Scale-resistant type salt elimination material-filtering corrugated tube in saline alkali soil and preparation method thereof

A technology for saline-alkali land and fouling, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of affecting the gradient ratio of hidden pipes, affecting the effect of salt discharge, poor oxidation resistance, etc., to improve the effect of salt discharge and service life, The effect of improving salt removal ability and excellent flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

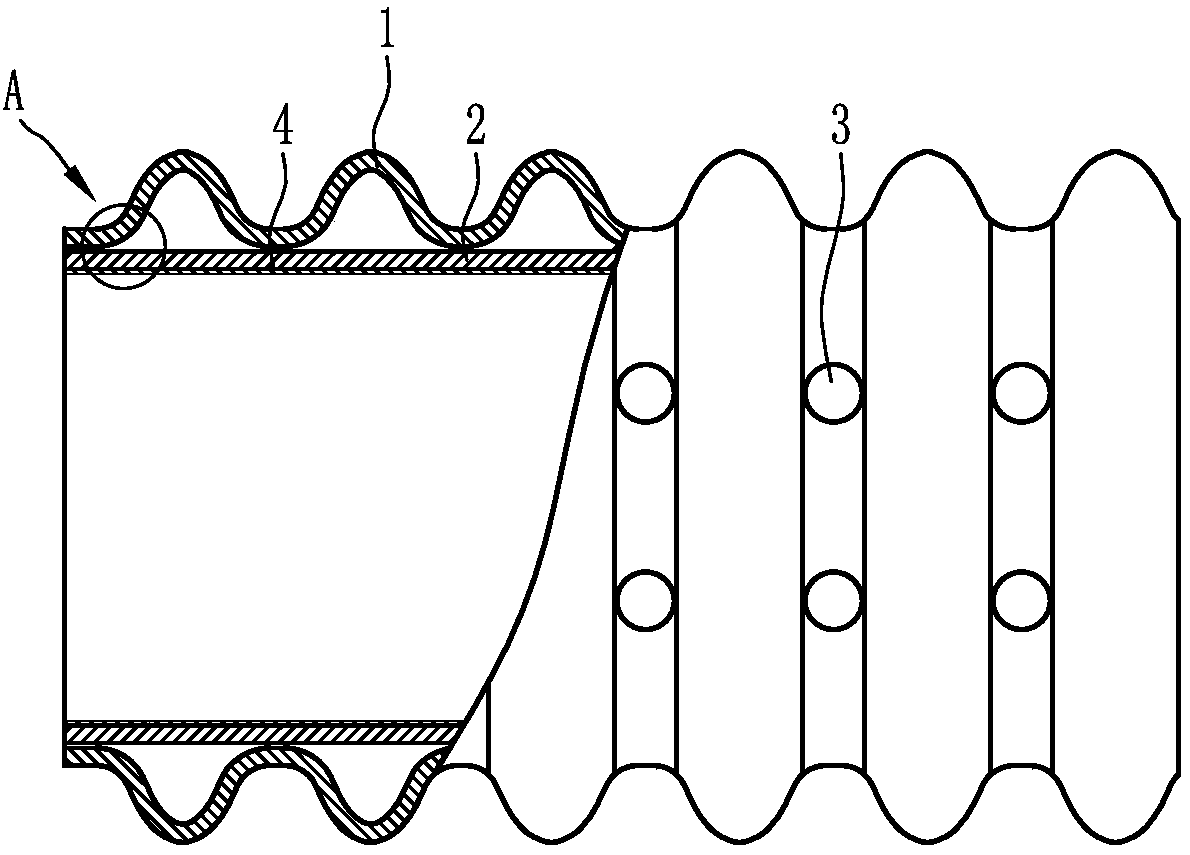

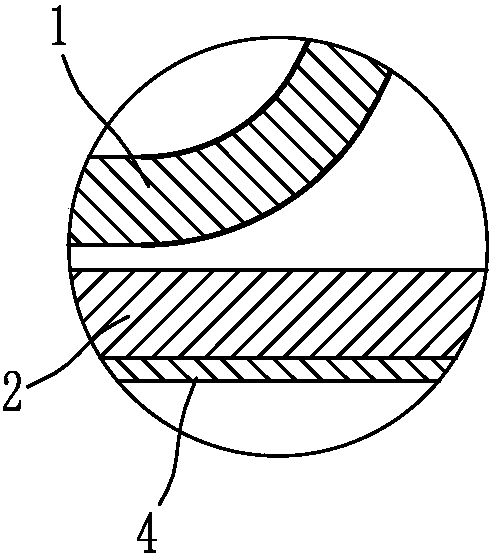

Image

Examples

Embodiment 1

[0037] In the present embodiment, the outer wall tube includes the following components by weight: 70 parts of high-density polyethylene; 15 parts of petroleum resin; 10 parts of organic fiber; 17 parts of calcium carbonate; 6 parts of rosin; 3 parts of calcium stearate; zinc oxide 3 parts; 2 parts of thiodipropionic acid; 2 parts of chlorinated paraffin;

[0038] The inner wall tube includes the following components by weight: 60 parts of rigid polyvinyl chloride; 15 parts of petroleum resin; 15 parts of calcium carbonate; 3 parts of zinc stearate; 2 parts of vinyl ester resin; 7 parts of talcum powder;

[0039] The functional hydrophobic layer is copper stearate coating.

[0040] The preparation method comprises the steps of:

[0041] Step 1, taking the raw materials of the outer wall pipe and the inner wall pipe respectively according to parts by weight;

[0042] Step 2, preparation of outer wall tube resin particles:

[0043] Mix high-density polyethylene, petroleum res...

Embodiment 2

[0052] In the present embodiment, the outer wall tube includes the following components by weight: 72 parts of high-density polyethylene; 17 parts of petroleum resin; 10 parts of organic fiber; 18 parts of calcium carbonate; 7 parts of rosin; 4 parts of calcium stearate; 3 parts; 3 parts of thiodipropionic acid; 3 parts of chlorinated paraffin;

[0053] The inner wall tube includes the following components by weight: 62 parts of hard polyvinyl chloride; 17 parts of petroleum resin; 16 parts of calcium carbonate; 3 parts of zinc stearate; 2 parts of vinyl ester resin; 8 parts of talcum powder;

[0054] The functional hydrophobic layer is copper stearate coating.

Embodiment 3

[0056] In the present embodiment, the outer wall tube includes the following components by weight: 75 parts of high-density polyethylene; 18 parts of petroleum resin; 12 parts of organic fiber; 20 parts of calcium carbonate; 8 parts of rosin; 4 parts of calcium stearate; 4 parts; 3 parts of thiodipropionic acid; 3 parts of chlorinated paraffin;

[0057] The inner wall tube includes the following components by weight: 65 parts of hard polyvinyl chloride; 18 parts of petroleum resin; 17 parts of calcium carbonate; 4 parts of zinc stearate; 3 parts of vinyl ester resin; 9 parts of talcum powder;

[0058] The functional hydrophobic layer is copper stearate coating.

[0059] Wherein, the preparation methods of Example 2 and Example 3 are basically the same as those of Example 1, and will not be repeated here.

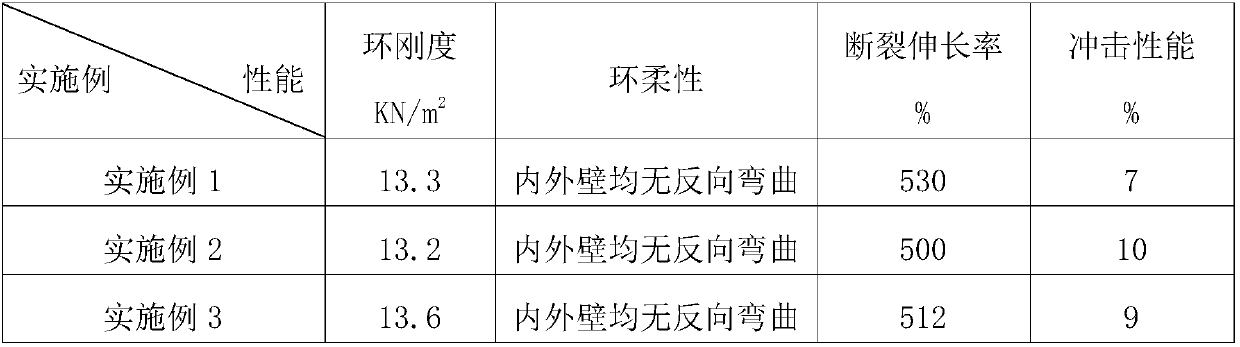

[0060] Performance Testing:

[0061] The saline-alkali land anti-fouling type salt-expelling filter wave tube prepared in Example 1, Example 2 and Example 3 was intercepte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com