Novel door seal rubber sleeve cutting device

A technology for cutting devices and rubber sleeves, which is applied in metal processing and other directions, can solve the problems affecting the cutting speed and dimensional accuracy of door seal rubber sleeves, endangering the life safety of operators, and poor safety of cutting devices, so as to achieve good dimensional accuracy, The effect of high safety and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

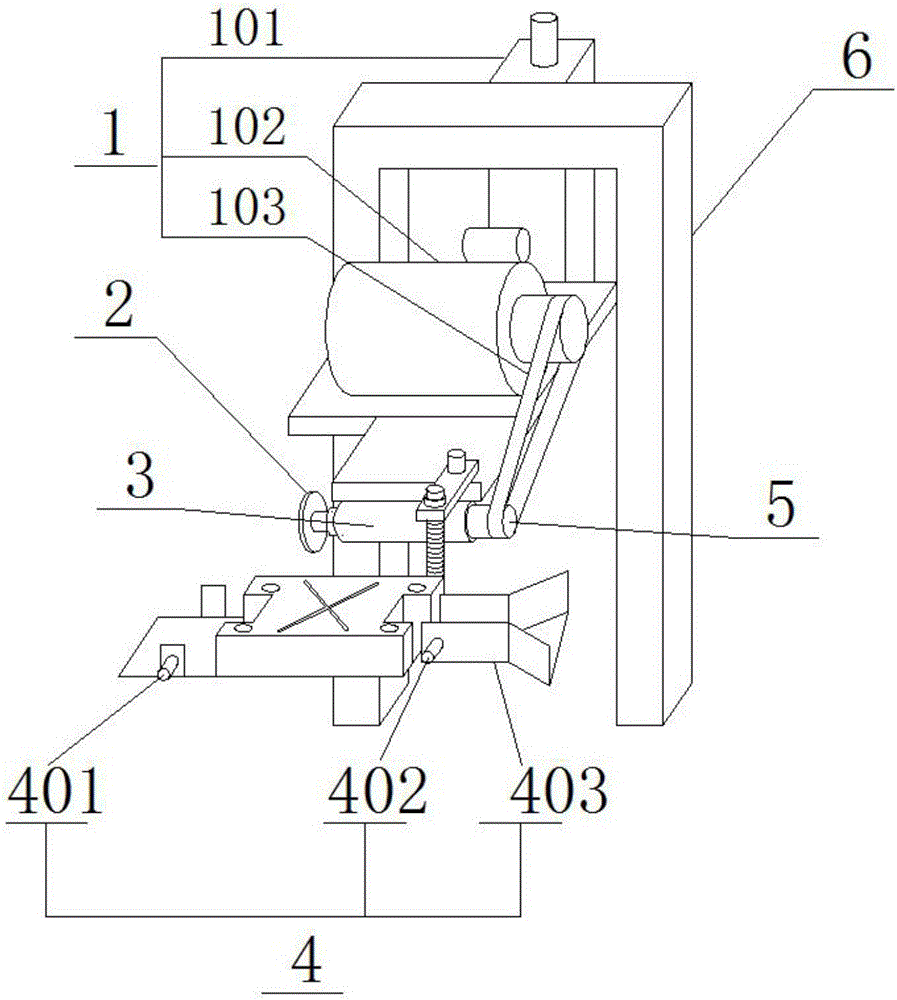

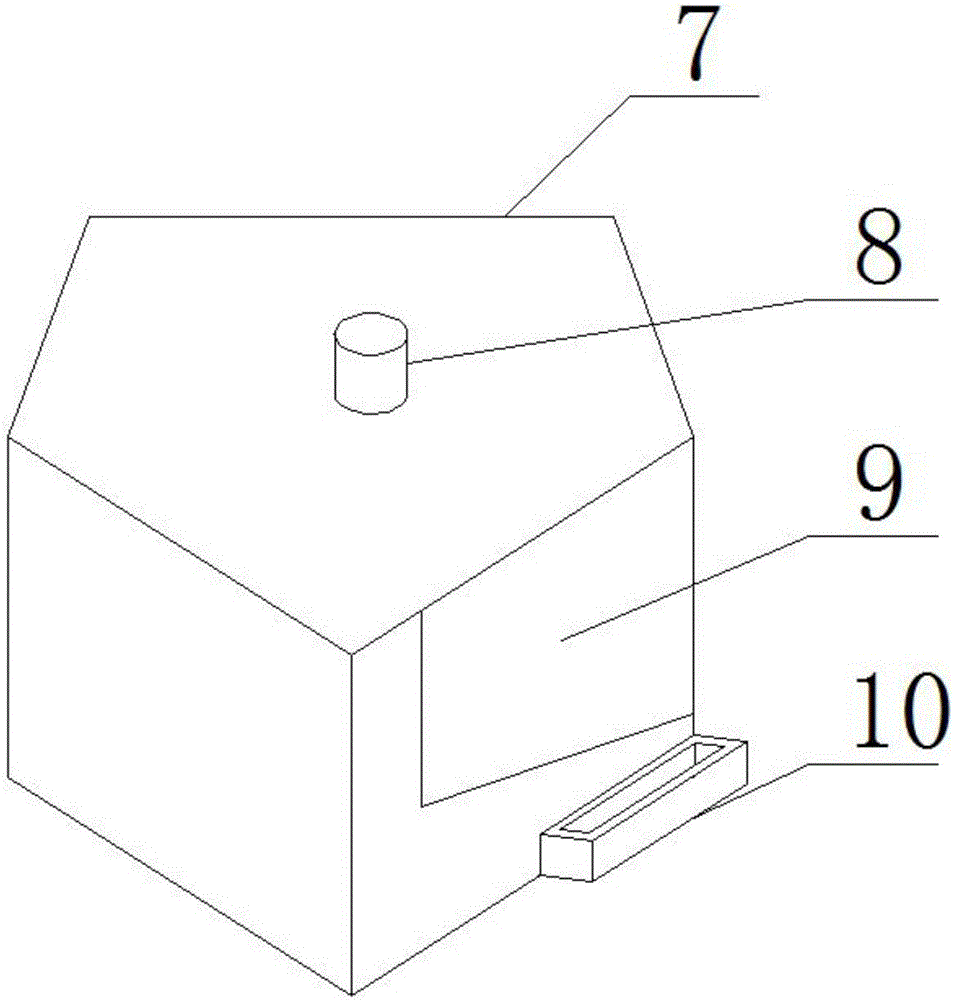

[0015] See the accompanying drawings: a new type of door seal rubber sleeve cutting device, which is characterized in that it includes cutting devices (2, 3, 4, 5), a power device 1, a safety protection device 7 and a support frame 6, and the cutting device (2, 4, 5) 3, 4, 5) including the cutter assembly (2, 3, 5) and the cutting mold 4, the cutter assembly (2, 3, 5) includes the cutter 2, the brake device 3 and the rotating shaft 5, and the cutting mold 4 enters the die There is a photoelectric sensor 402 and a guide 403. There is a photoelectric sensor 401 at the exit of the cutting mold 4. The power device 1 includes a telescopic device 101, a power motor 102 and a transmission belt 103. The telescopic device 101 controls the safety protection device 7 through a connector. , the power motor 102 drives the cutter assembly (2, 3, 5) through the transmission belt 103, and the trapezoidal monitoring window 9 and the alarm device 8 are arranged on the safety protection device 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com