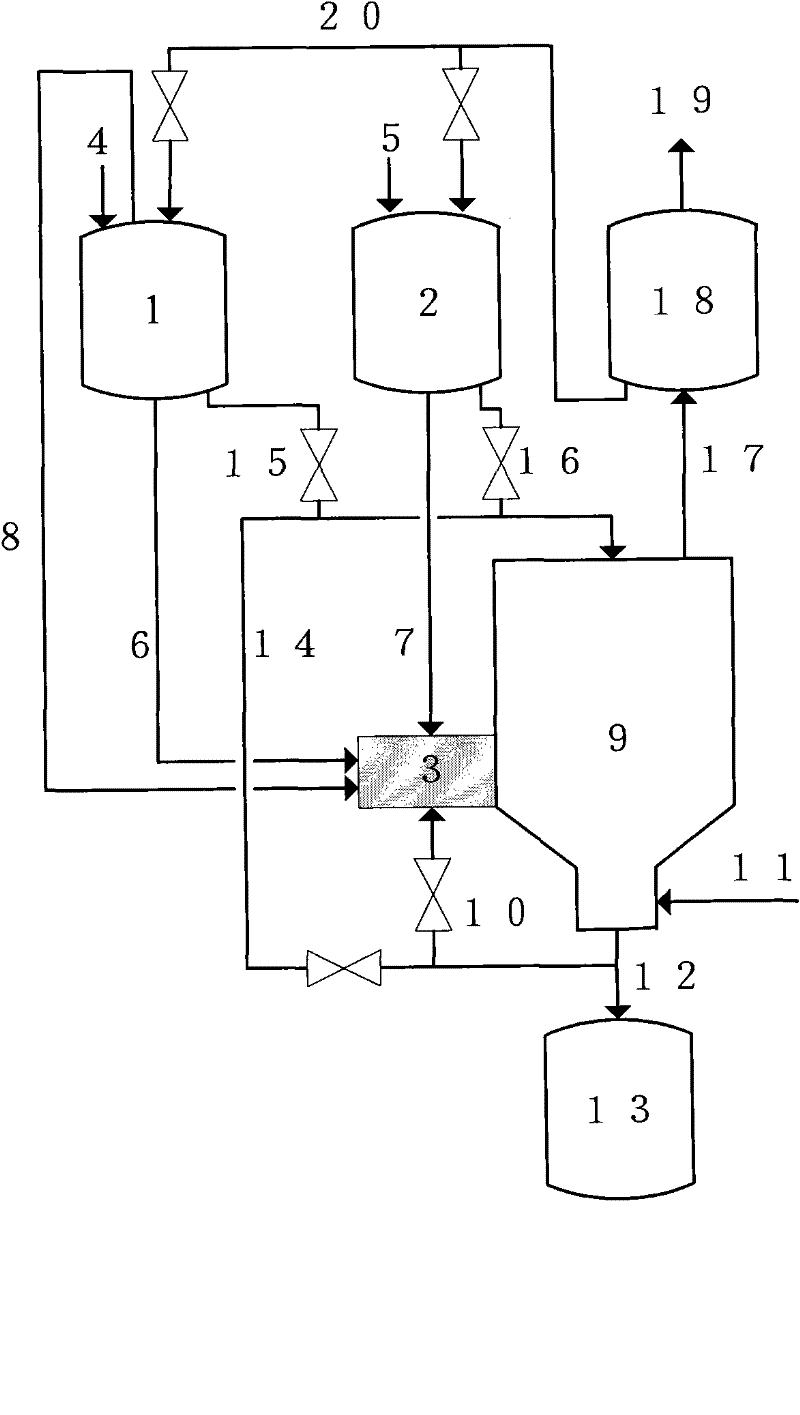

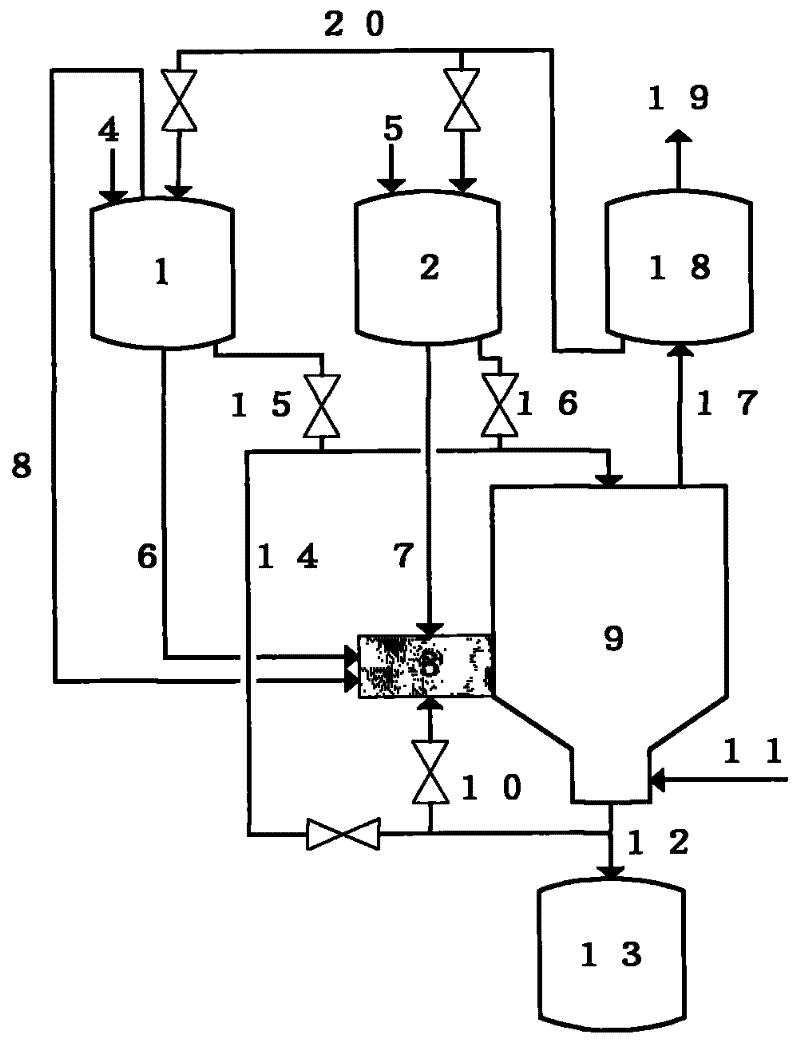

[0050] According to the flow process in the accompanying drawings of the present invention, but there is no solid material circulation part of 10 in the accompanying drawings, the gas purification part of 14, 15 and 16 in the accompanying drawings and the inert gas stripping part of 11 in the accompanying drawings. The mixing part of the reaction and mixing unit 3 is a static mixer, the reaction part is a screw conveyor, and the gas purification unit 18 is composed of a cyclone separator and a condensing device (three-stage condensation is used, first cooled with water, and then cooled to -20 with frozen brine. ℃, and finally use a refrigerant (R507 or R404 can be used) to freeze to -40 ℃, and more than 99% of silicon tetrachloride can be condensed).

[0051] The substance containing hydrolyzable halogen atoms mentioned in this implementation experiment is silicon tetrachloride, and its purity is 99.4%.

[0052] Before the start of the experiment, the stirring of the gas-solid...

Embodiment approach 2

[0056] This implementation experiment follows the process flow in the accompanying drawings, but there is no gas purification part of 14, 15 and 16 in the accompanying drawings and the inert gas stripping part of 11 in the accompanying drawings. The reaction gas product from 17 is directly passed into the lower part of the storage tank 2, and the storage tank 2 is used as a bubbling reactor to achieve the purpose of gas product dust removal and residual reactants, that is, the storage tank 2 serves as the gas purification unit 18 at the same time. The reaction and mixing unit 3 is a screw conveyor.

[0057] The material containing hydrolyzable halogen atoms mentioned in this embodiment is the synthesis tail gas of trichlorosilane, and its volume composition is hydrogen 60~70%, hydrogen chloride 25~35%, trichlorosilane 4~6%, other (such as two Chlorine dihydrogen silicon, etc.) 0.1 to 0.6%.

[0058] Before the start of the experiment, the gas-solid separation and purifier 9 we...

Embodiment approach 3

[0061] The flow process of this implementation experiment is the same as that of Example 1, and the difference from Example 1 is that the mixing part of the reaction and mixing unit 3 is a booster Venturi mixer, and the reaction part is an air conveyor.

[0062] The substance containing hydrolyzable halogen atoms mentioned in this implementation experiment is the waste liquid of the raffinate collection tank of the polysilicon production plant. Its composition varies greatly with different sources, usually 1-5% of trichlorosilane, 10-30% of silicon tetrachloride, 40-60% of polychlorosilane, 5-20% of solid impurities such as metal silicon powder, Others (containing titanium tetrachloride, aluminum trichloride, boron trichloride, etc.) 1-5%.

[0063] Before the experiment starts, the gas-solid separation and the stirring of the purifier 9 are turned on. Turn on the condensing unit of 18. After the experiment started, the waste liquid in the storage tank 1 passed through 6 to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com