High-efficiency and environment-friendly construction waste crushing device

A technology of construction waste and crushing device, which is used in presses, grain processing, manufacturing tools, etc., to achieve the effect of facilitating crushing, prolonging the service life of equipment, and improving the working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

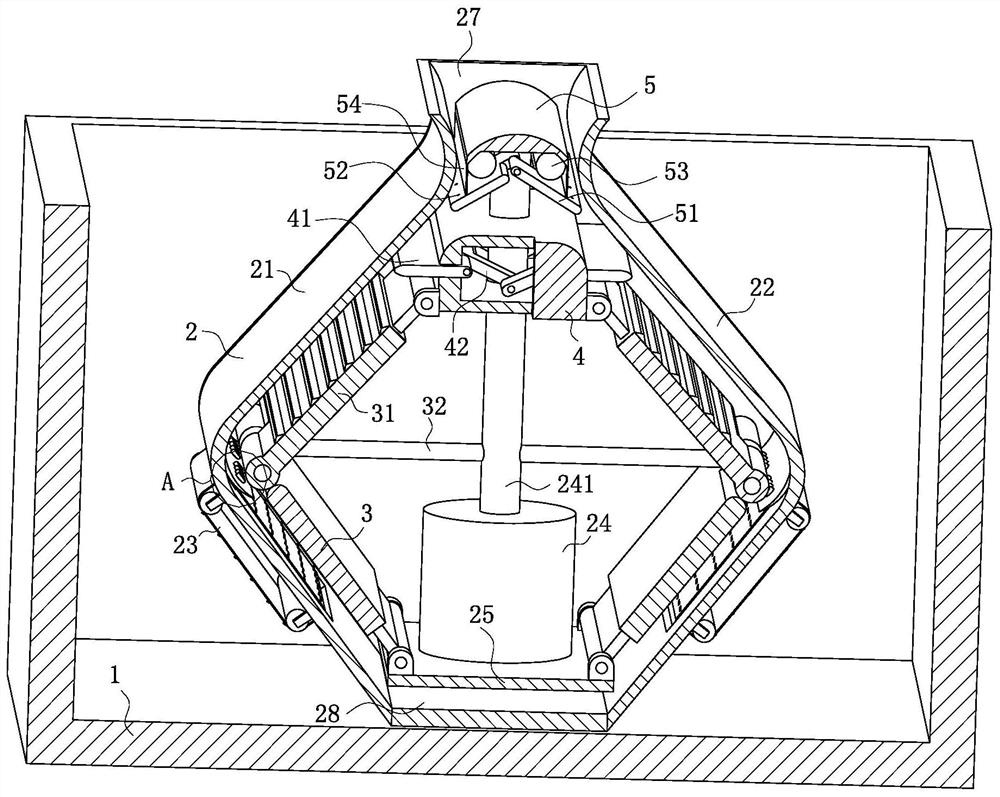

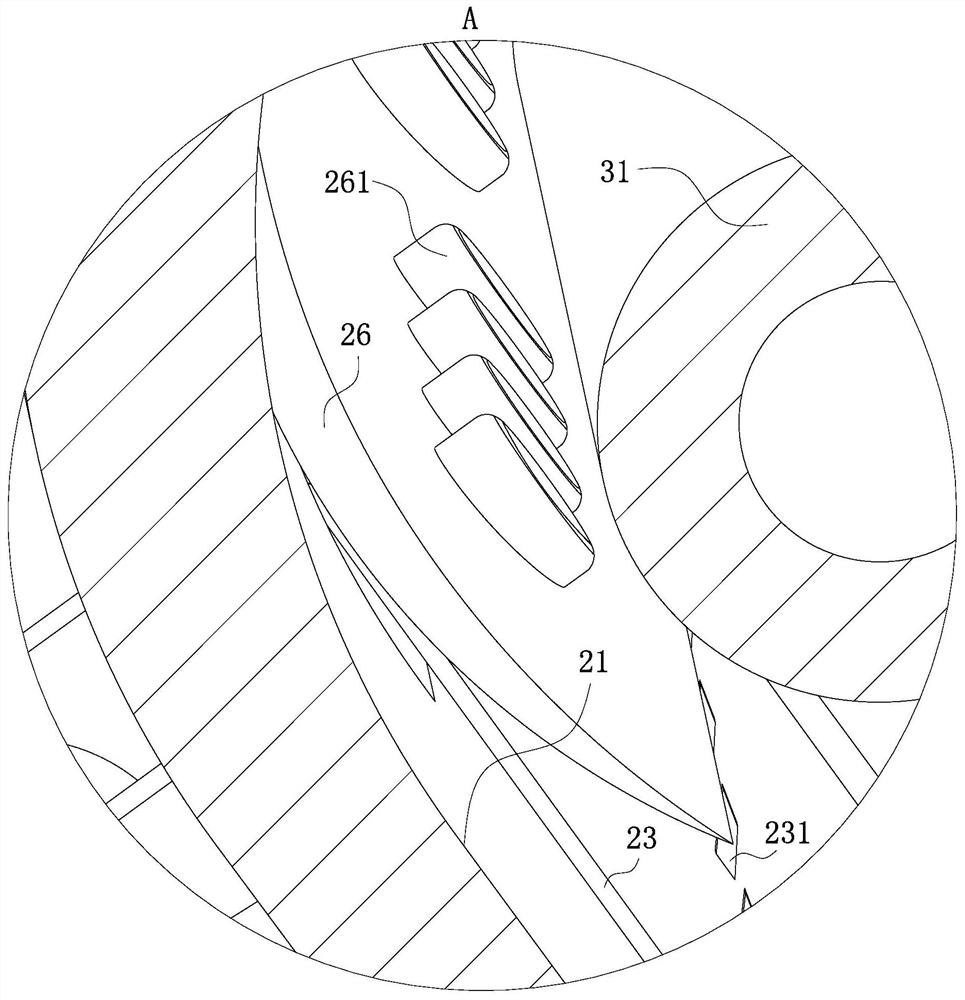

[0029] As an embodiment of the present invention, the top of the piston rod 241 is fixedly equipped with an arc-shaped plate 5; the highest point of the arc-shaped plate 5 is lower than the highest point of the left baffle plate 21; the piston rod 241 is hinged with Movable plate 51; said movable plate 51 has two, symmetrically distributed left and right; said movable plate 51 is located below the arc plate 5; said movable plate 51 is located above the platform plate 4;

[0030] During work, when the piston rod 241 moves upwards, the movable plate 51 hinged on the piston rod 241 is close to the piston rod 241 and moves upwards with the piston rod 241, and is inserted between the concrete blocks; when the piston rod 241 moves downwards, The movable plate 51 is blocked by the concrete block, and rotates upwards until it is blocked by the arc plate 5 at the top of the piston rod 241, and then the downward movable plate 51 squeezes the concrete block downwards, so that the concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com