Installation structure of shelf assembly for refrigerator

An installation structure and assembly technology, which are applied to household refrigeration devices, applications, household appliances, etc., can solve problems such as damage to the foot hook portion 11, inconvenience in use, food falling down, etc., and achieve the effect of preventing shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

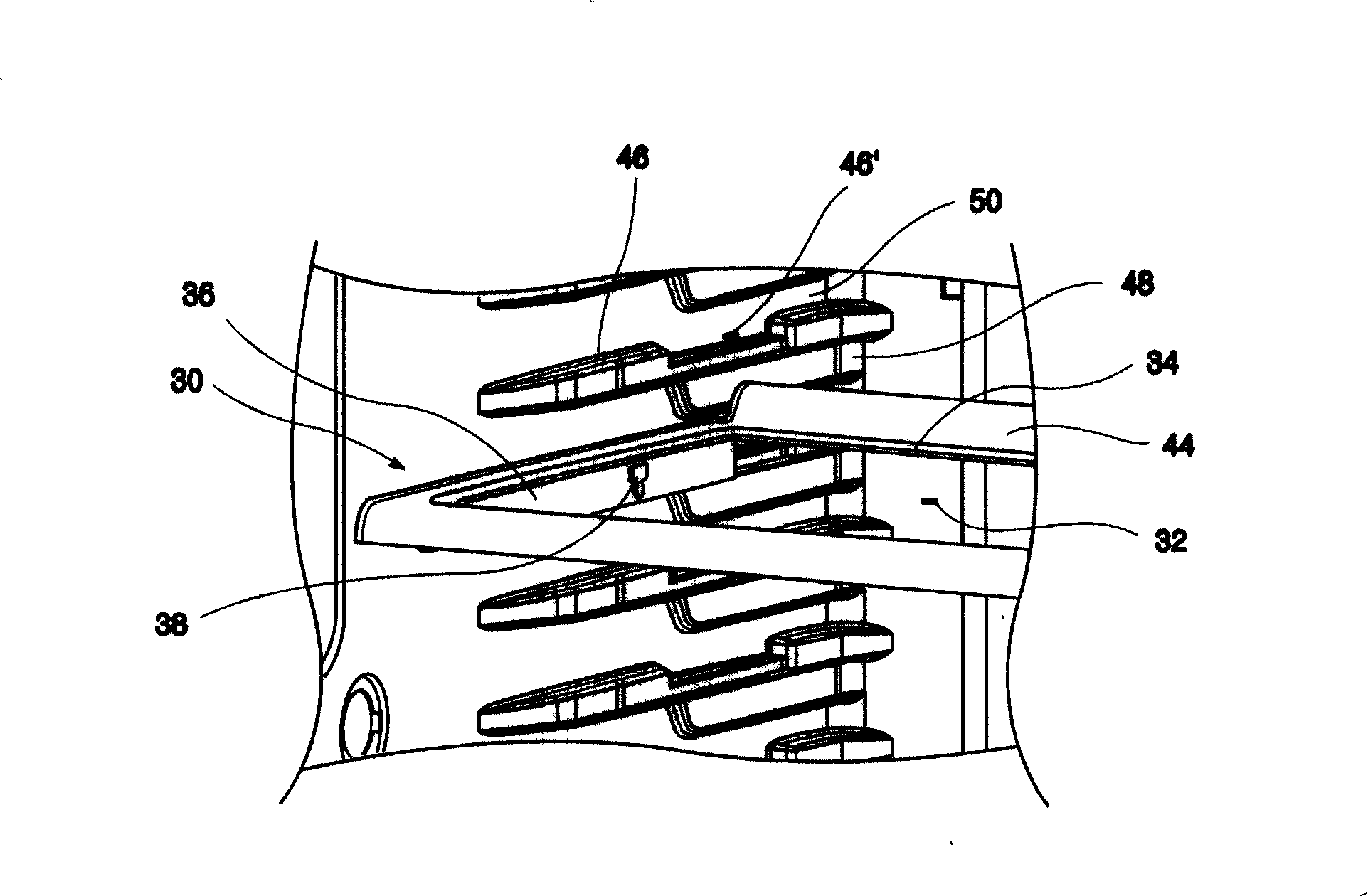

[0036] Such as image 3 , 4 As shown, the shelf frame 30 constitutes an overall frame for the placement of the shelf assembly. That is, the shelf frame 30 has a substantially rectangular frame shape, and a through-hole 32 penetrating in the vertical direction is formed inside the shelf frame 30 . A mounting end 34 is formed around the edge of the through hole 32 , and the function of the mounting end 34 is to provide a support member made of glass or plastic for covering the through hole 32 . In this embodiment, there is no drawing representation for the supporting member.

[0037] However, the present invention is not limited thereto. That is, in this embodiment, the above-mentioned shelf frame 30 and supporting components are manufactured independently to form a shelf assembly. However, the above-mentioned shelf frame 30 and the supporting member may be integrally formed.

[0038] Shielding ribs 36 are formed at both ends of the shelf frame 30 , and the shielding ribs 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com