Low-moisture coke quenching box and coke quenching method using same

A low-moisture, coke quenching box technology, applied in the field of coke quenching, can solve the problems of inability to accurately control the temperature of blue carbon, poor quality of blue carbon products, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

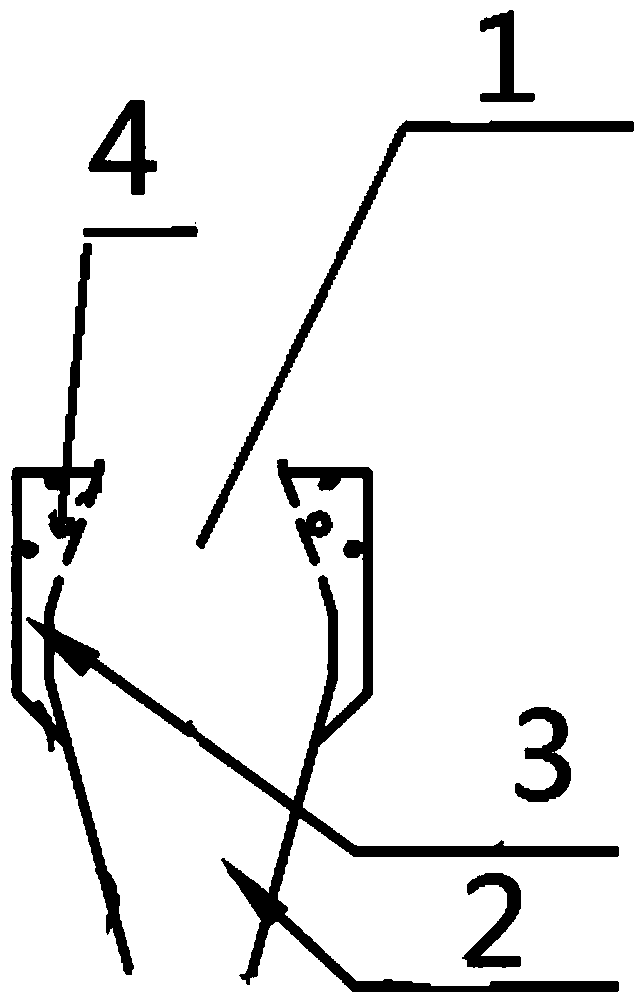

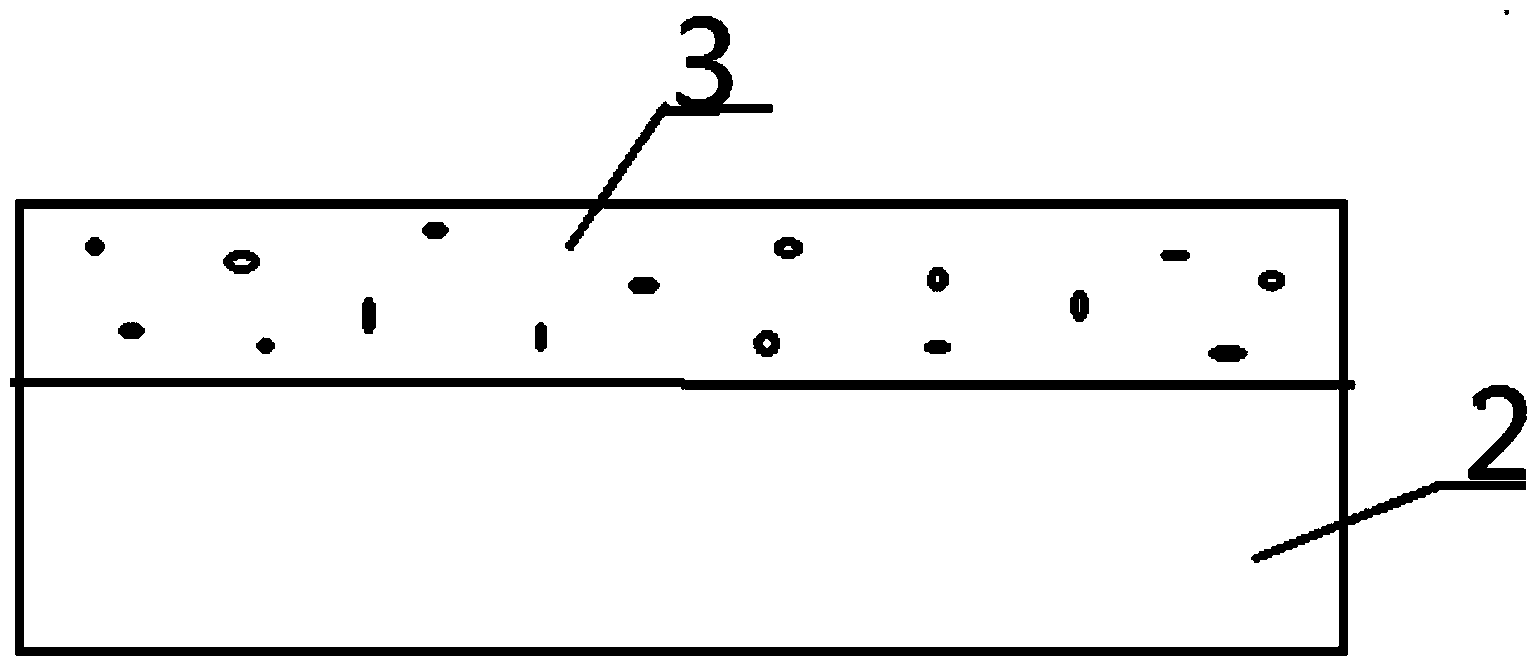

[0038] The present embodiment provides a low-moisture coke quenching box 1, such as figure 1 and figure 2 They are respectively a schematic cross-sectional structure diagram and a side view of the low-moisture coke quenching box, and its structure includes:

[0039] The coke quenching chamber 2 is arranged along the vertical direction, and the upper end of the coke quenching chamber 2 is provided with a coke inlet port, and the lower end is provided with a coke outlet port, so that the coke quenching chamber 2 is suitable for taking the coke quenching material from the inlet The coke mouth flows to the coke outlet, and the flowing coke quenching material fills the entire coke quenching chamber 2; the low-moisture coke quenching box is shaped like a long tank;

[0040] The spray chamber 3 is arranged close to the periphery of the coke quenching chamber 2, and a spray device is arranged in the spray chamber 3, and the wall surface between the spray chamber 3 and the coke quenchi...

Embodiment 2

[0051] The present embodiment provides a kind of low-moisture coke quenching box 1, and its structure comprises:

[0052] The coke quenching chamber 2 is arranged along the vertical direction, and the upper end of the coke quenching chamber 2 is provided with a coke inlet port, and the lower end is provided with a coke outlet port, so that the coke quenching chamber 2 is suitable for taking the coke quenching material from the inlet The coke mouth flows to the coke outlet, and the flowing coke quenching material fills the entire coke quenching chamber 2; the coke quenching chamber 2 in this embodiment is a cylindrical body arranged in a vertical The diameter first expands and then decreases along the height direction;

[0053] Four spray chambers 3 are arranged on both sides of the periphery of the coke quenching chamber 2, and the four spray chambers 3 are communicated through a connecting pipe 5;

[0054] A spray device is arranged in the spray chamber 3, and a through hole...

Embodiment 3

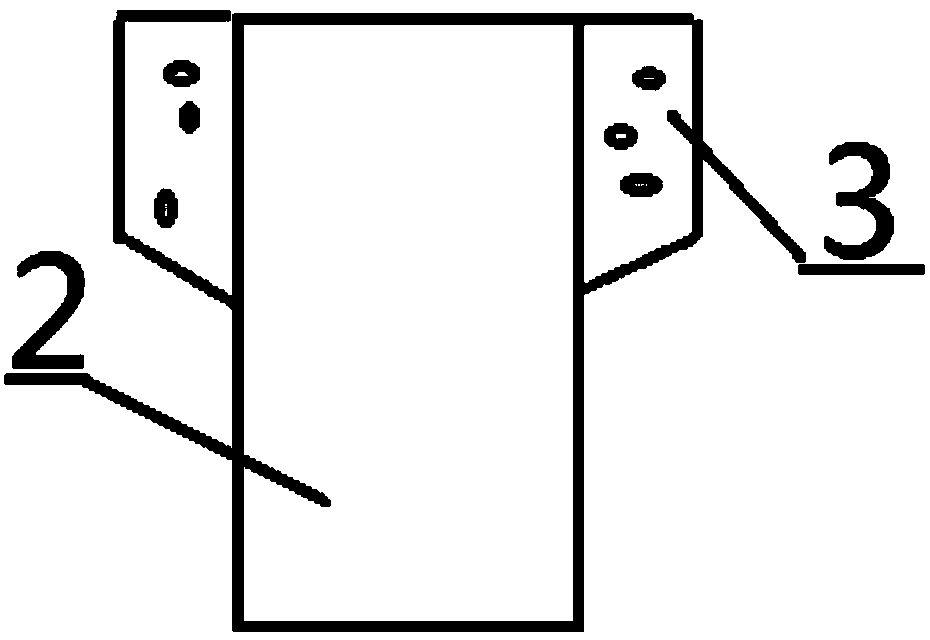

[0065] The present embodiment provides a low-moisture coke quenching box 1, such as image 3 , Figure 4 Respectively, the cross-sectional structure schematic diagram and the top view of the low-moisture coke quenching box, its structure includes:

[0066] The coke quenching chamber 2 is arranged along the vertical direction, and the upper end of the coke quenching chamber 2 is provided with a coke inlet port, and the lower end is provided with a coke outlet port, so that the coke quenching chamber 2 is suitable for taking the coke quenching material from the inlet The coke opening flows to the coke outlet, and the flowing coke quenching material fills the entire cavity of the coke quenching chamber 2; the coke quenching chamber 2 in this embodiment is a cylindrical body with a constant diameter;

[0067] Four spray chambers 3 are arranged on both sides of the periphery of the coke quenching chamber 2, and the four spray chambers 3 are communicated through a connecting pipe 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com