Solidification method and equipment for unearthed bamboo and wooden wares

A technology of bamboo, wood and equipment, which is applied in the field of cultural relics protection and restoration, and can solve problems such as the difficulty in handling large-scale saturated wooden cultural relics, the difficulty in determining the end point of freeze-drying, and the difficulty in determining the eutectic point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

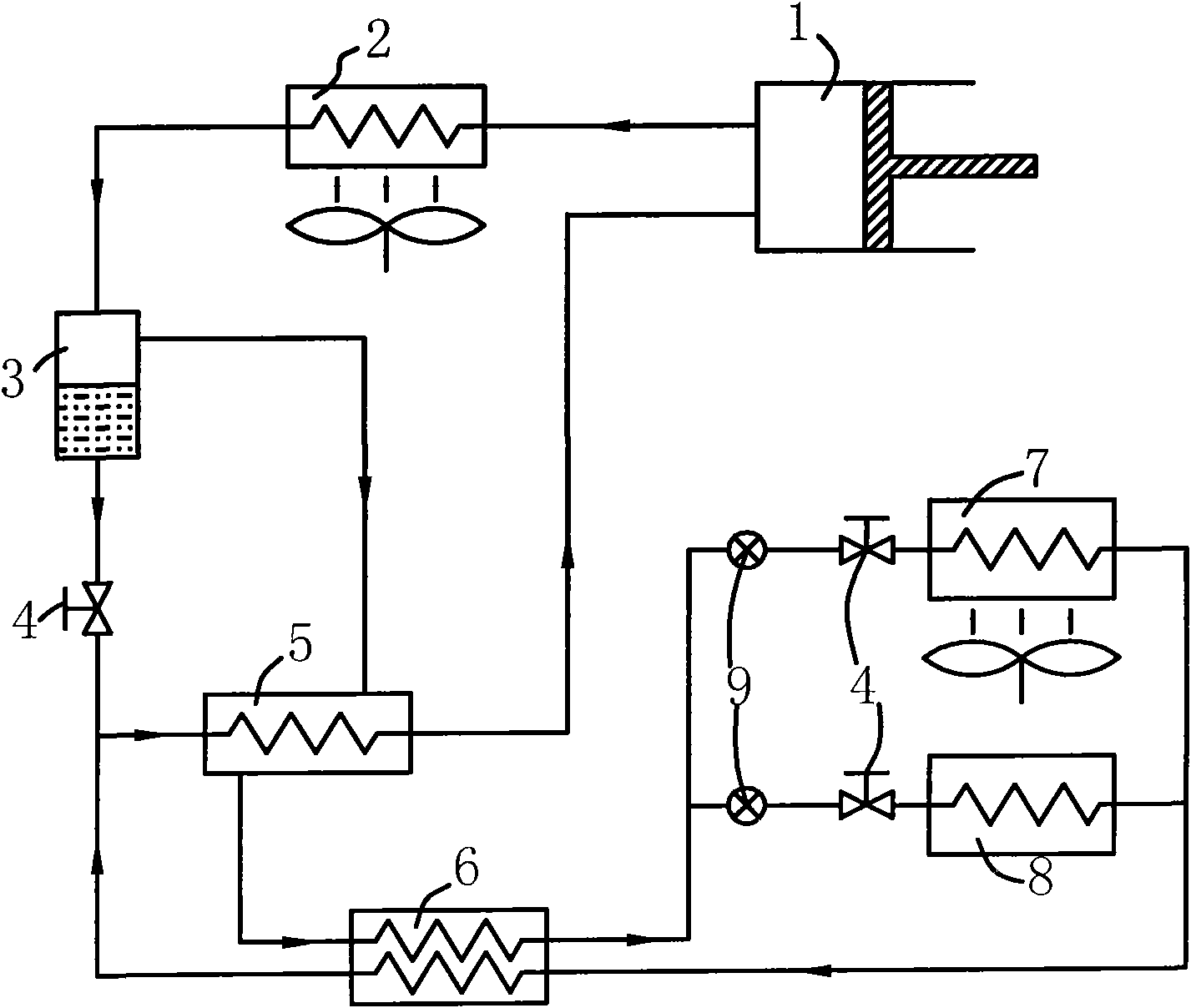

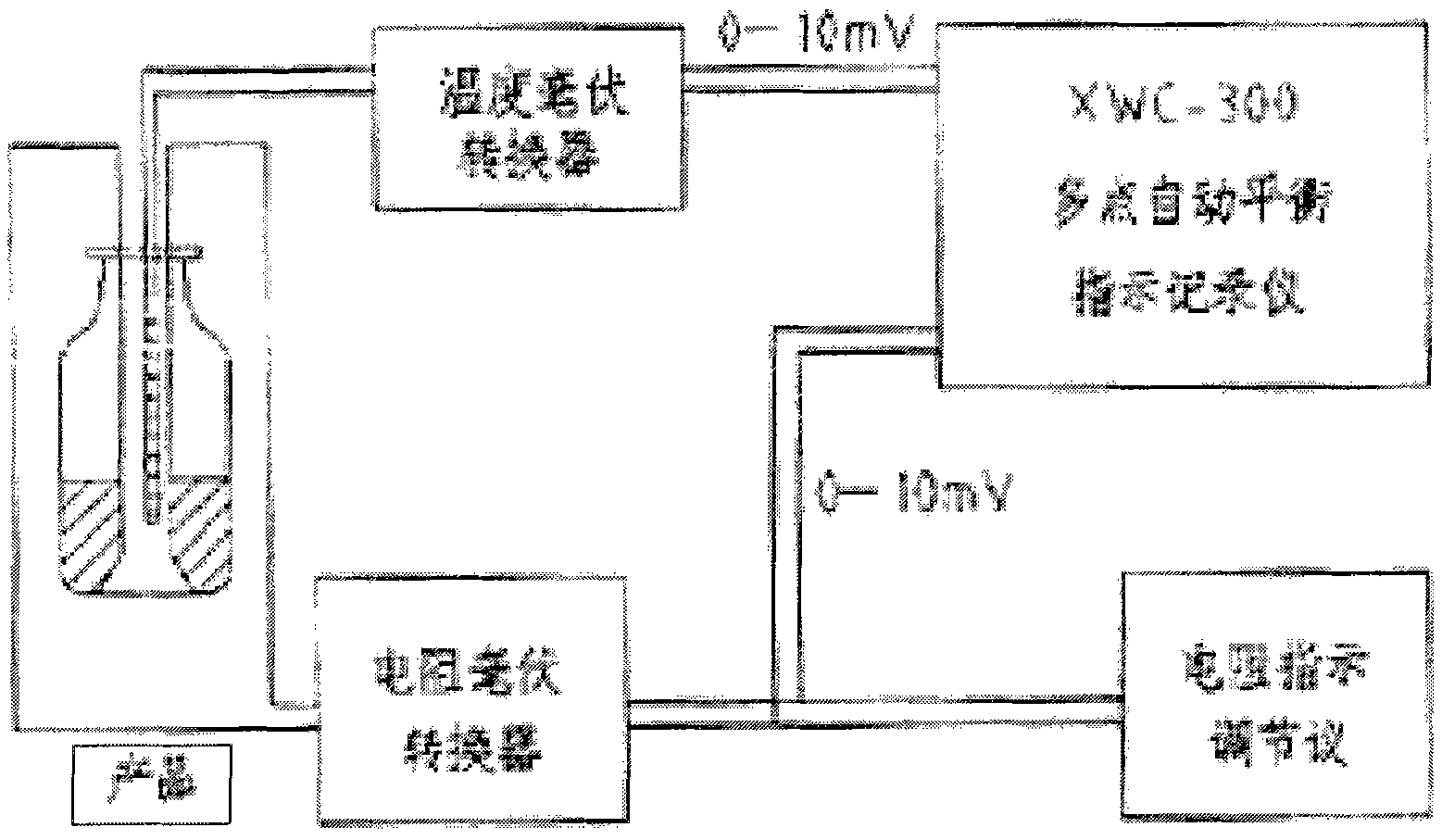

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

[0027] Concrete technical route of the present invention is:

[0028] 1. Hot soak replacement

[0029] This stage is to replace the moisture in the saturated wood components with some dimensional stabilizer, so that the wood components will not be damaged due to the volume expansion of the ice in the wood when the wood components are pre-frozen. The processing steps are as follows:

[0030] (1) Wash the wood components to be treated (if necessary, oxalic acid, sodium dithionite and other reducing agents can be used for preliminary decolorization), then measure the size, balance, take pictures, draw and record;

[0031] (2) Perform necessary binding, clamping, supporting and other work depending on the condition of the utensil, so as not to affect the contact with the dimensionally stable impregnating liquid;

[0032] (3) Immerse the utensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com