Preparation method of 2,2-bis(3-amino-4-hydroxylphenyl)hexafluoropropane

A technology of hydroxyphenyl and hexafluoropropane, which is applied in 2 fields, can solve the problems of low yield, harsh reaction conditions, and quality that meets electronic grade requirements, and achieves the effect of low boiling point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

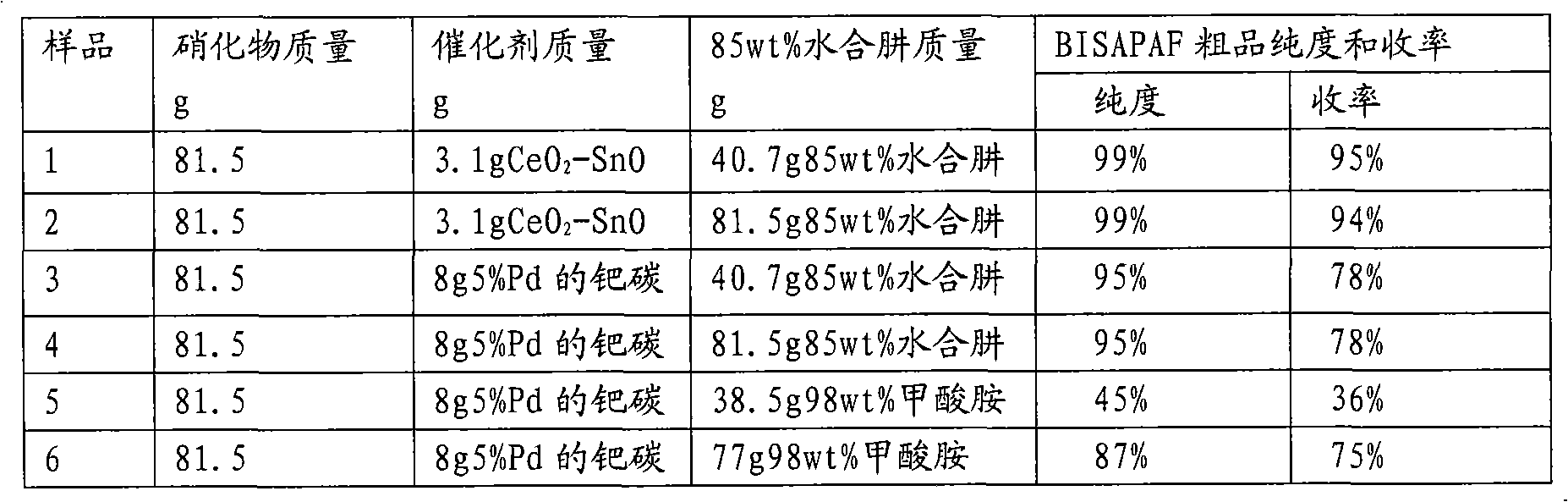

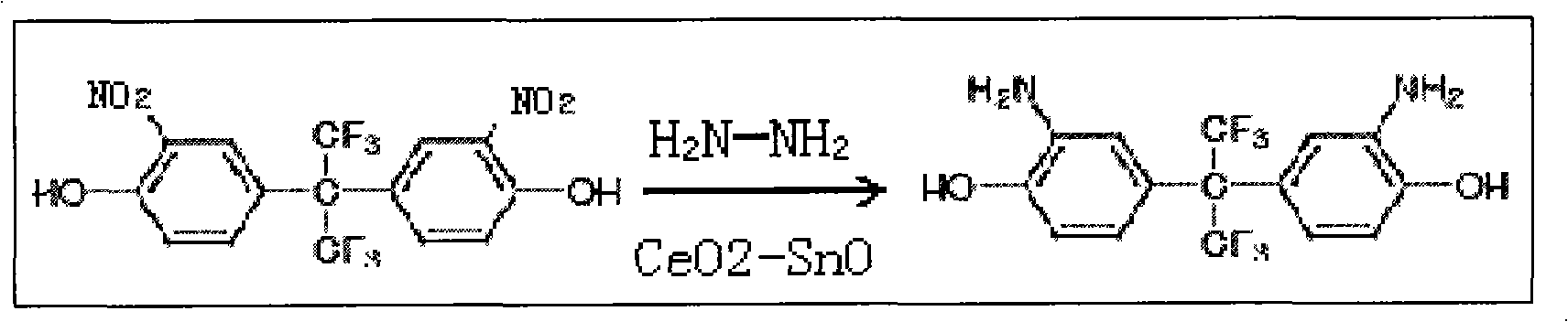

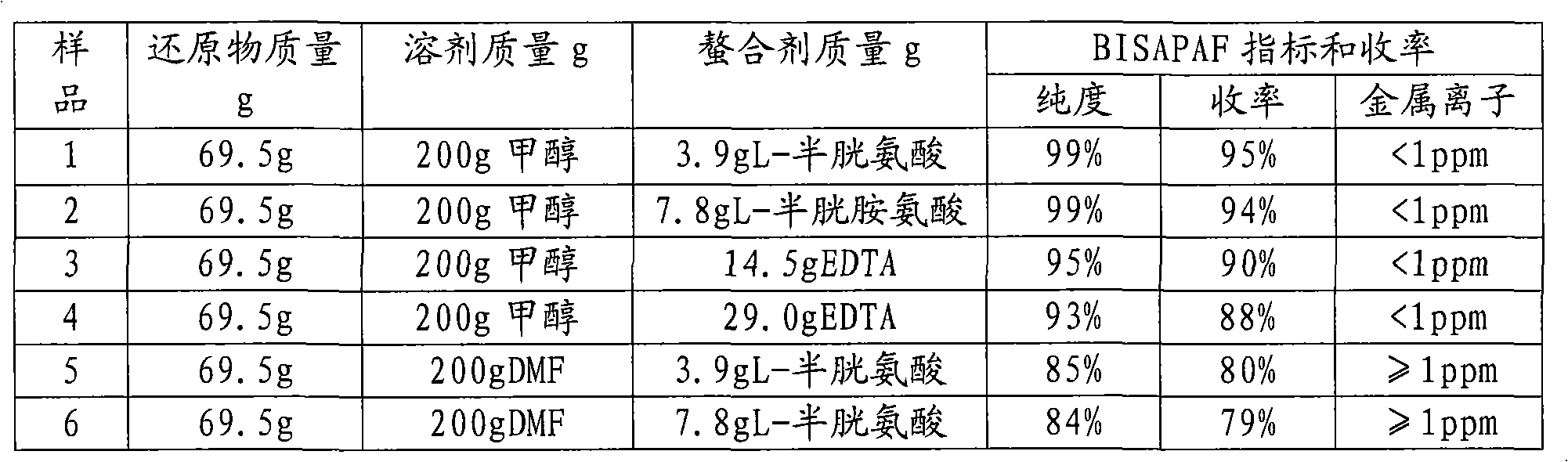

[0051] In this example, 2,2-bis(3-nitro-4-hydroxyphenyl)hexafluoropropane was used as a raw material, dissolved in methanol, and hydrazine hydrate was used as a reducing agent. 2 Reduction of 2,2-bis(3-nitro-4-hydroxyphenyl) hexafluoropropane under the effect of -SnO, to obtain 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane crude product, the A chelating agent is used to remove metal ions from the crude product; 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane after removal of metal ions is purified by vacuum sublimation to obtain the target product.

[0052] The 2,2-bis(3-nitro-4-hydroxyphenyl)hexafluoropropane used in this example was prepared as follows: 67g (0.2mol) 2,2-bis- (4-hydroxyphenyl)hexafluoropropane, slowly add 60 grams of 96wt% concentrated sulfuric acid in a cold water bath and magnetic stirring. After 2,2-bis-(4-hydroxyphenyl) hexafluoropropane was completely dissolved, 60g of mixed acid pre-cooled in an ice bath, the mixed acid was composed of 30g of 96...

Embodiment 2

[0053] The preparation method of present embodiment 2,2-bis(3-amino-4-hydroxyphenyl) hexafluoropropane comprises the following steps:

[0054] (1) Reduction reaction:

[0055] 81.5g 2,2-bis(3-nitro-4-hydroxyphenyl)hexafluoropropane, 3.1gCeO 2 -SnO is added to the industrial methanol solution, under the conditions of the temperature of 60°C-70°C and the pressure of normal pressure, the reducing agent hydrazine hydrate is slowly added dropwise to the solution, and the drop rate of hydrazine hydrate is 10-12mL / min. Stop dripping hydrazine hydrate when bubbles are produced again, the consumption of hydrazine hydrate is 40.7g, filter and remove catalyst CeO after continuing to react for 2h 2 -SnO, add 4 times the volume of deionized water to the filtrate, precipitate 2,2-bis(3-amino-4-hydroxyphenyl)hexafluoropropane, filter, and obtain 2,2-bis The crude product of (3-amino-4-hydroxyphenyl)hexafluoropropane was 69.5 g; the obtained product was detected by HPLC, and its purity was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com