Material bag shaping and flattening device

A material bag and pressure roller technology, applied in the field of material bag shaping and flattening device, can solve the problems of complex structure, unadjustable pressure roller height and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below according to the drawings and embodiments.

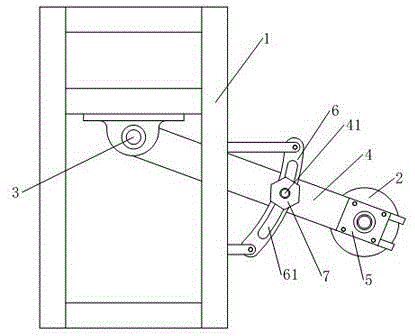

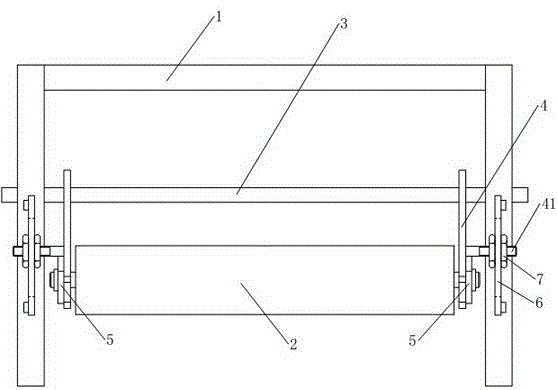

[0013] Such as figure 1 and figure 2 As shown, a material bag shaping and flattening device described in the embodiment of the present invention includes a frame 1 and a horizontally arranged pressing roller 2, a rotatable rotating shaft 3 is hoisted below the frame 1, and on the rotating shaft 3 Two pivoting arms 4 are vertically connected, and the end of the pivoting arm 4 away from the rotating shaft 3 is provided with a bearing 5 with a seat, and the bearing 5 with a seat 5 is connected with the pressure roller 2; both sides of the frame 1 Guide rails 6 are respectively fixed, and the guide rails 6 have arc-shaped guide grooves 61. The rotating arm 4 is provided with guide posts 41 with external threads, and the guide posts 41 run through the guide grooves 61; Tightening nuts 7 matched with the guide posts 41 are provided on both sides of the guide rail 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com