Graded porous honeycomb nickel oxide microsphere and preparation method thereof

A hierarchical porous and honeycomb-shaped technology, applied in the direction of nickel oxide/nickel hydroxide, etc., can solve the problems of high cost, high energy consumption, cumbersome preparation process, etc., and achieve the effects of saving production energy, improving production efficiency and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

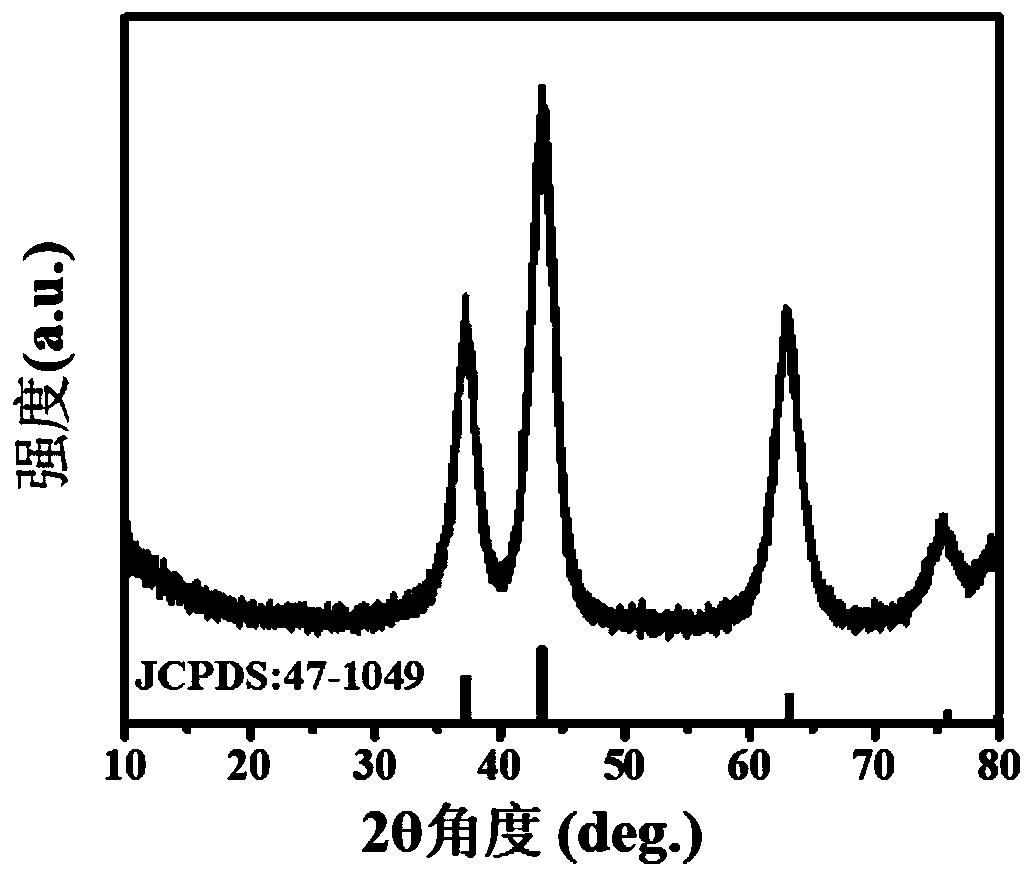

[0025] The invention provides a preparation method of hierarchical porous honeycomb nickel oxide microspheres, comprising the following steps:

[0026] Mix nickel sulfate hexahydrate, urea, water and glycerin to obtain a mixed solution;

[0027] performing a hydrothermal reaction on the mixed solution to obtain a precursor product;

[0028] The precursor product is calcined to obtain the hierarchical porous honeycomb nickel oxide microspheres.

[0029] The invention mixes nickel sulfate hexahydrate, urea, water and glycerol to obtain a mixed solution.

[0030] In the present invention, the mass ratio of nickel sulfate hexahydrate to urea is preferably (0.24-0.28):(0.06-0.60), more preferably (0.25-0.26):(0.48-0.60).

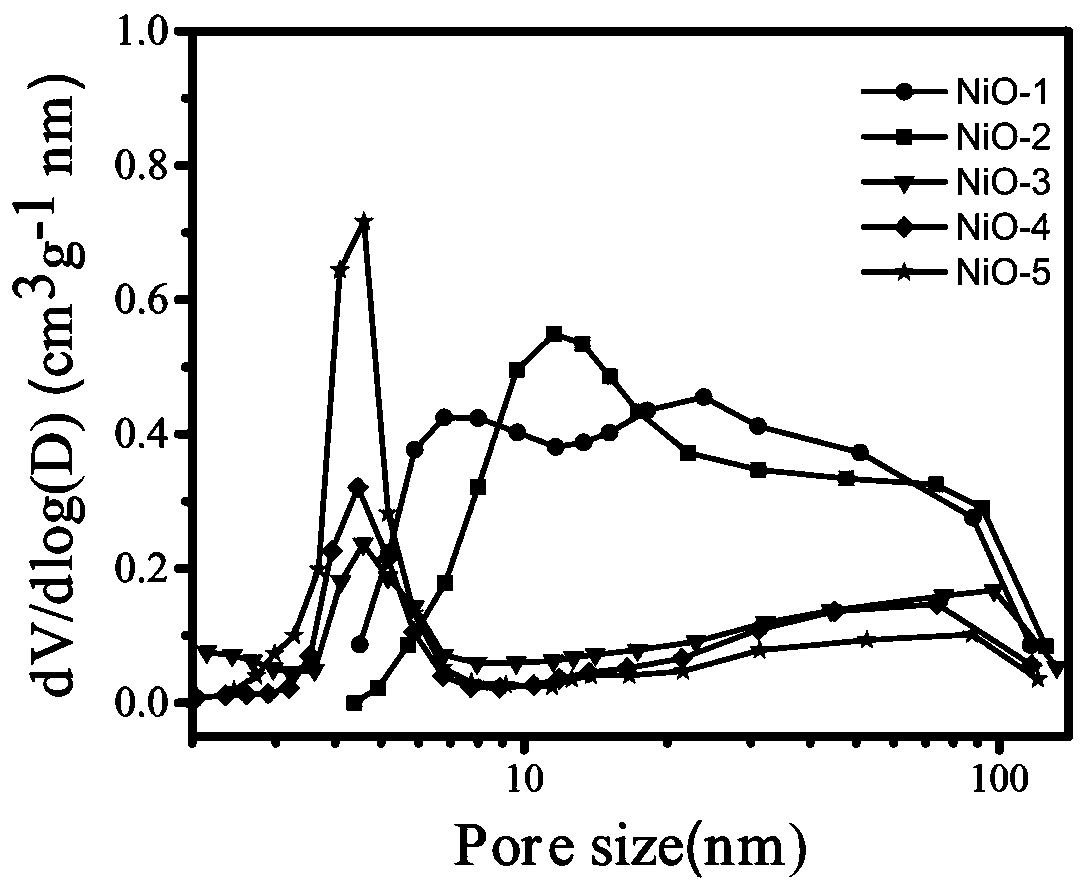

[0031] In the present invention, the volume ratio of glycerol to water is preferably (0-18):(36-18), more preferably 1:35, 1:5, 1:2 or 1:1.

[0032] In the present invention, the ratio of the total solid mass of nickel sulfate hexahydrate and urea to the total...

Embodiment 1

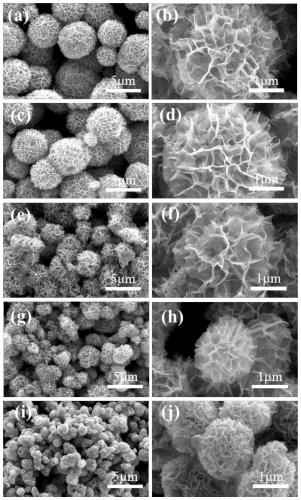

[0043] Dissolve 0.263g of nickel sulfate hexahydrate into 36mL of deionized water at room temperature to obtain a green clear solution, then add 0.48g of urea to the above solution and stir well. The synthesized mixture was transferred to a Teflon-lined stainless steel autoclave and hydrothermally heated at 140 °C for 1 h. After the hydrothermal reaction was completed, the green product was collected by centrifugation after cooling to room temperature, washed three times with deionized water and absolute ethanol, and dried in an oven at 60°C for 12 hours to obtain a green product (precursor product). In order to remove residual intermediate products, the sample was heat-treated in a tube furnace at 400°C for 20 hours to collect hierarchical porous honeycomb nickel oxide microspheres, named NiO-1, with a specific surface area of 131.1 m 2 / g.

Embodiment 2

[0045] Dissolve 0.263g of nickel sulfate hexahydrate in 35mL of deionized water at room temperature to obtain a green clear solution, then add 0.48g of urea to the above solution, add 1mL of glycerol and stir until uniform. The above liquid was transferred to a polytetrafluoroethylene-lined stainless steel autoclave, and hydrothermally heated at 140°C for 1 hour. After the hydrothermal reaction was completed, the green product was collected by centrifugation after being cooled to room temperature, washed three times with deionized water and absolute ethanol, and dried in an oven at 60°C for 12 hours to obtain a green product. The resulting product was heat-treated in a tube furnace at 400°C for 20 hours, and the porous honeycomb nickel oxide microsphere product was collected, named NiO-2, with a specific surface area of 135.6m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com