UV curing machine and control method thereof

A control method and curing machine technology, applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as fire, damage, and long exposure time of UV lamps, and achieve the effects of saving production energy and preventing overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

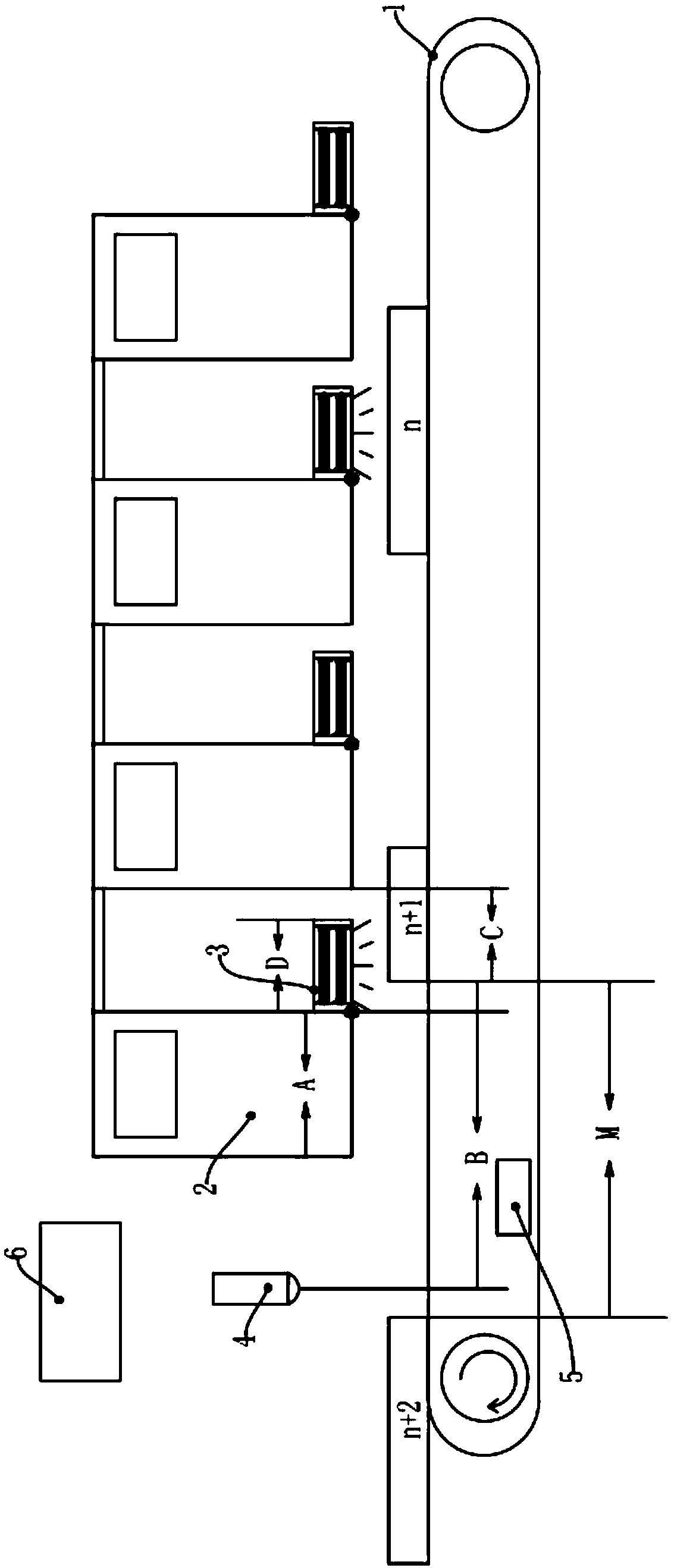

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0026] A UV curing machine, including a conveyor belt 1, a plurality of hanging cages 2, a plurality of UV lamps 3, electric eyes 4, a bottom belt servo driver 5 and a PLC controller 6;

[0027] A plurality of said hanging cages 2 are equidistantly arranged above the conveyor belt 1; each said UV lamp 3 is arranged between two said hanging cages 2, and one end of said UV lamp 3 is connected to said cage 2;

[0028] The electric eye 4 is arranged on the left side of a plurality of the hanging cages 2, and the electric eye 4 is electrically connected to the PLC controller 6;

[0029] The bottom belt servo driver 5 is arranged on the conveyor belt 1 , and the bottom belt servo driver 5 is electrically connected to the PLC controller 6 .

[0030] exist figure 1 The left side of the conveyor belt 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com