Production methods of fire-fighting monoammonium phosphate and ABC dry powder extinguishing agent

A technology of dry powder fire extinguishing agent and monoammonium phosphate, which is applied in the direction of phosphate, fire prevention equipment, phosphorus oxyacid, etc., can solve the problems of large fluctuations in production indicators, unstable quality control, and equipment wear and tear, and achieve good fluidity and energy saving The effect of crushing energy consumption, saving production energy consumption and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

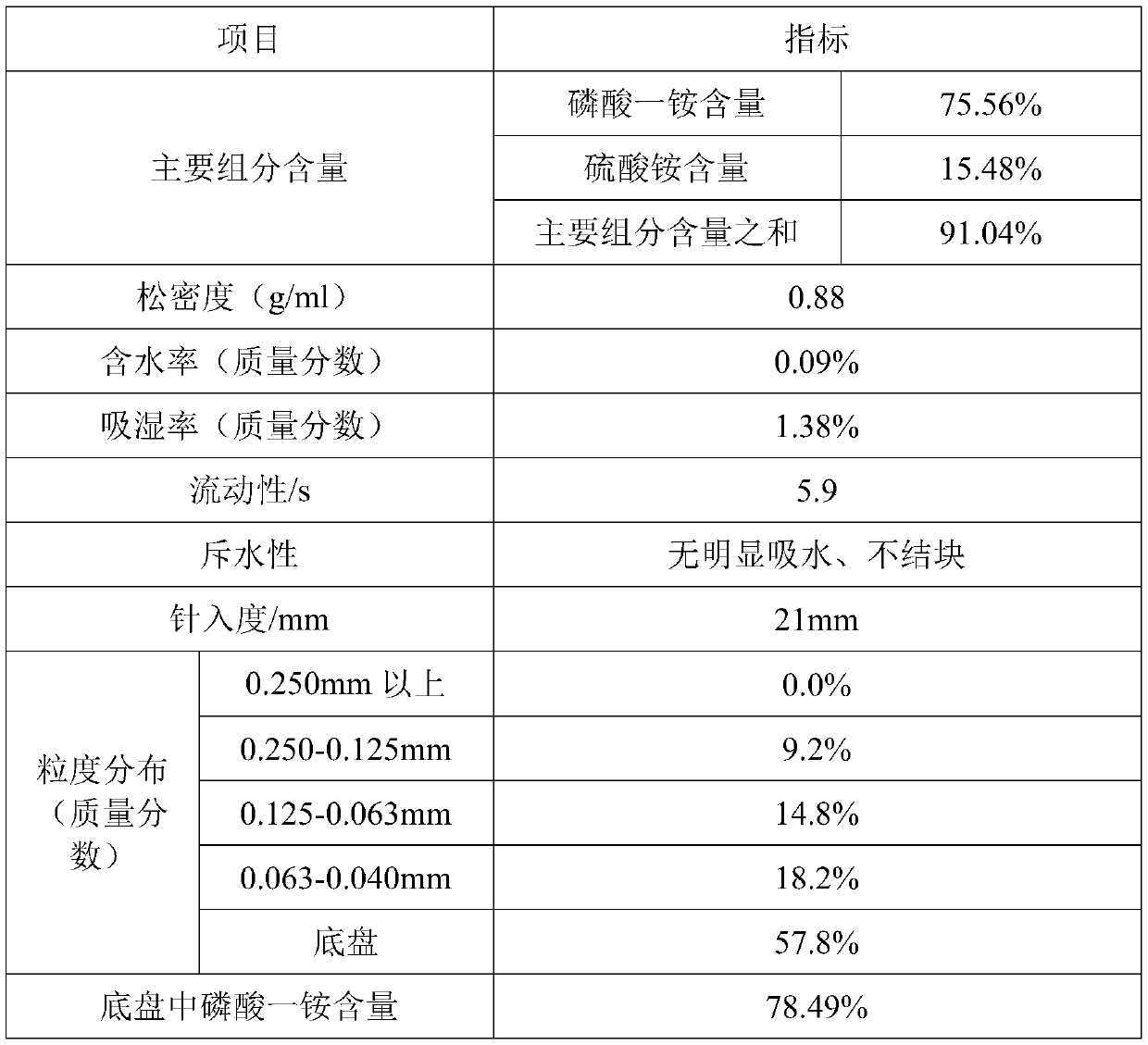

Embodiment 1

[0076] The concentration (in P 2 o 5 Total) is mixed with 26% half-water wet-process phosphoric acid and sulfuric acid to control the mixed acid solution SO 3 / P 2 o 5 = 19.5%;

[0077] Add liquid ammonia to the obtained mixed acid, neutralize until the pH is 4.4, take the neutralized slurry, directly carry out atomization and drying, and obtain monoammonium phosphate for fire protection. After analysis, the content of monoammonium phosphate in the product 81.45%, the content of ammonium sulfate is 16.08%, and the ratio of passing through a 0.04mm standard sieve is 60.4%;

[0078] The fire-fighting monoammonium phosphate obtained in the above steps is batched with other auxiliary materials, and the formula is as follows:

[0079] Monoammonium Phosphate for Fire Fighting ammonium sulfate Silica Quartz sand Mica white clay silicone oil iron yellow 930kg 5kg 20kg 25kg 10kg 10kg 8kg 0.02kg

[0080] Measure all the raw materials e...

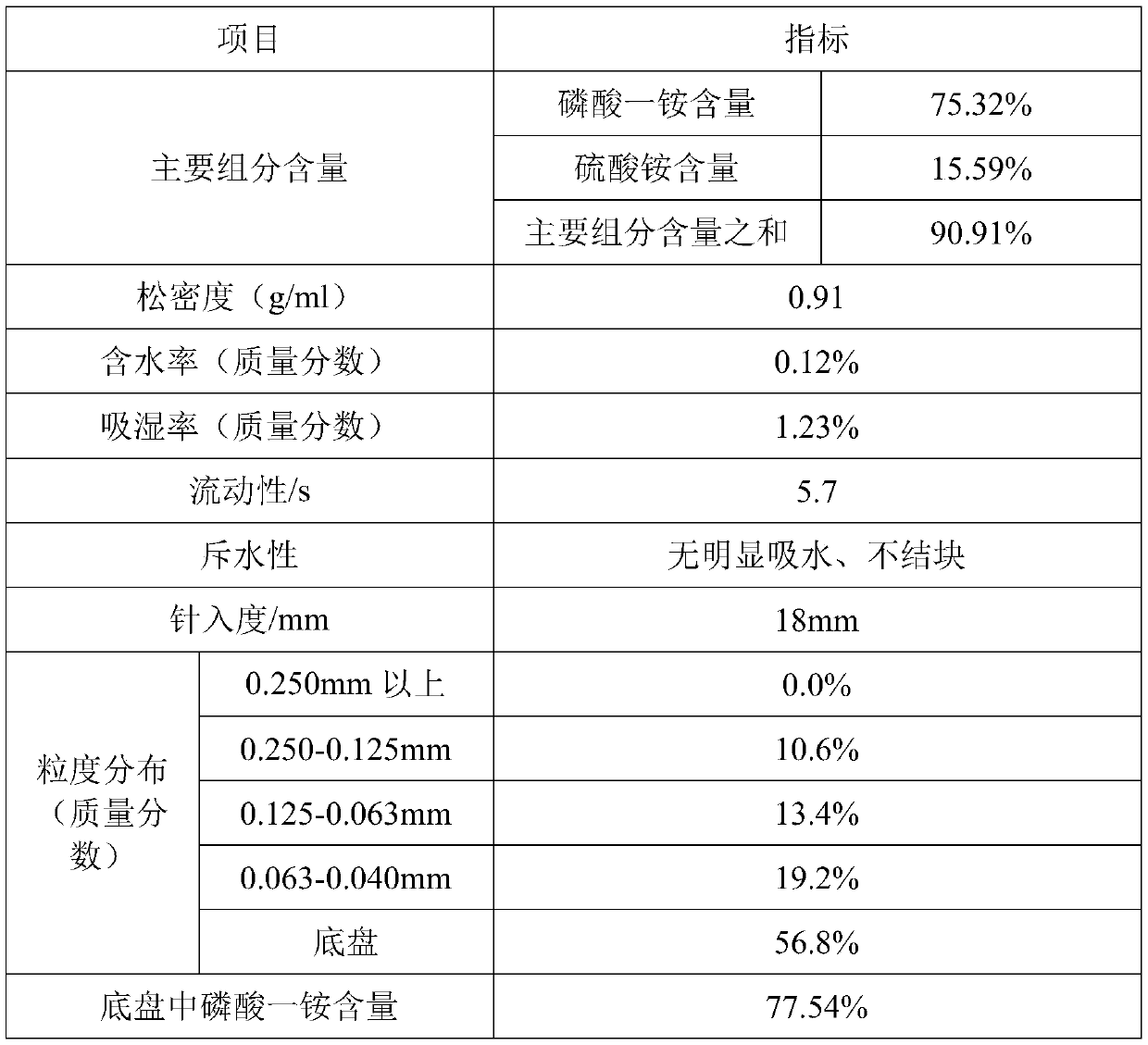

Embodiment 2

[0084] The concentration (in P 2 o 5 Total) is 38% semi-water wet-process phosphoric acid mixed with sulfuric acid to control the mixed acid solution SO 3 / P 2 o 5 = 1.7%;

[0085] Add liquid ammonia to the obtained mixed acid, neutralize until the pH is 4.4, take the neutralized slurry, directly atomize and dry to obtain monoammonium phosphate for fire fighting; after analysis, the content of monoammonium phosphate in the product 91.85%, the content of ammonium sulfate is 1.55%, and the ratio of passing through a 0.04mm standard sieve is 63.6%;

[0086] The fire-fighting monoammonium phosphate obtained in the above steps is batched with other auxiliary materials, and the formula is as follows:

[0087] Monoammonium Phosphate for Fire Fighting ammonium sulfate Silica Quartz sand Mica white clay silicone oil iron yellow 820kg 140kg 20kg 10kg 5kg 5kg 7kg 0.02kg

[0088]Measure all the raw materials except silicone oil according...

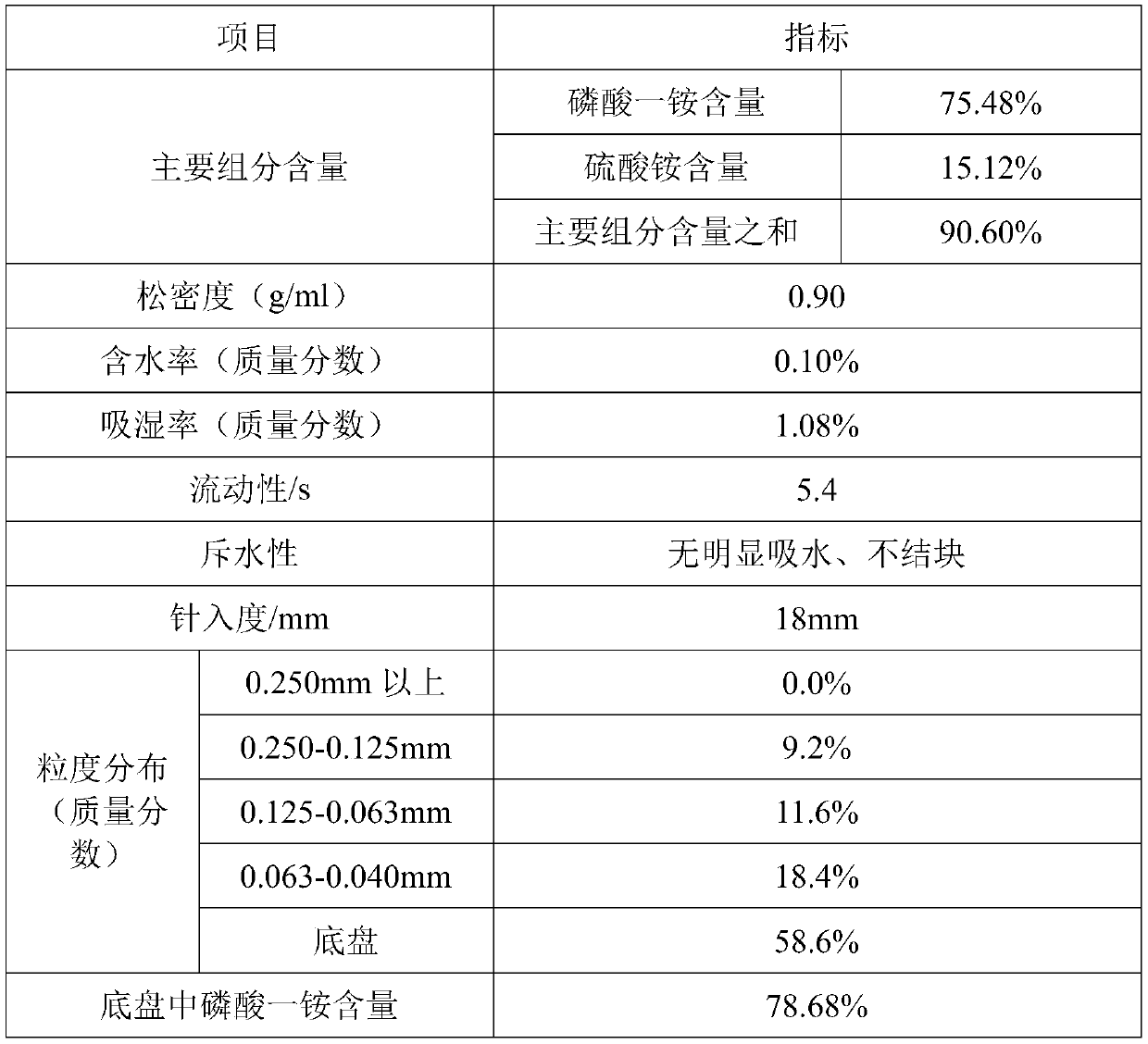

Embodiment 3

[0092] The concentration (in P 2 o 5 30% semi-water wet-process phosphoric acid mixed with ammonium sulfate (99% purity), the amount of ammonium sulfate is expressed as SO 3 meter, control the mixing ratio SO 3 / P 2 o 5 = 10.8%;

[0093] Add liquid ammonia in the mixture that obtains, neutralize to pH be 4.3, get the slurry after neutralization, directly carry out atomization, drying, obtain the monoammonium phosphate for fire-fighting; After analysis, the content of monoammonium phosphate in the product is 88.79%, the content of ammonium sulfate is 9.59%, and the proportion of 0.04mm standard sieve is 61.2%;

[0094] The fire-fighting monoammonium phosphate obtained in the above steps is mixed with other auxiliary materials, and the formula is as follows.

[0095] Monoammonium Phosphate for Fire Fighting ammonium sulfate Silica Quartz sand Mica white clay silicone oil iron yellow 860kg 75kg 20kg 35kg 5kg 5kg 7kg 0.02kg

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com