Method for producing milk beverage with added garden stuff fiber

A fruit and vegetable fiber and production method technology, which is applied in the field of dairy product processing, can solve the problems of lack of homogeneity, long mixing time, and large energy loss, achieve good sterilization effects, save energy consumption, and save production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

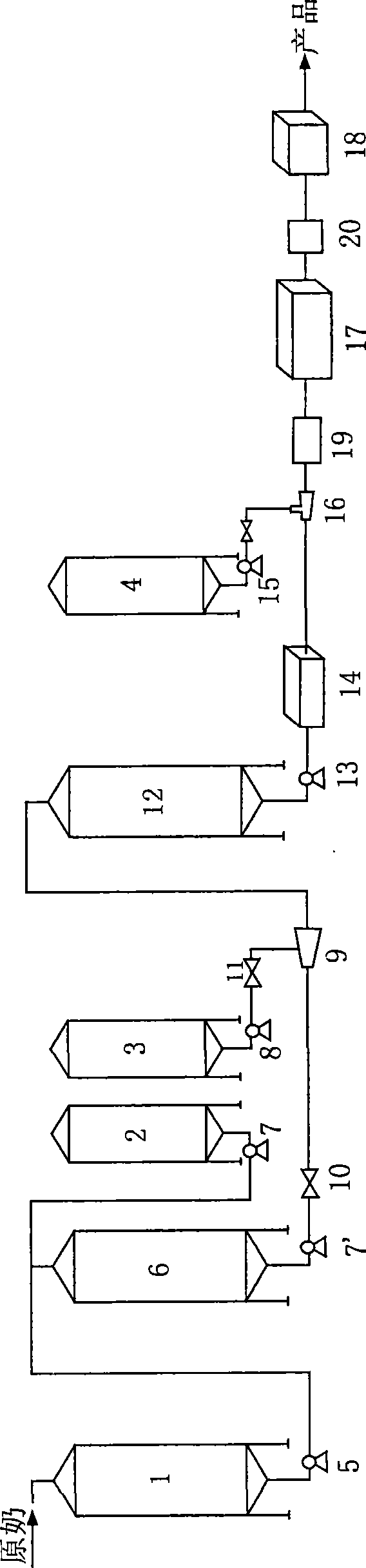

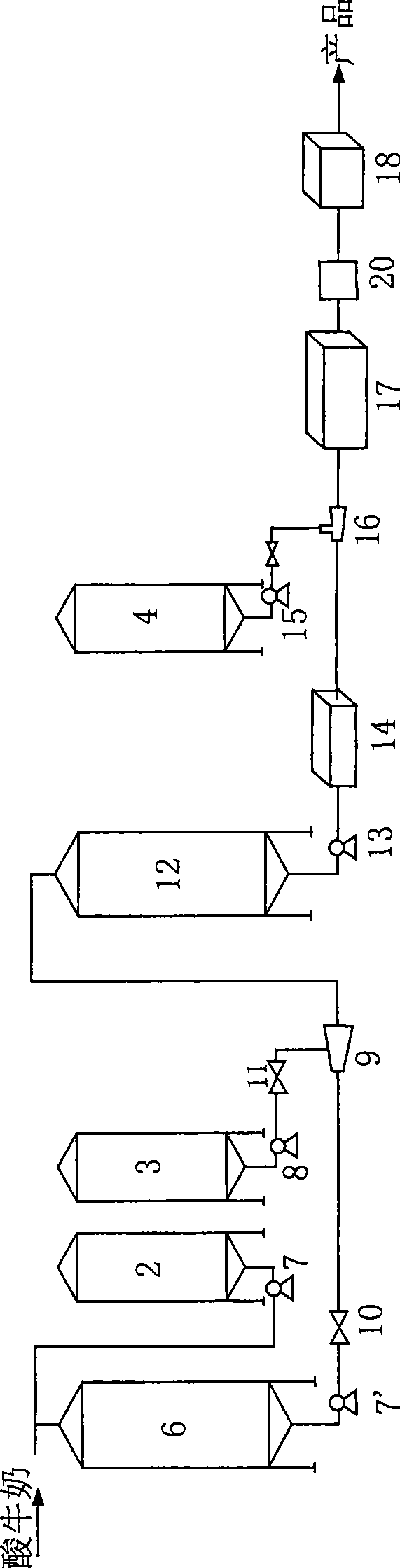

Image

Examples

Embodiment 1

[0077] Embodiment 1: the production of orange-flavored sour milk drink

[0078] Produce a kind of orange-flavored sour milk drink according to the following raw material proportioning (calculated per 100 grams of product):

[0079] 35 grams of milk, 6.0 grams of white sugar, 0.75 grams of fructose syrup, 0.012 grams of acesulfame potassium, 0.20 grams of citric acid, 0.24 grams of lactic acid, 0.35 grams of sodium carboxymethyl cellulose, 5 grams of orange pulp The actual content of the particles), 0.05 grams of orange flavor, and the balance of water.

[0080] Raw material standard:

[0081]Raw material of minced orange: purchased from Cargill Investment (China) Co., Ltd. Flavor / Juice System, wherein the content of minced orange (mainly the vesicle of orange pulp) is ≥75%, the length of minced orange is 3-8mm, and the width is 0.05-1mm. Soluble solids Brix (20°C refractometer method)%≤20, sugar-acid ratio Ratio 10-20;

[0082] All raw materials meet the requirements of rel...

Embodiment 2

[0096] Embodiment 2: Preparation of grapefruit-flavored lactic acid bacteria milk drink

[0097] Produce a kind of grapefruit-flavored lactic acid bacteria milk beverage according to the following raw material ratio (calculated per 100 grams of product):

[0098] 50 grams of yogurt, 9.0 grams of white sugar, 0.005 grams of acesulfame potassium, 0.00014 grams of neotame, 0.12 grams of citric acid, 0.10 grams of lactic acid, 0.35 grams of pectin, 1 gram of grapefruit puree (based on the actual content of grapefruit puree particles in beverage products meter), 0.2 g of grapefruit flavor essence, and the remainder of water.

[0099] Raw material standard:

[0100] Grapefruit puree: purchased from Cargill Investment (China) Co., Ltd. Flavor / Juice System, in which grapefruit puree (mainly the capsule skin of grapefruit pulp) has a particle content of ≥75%, the length of grapefruit puree is 3-8 mm, and the width is 0.05 mm. ~2mm, soluble solids Brix (20℃ refractometer method)%≤20, ...

Embodiment 3

[0112] Embodiment 3: preparation of carrot milk drink

[0113] A kind of carrot milk drink is produced according to the following raw material ratio (calculated per 100 grams of product):

[0114] 40 grams of milk, 5.0 grams of white sugar, 0.5 grams of fructose syrup, 0.12 grams of sodium citrate, 0.2 grams of carrageenan, 0.05 grams of xanthan gum, 8 grams of carrot puree, 0.3 grams of carrot essence, and the rest of water.

[0115] Raw material standard:

[0116] Carrot puree: purchased from Xiamen Dachuan Company, mainly crushed and squeezed carrots, wherein the content of carrot fiber particles is ≥75%, the length of carrot fiber particles is 1-5mm, the width is 0.05-1mm, and the soluble solids are ≥39 BX. Acid 1.3±0.3%, total content of amino acid nitrogen ≥125mg / 100g, pH 4.0~4.5;

[0117] All raw materials meet the requirements of relevant quality standards.

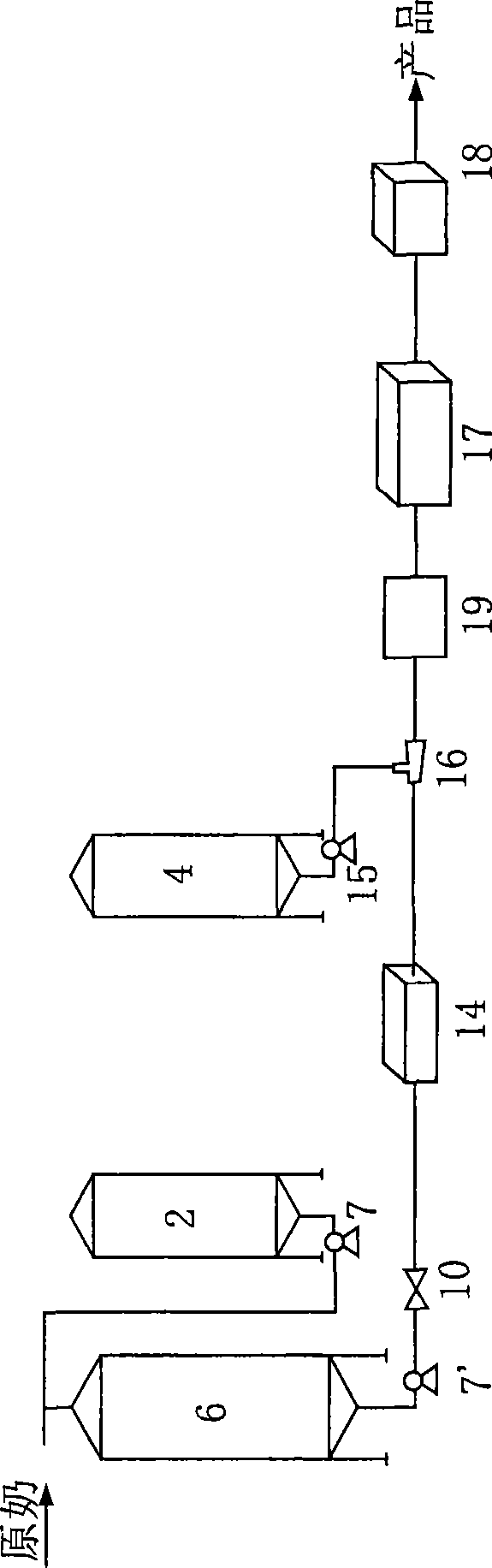

[0118] See image 3 As shown, it is a schematic diagram of the production process of the carrot milk drink ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com