Automatic flow regulating device and method for stem pressing machines

A technology of automatic adjustment and stem pressing machine, which is used in the treatment of tobacco, tobacco, and applications, and can solve the problems of lack of automatic adjustment function of incoming material flow, inability to meet the requirements of lean production, and failure of incoming material flow to change accordingly. To achieve good promotion and application prospects, good industrial application value, and the effect of preventing material blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

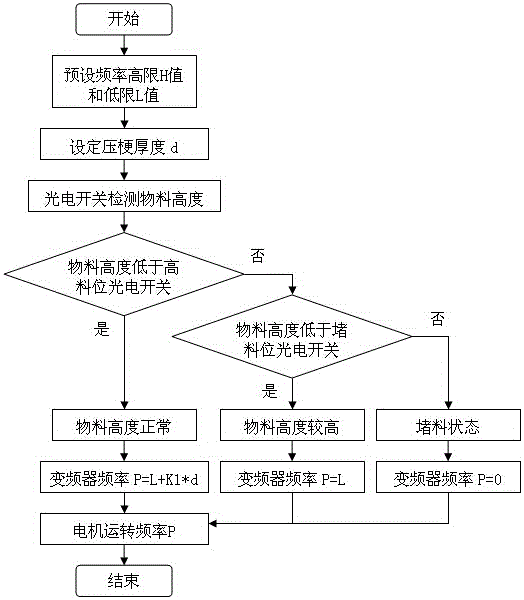

[0027] The technical requirement of the thickness d of the stem is in the range of 1.0-2.2mm, and the coefficient K1 is optimized to be 10;

[0028] First, set the upper limit H value of the frequency converter 3 to 50HZ, and the lower limit L value to 30HZ;

[0029] When the current production process requires the thickness d of the stem to be 1.4mm, set the corresponding value in the monitoring system;

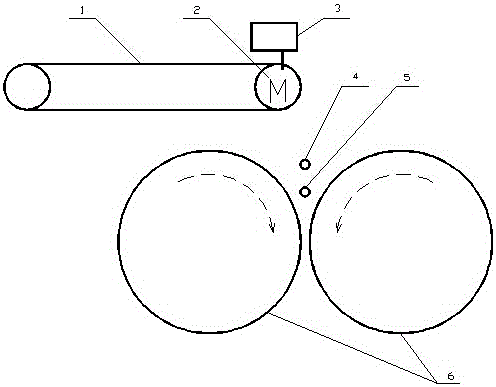

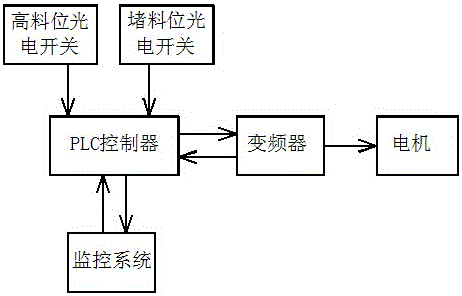

[0030] During work, the feed conveyor belt 1 sends the tobacco stems to the gap between the rollers 6, and the high material level photoelectric switch 5 and the blocking material level photoelectric switch 4 monitor the material accumulation in real time;

[0031] When the material height is lower than the high material level photoelectric switch 5, it is judged that the material accumulation is in the normal range, and the output frequency of the frequency converter 3 is P=L+K1*d=30+10*1.4=44HZ, if the pressure stem thickness d changes, The output frequency of the inverte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com