Method for inhibiting formation of coffee ring in printing process and solid thin film

A coffee ring and process technology, applied in the post-processing, printing and other directions of printing, can solve the problems of roughness, loose film layer, unfavorable process and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0036] A specific example is as follows:

[0037] Functional ink composition: by mass ratio, including 0.6% P-PPV and 94.4% solvent, wherein the solvent composition is as follows: chlorobenzene and 3,4-dimethylanisole, and the volume ratio of the two is: chlorobenzene and 3,4-Dimethylanisole=80:20. The preparation process is as follows:

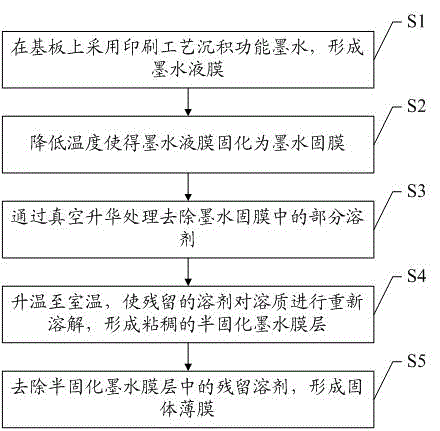

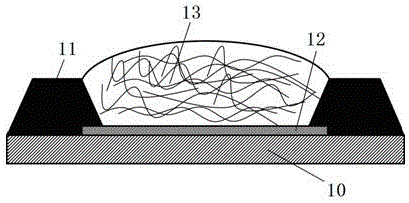

[0038] 1. Use printing process to deposit functional ink in the pixel pit of the substrate to form ink liquid film;

[0039] 2. Lower the temperature to -50°C (the melting point of chlorobenzene is -45°C) to solidify the ink liquid film and form a solid ink film;

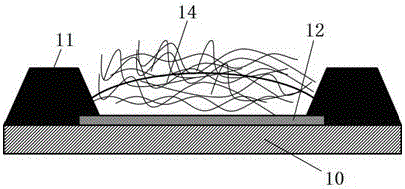

[0040] 3. Put the cured ink solid film under vacuum, the vacuum degree is 10Pa, sublimation removes 70% (by volume) of chlorobenzene;

[0041] 4. Return the ink solid film to room temperature to form a semi-cured ink film layer;

[0042] 5. Vacuum the semi-cured ink film layer to remove the remaining solvent and form a dense solid film.

[0043] In summary, the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com