Non-axial screw conveyor for burning refuse

A shaftless screw conveying and garbage incineration technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of garbage odor emission, heat leakage, arching, etc., to increase the effective space and avoid the phenomenon of material blocking , to ensure the effect of uniform delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

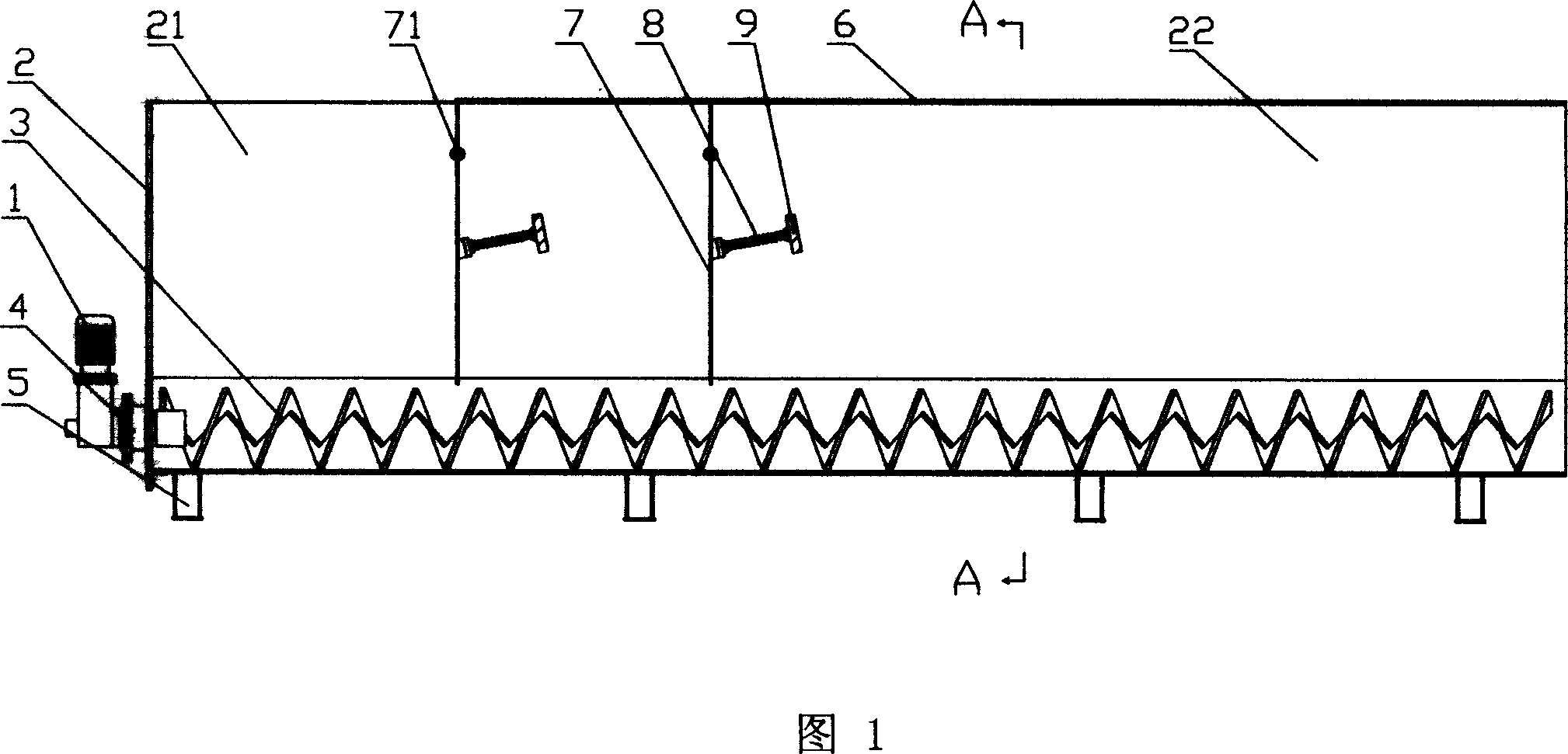

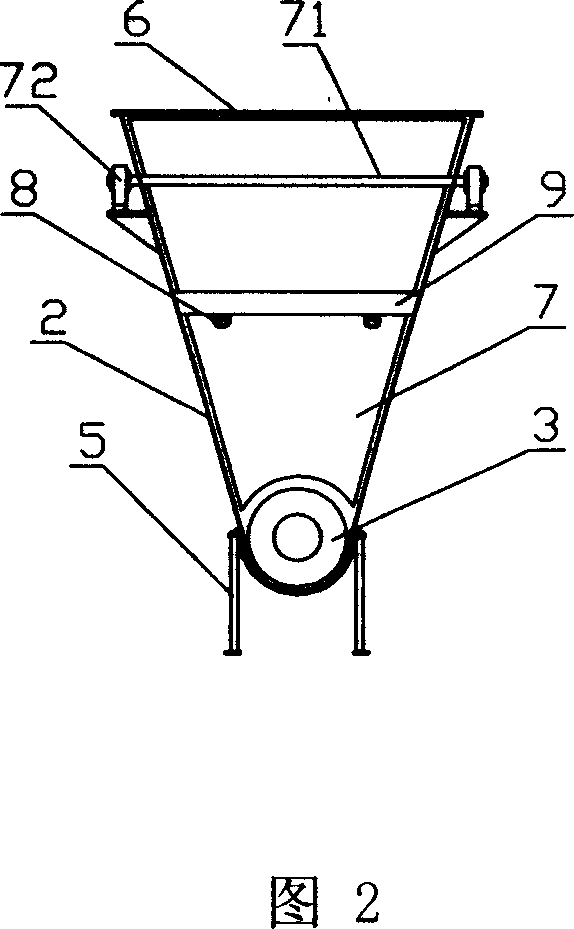

[0014] As shown in Figure 1 and Figure 2, it is an embodiment of the shaftless screw conveyor for waste incineration of the present invention, including a motor 1, a V-shaped bin body 2 and a conveying device driven by a motor in the bin body 2. In the example, the conveying device adopts the shaftless spiral blade 3, and the shaftless spiral blade 3 is connected on the rotating shaft of the motor 1. In the figure, 4 is the seat body of the fixed motor, and 5 is the supporting leg. The warehouse body 2 includes the feeding section 21 and the The conveying section 22 is provided with a cover plate 6 at the top of the conveying section 22, and two baffles 7 are arranged at the end of the feeding section 21 in the silo body conveying section 22 for keeping out the wind and balancing garbage, and the baffles 7 are installed on the rotating shaft 71, the rotating shaft 71 is flexibly transferred to the bearing seat 72 located on the two side walls of the warehouse body, the fixing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com