Vacuum sublimation purifying method of OLED (organic light emitting diode) material

A purification method and vacuum technology, applied in the field of vacuum sublimation purification, can solve the problems of difficult to achieve continuous purification, limited purity, complicated operation of the purification method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

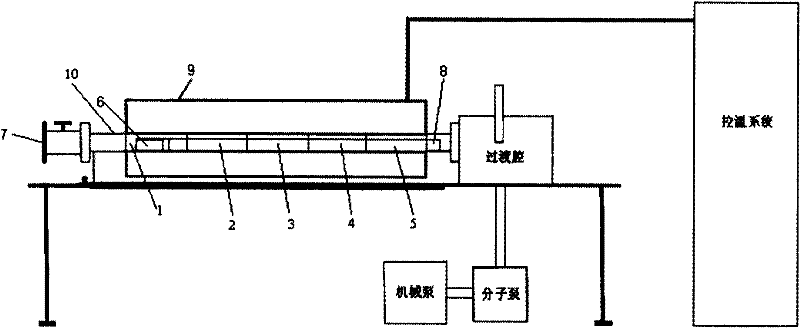

[0046] Taking CBP as an example, the entire vacuum sublimation purification process is figure 2 In the described vacuum sublimation purification equipment, the equipment mainly includes a quartz outer tube 10 that acts as a vacuum isolation and a quartz inner sleeve 8 that acts as a deposition chamber, a heating furnace 9, a temperature control system and a vacuum system. The furnace has five controllable temperature zones: the first sub zone 1, the second sub zone 2, the third sub zone 3, the second zone 4 and the third zone 5. The first temperature zone is composed of the first sub-temperature zone 1 , the second sub-temperature zone 2 and the third sub-temperature zone 3 .

[0047] The vacuum sublimation purification method is as follows: open the vacuum chamber door 7, put 1 g of synthesized and chemically purified CBP (purity of 95%) into the quartz boat 6, and put the quartz boat 6 into the corresponding first sub-temperature zone In the quartz sleeve 8 at position 1, ...

Embodiment 2

[0049] with Alq 3 For example, the entire vacuum sublimation purification process is figure 2 In the described vacuum sublimation purification equipment, the equipment mainly includes a quartz outer tube 10 that acts as a vacuum isolation and a quartz inner sleeve 8 that acts as a deposition chamber, a heating furnace 9, a temperature control system and a vacuum system. The furnace has five controllable temperature zones: the first sub zone 1, the second sub zone 2, the third sub zone 3, the second zone 4 and the third zone 5. The first temperature zone is composed of the first sub-temperature zone 1 , the second sub-temperature zone 2 and the third sub-temperature zone 3 .

[0050] The vacuum sublimation purification method is as follows: open the vacuum chamber door 7, put the chemically purified Alq 3 (Purity is 98%) 0.98g is put into the quartz boat 6, the quartz boat 6 is put into the quartz sleeve 8 corresponding to the position of the first sub-temperature zone 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com