Method for separating isopropanol-water compound

A technology of isopropanol and mixture, which is applied in the field of separating isopropanol-water mixture, can solve the problems of corrosive production equipment, high raw material purity requirements, large amount of extractant, etc., and achieve easy operation, easy recovery, and high throughput big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

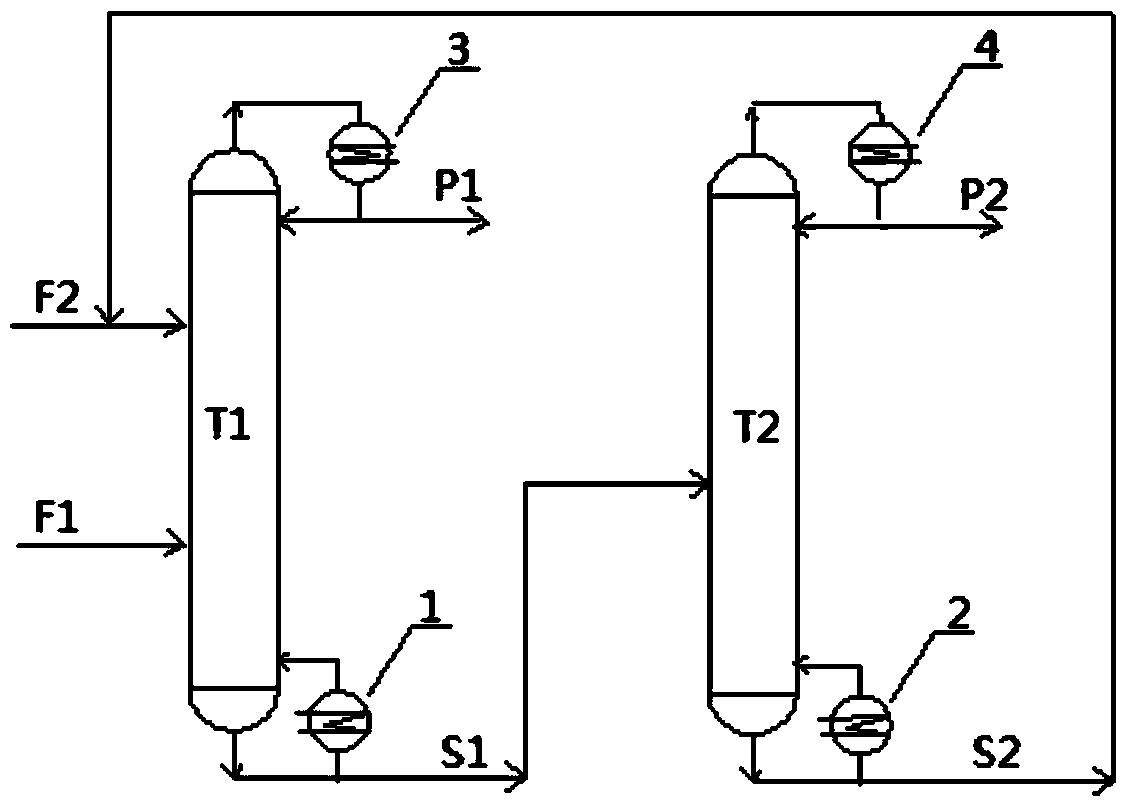

Embodiment 1

[0030] Attached figure 1As shown in the process flow, there are 50 theoretical plates in the rectification tower, the raw materials (5% isopropanol, 95% water, mass fraction, the same below) are fed from the 46th theoretical plate at a flow rate of 1000kg / hr, and the extraction agent is 1 -Ethyl-3-methylimidazole acetate and glycerin volume ratio of 1.5:1 composition of composite extractant, feed from the 5th theoretical plate, operating pressure is 50kPa, solvent ratio 4.0, reflux ratio 1, recovery The operating pressure of the tower is 95kPa. The output at the top of the rectification tower is 993.7kg / hr, the composition: 99.93% isopropanol, 0.07% water, and the yield of isopropanol is 99.3%. The extraction agent is extracted from the bottom of the recovery tower with a water content of 0.13%, and returned to the rectification tower for recycling.

Embodiment 2

[0032] Attached figure 1 As shown in the process flow, there are 25 theoretical plates in the rectification tower, the raw material (25% isopropanol, 75% water) is fed from the 24th theoretical plate at a flow rate of 1000kg / hr, and the extraction agent is 1-butyl-3- Methylimidazole tetrafluoroborate is fed from the second theoretical plate, the operating pressure is 101.3kPa, the solvent ratio is 1, the reflux ratio is 3.0, and the operating pressure of the recovery tower is 80kPa. The output at the top of the rectification tower is 248.1kg / hr, the composition is: 99.95% isopropanol, 0.05% water, and the yield of isopropanol is 99.2%. The extraction agent is extracted from the bottom of the recovery tower with a water content of 0.11%, and returned to the rectification tower for recycling.

Embodiment 3

[0034] Attached figure 1 As shown in the process flow, there are 35 theoretical plates in the rectification tower, the raw materials (45% isopropanol, 55% water) are fed from the 30th theoretical plate at a flow rate of 1200kg / hr, and the extraction agent is 1-ethyl-3- Methylimidazole acetate is fed from the fifth theoretical plate, the operating pressure is 85kPa, the solvent ratio is 0.8, the reflux ratio is 0.5, and the operating pressure of the recovery tower is 75kPa. The output at the top of the rectification tower is 537.5kg / hr, the composition: 99.96% isopropanol, 0.04% water, and the yield of isopropanol is 99.5%. The extraction agent is extracted from the bottom of the recovery tower with a water content of 0.10%, and returned to the rectification tower for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com