Gear adjusting type injection allocation device for polymer injection well

A technology of dispenser and polymer injection well, which is applied in wellbore/well components, production fluids, earth-moving drilling and other directions, can solve the problems of easy blockage of the outlet, inconvenient adjustment of polymer injection amount, complex structure, etc. The effect of convenient flow adjustment, simple structure and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

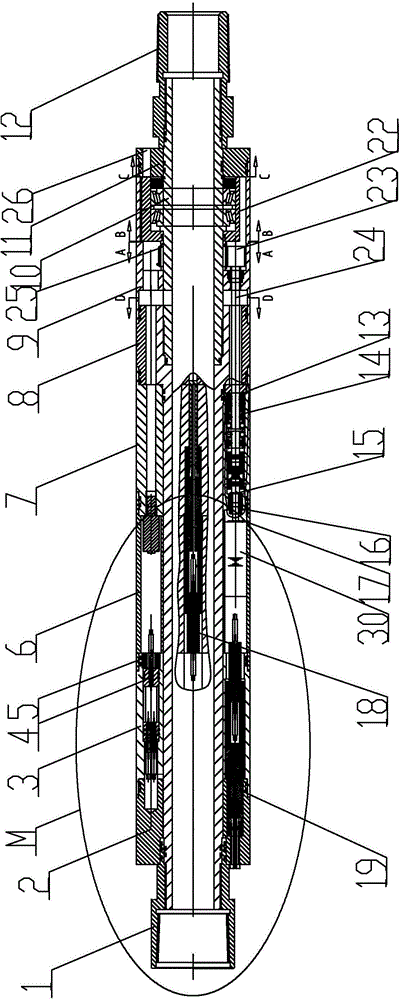

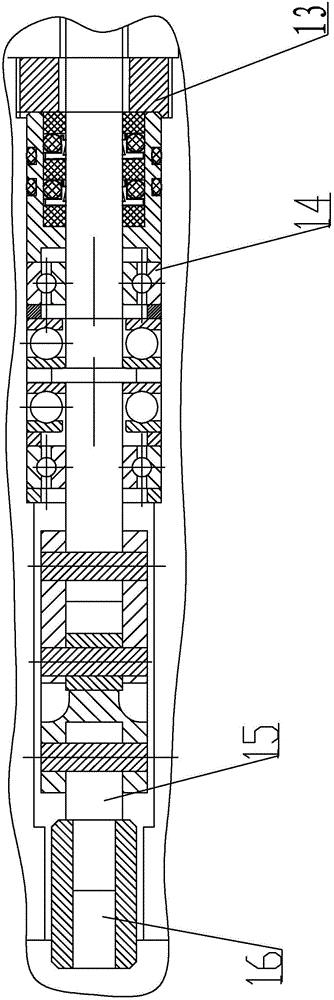

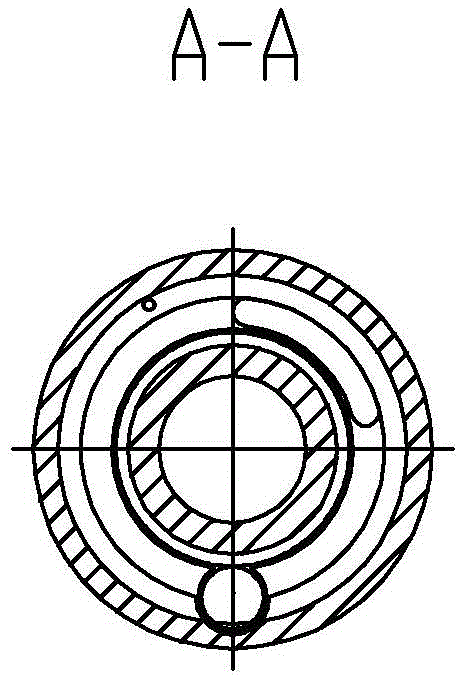

[0010] Specific implementation mode one: combine Figure 1-Figure 7 Describe this embodiment, a gear-adjustable dispenser for polymer injection wells in this embodiment includes an upper joint body 1, an upper cable body 2, a pin body 3, a motor housing 6, a bearing housing 7, and a connecting body 8. Upper outer casing 9, central tube 10, lower outer casing 11, lower joint body 12, motor 30, pinion gear 23, pinion gear shaft 24 and bull gear 25, and the outer surface of the connecting body 8 is installed sequentially from top to bottom There are upper joint body 1, upper cable body 2, pin body 3, motor housing 6 and bearing housing 7, connecting body 8 and upper joint body 1 are connected by thread, and the outer surface of central tube 10 is from top to bottom. The upper outer casing 9, the lower outer casing 11 and the lower joint body 12 are installed in sequence, the central pipe 10 and the lower joint body 12 are connected by thread, the connecting body 8 and the central...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination Figure 4 To describe this embodiment, the central angle of the sector block 22-1 in this embodiment is 75°-90°. Such setting is convenient for adjusting polymers with different flow rates. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination Figure 4 To describe this embodiment, the central angle of the sector block 22 - 1 in this embodiment is 78°, 80°, 82°, 85° or 90°. In this way, the flow adjustment and the adjustment inlet 26 cooperate with each other at this time, and the state of the flow adjustment is the best. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com